What do I need to start a soda factory?

Leading paragraph:

Dreaming of creating your own fizzy concoctions? Starting a soda factory might be closer than you think!

Snippet paragraph:

Starting a soda factory requires financial resources, a solid business plan, and adherence to regulations. This includes defining your target market, creating a unique product, securing licenses, acquiring equipment, and setting up distribution.

Transition Paragraph:

Let's explore the key steps and considerations to turn your soda-making dreams into reality.

How much does it cost to start a soda company?

Leading paragraph:

So, you're thinking about launching your own soda brand? Let's talk numbers – how much will it actually cost?

Snippet paragraph:

The cost to start a soda company varies widely, from $150,000 to $500,000 or more. It depends on the scale of your operation, the equipment you choose, and your marketing strategy.

Dive deeper Paragraph:

The initial investment for a soda company can be broken down into several key areas. First, there's the cost of equipment. This includes everything from mixing tanks and carbonation systems to bottling or canning lines. You can start with smaller, semi-automatic machines to save money, but keep in mind that this might limit your production volume.

Next, consider the cost of raw materials. You'll need ingredients like sweeteners, flavorings, and carbon dioxide. These costs can fluctuate, so it's essential to establish reliable supply chains.

Then, there are operational expenses such as rent for your production facility, utilities, and employee wages. You'll also need to factor in costs for packaging, labeling, and marketing.

Finally, don't forget about legal and regulatory compliance. You'll need to obtain the necessary licenses and permits, which can vary depending on your location. Here’s a table to give you a clearer picture:

| Expense Category | Estimated Cost Range | Notes |

|---|---|---|

| Equipment | $100,000 - $200,000+ | Varies based on automation and production capacity. |

| Raw Materials | $20,000 - $50,000+ | Depends on the scale and ingredients. |

| Operational Expenses | $10,000 - $100,000+ | Includes rent, utilities, wages. |

| Packaging & Marketing | $10,000 - $50,000+ | Costs for bottles/cans, labels, and marketing efforts. |

| Legal & Regulatory | $10,000 - $10,000+ | Licenses, permits, and compliance costs. |

Starting a soda company requires careful financial planning. It's important to create a detailed budget and consider all potential expenses before you launch.

What is the cost of a soda factory?

Leading paragraph:

Building a soda empire? Let's break down the costs involved in setting up a soda factory.

Snippet paragraph:

The cost of a soda factory ranges from $100,000 to several million dollars. This depends on the size of the facility, the level of automation, and the production capacity you aim for.

Dive deeper Paragraph:

Setting up a soda factory involves significant investment in infrastructure, equipment, and technology. The scale of your operation will heavily influence the final cost. A small-scale factory focusing on niche markets will have different requirements than a large-scale facility aiming for mass production.

Here’s a look at some of the critical cost components:

- Facility: Renting or purchasing a suitable facility is a major expense. The size and location will affect the cost.

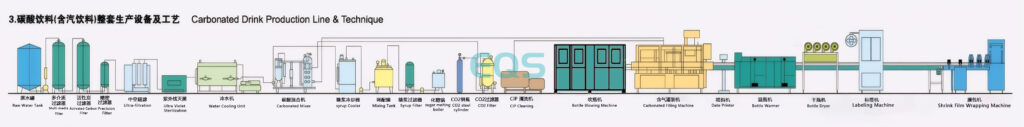

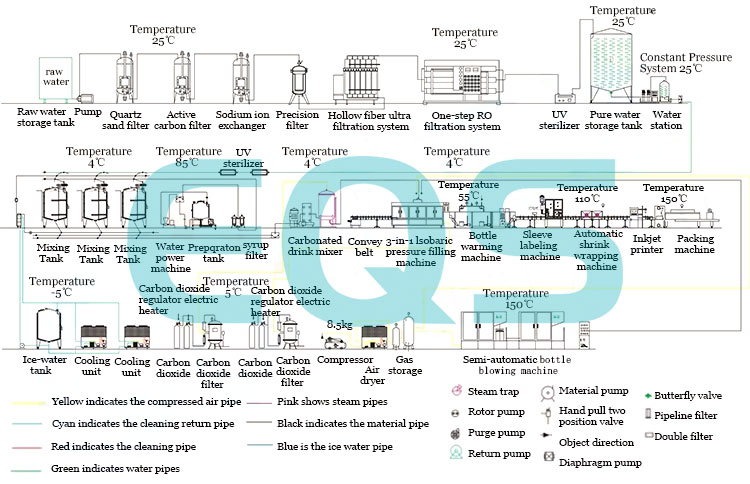

- Equipment: This includes mixing tanks, carbonation systems, filling machines, labeling machines, and packaging equipment.

- Utilities: Soda factories consume a lot of electricity and water.

- Automation: Investing in automated systems can increase efficiency but also adds to the initial cost.

- Quality Control: Setting up a lab for quality testing is essential to ensure product consistency and safety.

When EQS helps clients set up soda factories, we often advise them to consider a phased approach. Start with essential equipment and gradually upgrade as your business grows. For example, all beverage production lines need labeling machines, coding machines, film wrapping machines or carton packaging machines, and palletizing machines. Some clients with small production volumes might not need blowing machines, and those with low budgets often opt for semi-automatic labeling equipment for the back end. If the client's production volume is in the range of 2000BPH to 10000BPH, we recommend equipping a three-in-one filling machine, which integrates rinsing, filling, and capping. For clients with production volumes exceeding 10000BPH, up to 54000BPH, we suggest using a blow-fill-seal machine, which combines blowing, filling, and sealing.

How profitable is the soft drink industry?

Leading paragraph:

Is the soft drink industry a goldmine, or is it fizzling out? Let's examine the profit potential.

Snippet paragraph:

The soft drink industry is highly profitable, with a global market worth billions of dollars. However, profitability varies depending on factors like brand recognition, distribution channels, and production costs.

Dive deeper Paragraph:

The soft drink industry's profitability is driven by several factors, including high consumption rates, strong brand loyalty, and effective marketing. Major players like Coca-Cola and PepsiCo have built iconic brands that command premium prices. However, the industry is also facing challenges such as changing consumer preferences, health concerns about sugary drinks, and increasing competition from alternative beverages.

Here's a breakdown of the key factors affecting profitability:

- Brand Strength: Well-known brands can charge higher prices and attract more customers.

- Distribution Network: Efficient distribution channels are crucial for getting your product to market.

- Production Costs: Managing production costs, including raw materials and labor, is essential for maintaining profit margins.

- Marketing: Effective marketing campaigns can drive sales and increase brand awareness.

- Innovation: Developing new and appealing products can attract new customers and keep existing ones engaged.

To succeed in the soft drink industry, you need a strong brand, efficient operations, and a deep understanding of your target market. It's also important to stay ahead of trends and adapt to changing consumer preferences.

How much does it cost to make soda?

Leading paragraph:

Ever wondered about the actual cost of producing that fizzy drink you love? Let's uncover the economics of soda making.

Snippet paragraph:

The cost to make soda ranges from $0.05 to $0.30 per can or bottle. This includes ingredients, packaging, labor, and overhead expenses.

Dive deeper Paragraph:

The cost of making soda is influenced by several factors, including the price of raw materials, the efficiency of your production process, and the scale of your operation. Larger companies can often negotiate better deals with suppliers and benefit from economies of scale.

Here's a closer look at the cost components:

- Ingredients: Sweeteners, flavorings, carbon dioxide, and water are the main ingredients.

- Packaging: Cans, bottles, labels, and cartons contribute significantly to the cost.

- Labor: Wages for production workers, quality control staff, and management.

- Overhead: Rent, utilities, insurance, and administrative expenses.

To reduce the cost of making soda, you can focus on optimizing your production process, negotiating better deals with suppliers, and minimizing waste. Investing in energy-efficient equipment can also help lower your utility bills.

Conclusion

Starting a soda factory is a complex but potentially rewarding venture. With careful planning, sound financial management, and a unique product, you can carve out a successful niche in the competitive beverage market.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.