What is a Packaging Machine and a Packing Machine?

leading paragraph:

Ever wondered about the difference between a "packaging" and a "packing" machine? They're not the same!

snippet paragraph:

A packaging machine creates the final, consumer-facing package with features like shape, design, sealing, and labeling. A packing machine groups and prepares products for shipping or storage, often involving bulk packaging and protection during transport. While related, they have distinct roles in the product handling process.

Transition Paragraph:

Let's clarify the specific functions of each type of machine and how they fit into the overall production line.

What is a Packing Machine?

leading paragraph:

What exactly does a packing machine do?

snippet paragraph:

A packing machine prepares products for shipping and storage. This includes tasks like boxing, wrapping, palletizing, and applying protective materials to ensure safe transport.

Key Functions of a Packing Machine

- Boxing: Placing products into cardboard boxes or containers.

- Wrapping: Applying protective layers like stretch film or shrink wrap.

- Palletizing: Stacking and securing boxes onto pallets for efficient transport.

- Strapping: Securing boxes or pallets with plastic or metal straps.

- Labeling: Applying shipping labels with destination and tracking information.

Dive deeper Paragraph:

Packing machines are the unsung heroes of the supply chain, ensuring that products arrive safely and efficiently at their final destination. These machines automate the process of preparing products for shipping and storage, reducing labor costs and increasing throughput. From boxing and wrapping to palletizing and strapping, packing machines handle a variety of tasks that would be time-consuming and labor-intensive if done manually. They also help to protect products from damage during transport by applying protective layers and securing them in place. I remember touring a large distribution center and being amazed by the sheer speed and efficiency of the packing machines, which could process hundreds of boxes per hour.

What Does a Packer Machine Do?

leading paragraph:

Is a "packer machine" the same as a "packing machine?"

snippet paragraph:

"Packer machine" is essentially another term for a packing machine. It performs the same functions: grouping, protecting, and preparing products for shipment or storage.

Synonymous Functions

- Grouping Products: Assembling multiple items into a single package.

- Protecting Products: Applying cushioning materials to prevent damage.

- Preparing for Shipment: Labeling and documenting packages for transport.

- Automating Processes: Reducing manual labor and increasing efficiency.

- Ensuring Safe Transport: Minimizing the risk of damage during shipping.

Dive deeper Paragraph:

The terms "packer machine" and "packing machine" are often used interchangeably, so don't let the slight difference in terminology confuse you. Both types of machines perform the same basic functions: grouping products together, protecting them from damage, and preparing them for shipment or storage. Whether it's boxing, wrapping, palletizing, or strapping, these machines are designed to automate the packing process, reducing the need for manual labor and increasing efficiency. By ensuring that products are properly packed and protected, packer machines play a crucial role in minimizing the risk of damage during shipping and ensuring that customers receive their orders in good condition.

What Equipment is Used for Packaging?

leading paragraph:

What tools and machines are involved in creating the consumer-facing package?

snippet paragraph:

Packaging equipment includes: 1) Filling machines 2) Sealing machines 3) Labeling machines 4) Form-fill-seal machines 5) Shrink wrappers. These machines create the primary package that consumers see.

Types of Packaging Equipment

- Filling Machines: Dispense products into containers (bottles, pouches, etc.).

- Sealing Machines: Close and seal containers to preserve freshness.

- Labeling Machines: Apply labels with product information and branding.

- Form-Fill-Seal Machines: Create, fill, and seal packages in a single process.

- Shrink Wrappers: Apply shrink film to create a tight seal around products.

Dive deeper Paragraph:

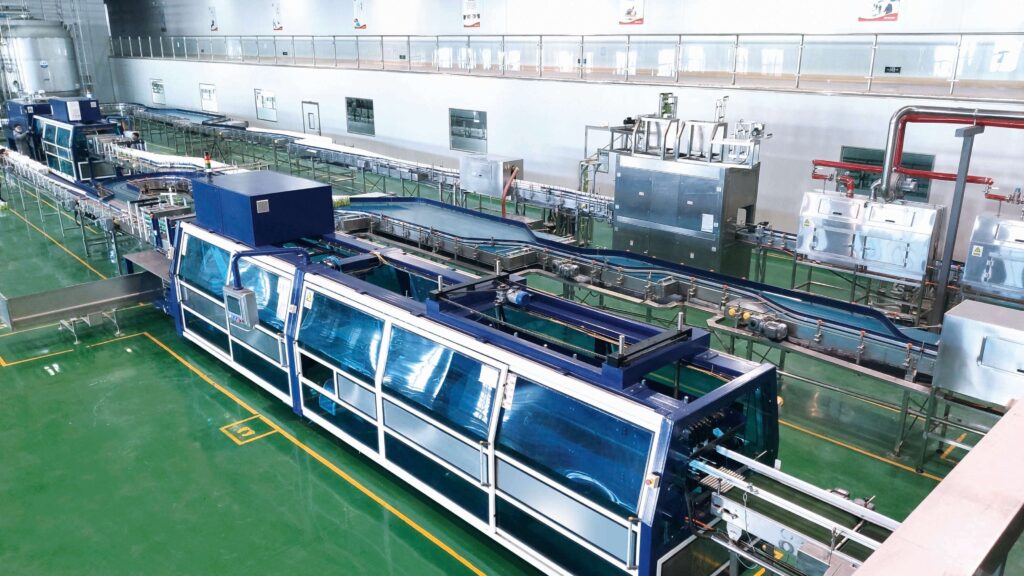

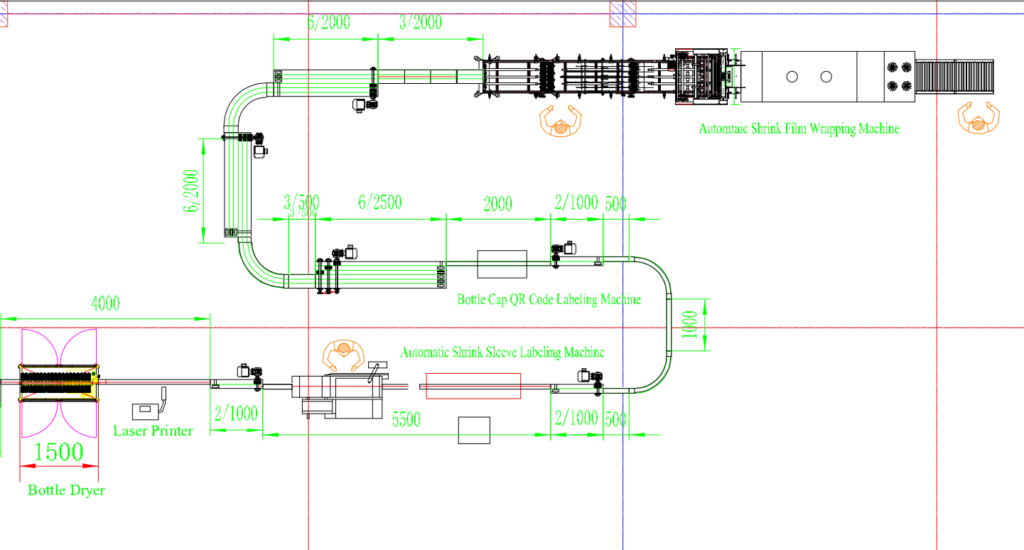

Packaging equipment is designed to create the primary package that consumers see on store shelves. These machines automate the process of filling containers with product, sealing them to preserve freshness, and applying labels with product information and branding. Form-fill-seal machines are particularly versatile, as they can create, fill, and seal packages in a single continuous process. Shrink wrappers apply a layer of shrink film to create a tight seal around products, providing an extra layer of protection and enhancing their visual appeal. The specific type of packaging equipment used will depend on the type of product being packaged and the desired packaging format.

What Are Some of the General Types of Packaging Machines?

leading paragraph:

Can we categorize packaging machines by their main function?

snippet paragraph:

General types of packaging machines include: 1) Blister packaging machines 2) Cartoning machines 3) Flow wrapping machines 4) Case erectors 5) Palletizers. Each type serves a specific purpose in the packaging process.

Types of Packaging Machines and Their Uses

- Blister Packaging Machines: Create blister packs for pharmaceuticals and small items.

- Cartoning Machines: Form, fill, and close cardboard cartons.

- Flow Wrapping Machines: Wrap products in a horizontal flow of film.

- Case Erectors: Automatically form and erect cardboard boxes.

- Palletizers: Stack and arrange boxes onto pallets.

Dive deeper Paragraph:

Packaging machines come in a wide variety of types, each designed for a specific purpose in the packaging process. Blister packaging machines create those familiar blister packs that protect pharmaceuticals and small items. Cartoning machines form, fill, and close cardboard cartons, which are commonly used for packaging food products, cosmetics, and other consumer goods. Flow wrapping machines wrap products in a horizontal flow of film, creating a tight and protective seal. Case erectors automatically form and erect cardboard boxes, which are then used to pack products for shipment. And finally, palletizers stack and arrange boxes onto pallets, preparing them for efficient transport.

Conclusion

Packaging machines create the consumer-facing package, while packing machines prepare products for shipping. Understanding the difference is crucial for optimizing your production line and ensuring your products are both appealing and protected during transport.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.