What Automated Functions Can the Beer Can Line Achieve?

leading paragraph:

Thinking about automating your beer canning? Here's what's possible!

snippet paragraph:

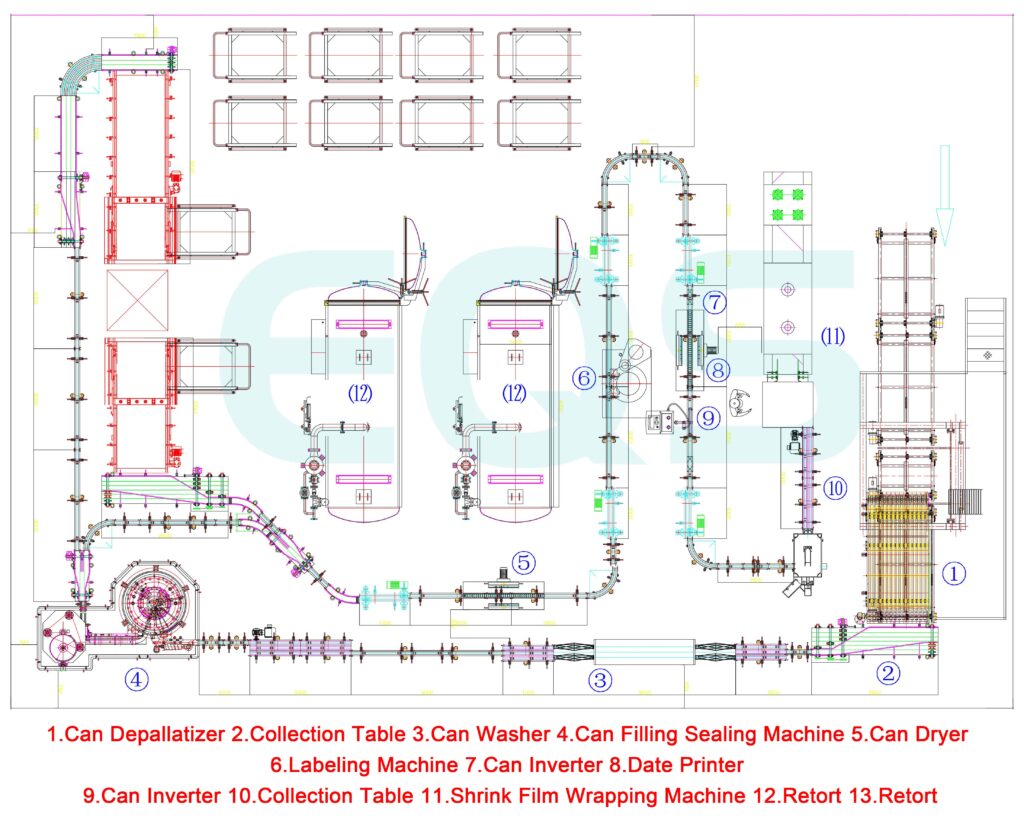

An automated beer can line can achieve a wide range of functions, including can depalletizing, washing, CIP (Cleaning In Place), filling, sealing, pasteurization, drying, labeling, inverting, packing, and palletizing. These automated processes streamline production, reduce labor, and ensure consistent quality from start to finish.

Transition Paragraph:

Let's dive into the specific automated functions that make a beer can line so efficient.

Can Depalletizing: Automated Can Unloading

leading paragraph:

No more manual can stacking!

snippet paragraph:

The can depalletizer automates the unloading of empty cans from pallets. This machine efficiently removes layers of cans and feeds them onto the production line, reducing manual labor and preventing can damage. Automated depalletizing ensures a smooth and continuous supply of cans for the filling process.

Depalletizing Benefits

- Reduced Manual Labor: Automates can unloading.

- Prevents Can Damage: Gentle handling of cans.

- Continuous Supply: Smooth can feeding.

- Increased Efficiency: Faster unloading process

- Space Optimization: Compact design options

Dive deeper Paragraph:

Can depalletizing is the first step in the automated beer can line, and it plays a crucial role in streamlining the production process. This machine automates the unloading of empty cans from pallets, reducing manual labor and preventing can damage.

Reduced Manual Labor

Manual can unloading is a labor-intensive task that can be time-consuming and physically demanding. The can depalletizer automates this process, freeing up workers to focus on other tasks.

Prevents Can Damage

The can depalletizer is designed to handle cans gently, preventing damage that can occur during manual unloading. This helps to reduce waste and ensure that all cans are in good condition for filling.

Can Washing: Ensuring Cleanliness

leading paragraph:

Clean cans are a must for quality beer!

snippet paragraph:

The can washer automatically cleans empty cans before filling. This machine removes dust, debris, and contaminants, ensuring the cans are sanitized and ready for the filling process. Clean cans are essential for maintaining the quality and safety of the beer.

Washing Benefits

- Removes Contaminants: Ensures cans are sanitized.

- Maintains Beer Quality: Prevents contamination.

- Automated Cleaning: Efficient and consistent.

- Hygienic Operation: Minimizes bacteria

- Water Conservation: Optimized washing cycles

Dive deeper Paragraph:

Can washing is an essential step in the automated beer can line, ensuring that the empty cans are clean and sanitized before they are filled with beer. This machine removes dust, debris, and contaminants, maintaining the quality and safety of the beer.

Removes Contaminants

The can washer uses a combination of water and cleaning agents to remove contaminants from the cans. This ensures that the cans are free of any substances that could affect the taste or quality of the beer.

Maintains Beer Quality

By removing contaminants from the cans, the can washer helps to maintain the quality of the beer. This ensures that the beer tastes as it should and that it is safe to drink.

CIP (Cleaning In Place) System: Automated Cleaning

leading paragraph:

Keeping the whole system spotless!

snippet paragraph:

The CIP system automates the cleaning and sanitizing of the entire filling line. This system circulates cleaning solutions through the equipment, removing residue and bacteria without manual disassembly. Automated CIP ensures a hygienic production environment and reduces downtime for cleaning.

CIP Benefits

- Automated Cleaning: No manual disassembly required.

- Hygienic Production: Reduces bacteria and residue.

- Reduced Downtime: Faster cleaning cycles.

- Consistent Cleaning: Reliable sanitation

- Chemical Optimization: Efficient use of cleaning agents

Dive deeper Paragraph:

The CIP (Cleaning In Place) system is a critical component of the automated beer can line, ensuring that the entire filling line is clean and sanitized. This system automates the cleaning process, reducing downtime and ensuring a hygienic production environment.

Automated Cleaning

The CIP system automates the cleaning process, eliminating the need for manual disassembly and cleaning of the equipment. This saves time and reduces the risk of human error.

Hygienic Production

By circulating cleaning solutions through the equipment, the CIP system removes residue and bacteria, ensuring a hygienic production environment. This helps to maintain the quality and safety of the beer.

Filling Sealing Monoblock Machine: Precision Filling and Sealing

leading paragraph:

The heart of the canning process!

snippet paragraph:

The filling-sealing monoblock machine combines the filling and sealing processes into one unit. This machine accurately fills cans with beer and then immediately seals them to prevent oxygen exposure and maintain carbonation. Automated filling and sealing ensures consistent fill levels and airtight seals for optimal beer quality.

Filling Sealing Benefits

- Accurate Filling: Consistent fill levels.

- Airtight Seals: Prevents oxygen exposure.

- Combined Process: Efficient and streamlined.

- Reduced Wastage: Precise measurements

- Maintained Carbonation: Quality sealing technology

Dive deeper Paragraph:

The filling-sealing monoblock machine is the heart of the automated beer can line, combining the filling and sealing processes into one efficient unit. This machine ensures that cans are filled accurately and sealed tightly to maintain the quality and carbonation of the beer.

Accurate Filling

The filling machine uses precise filling mechanisms to ensure that each can is filled with the correct amount of beer. This helps to maintain consistent fill levels and prevent overfilling or underfilling.

Airtight Seals

The sealing machine creates airtight seals on the cans, preventing oxygen exposure and maintaining carbonation. This is essential for preserving the taste and quality of the beer.

Pasteurizer Tunnel: Ensuring Product Stability

leading paragraph:

Keeping beer fresh for longer!

snippet paragraph:

The pasteurizer tunnel gently heats the filled and sealed cans to eliminate spoilage microorganisms. This process extends the shelf life of the beer without compromising its flavor. Automated pasteurization ensures consistent and reliable results, safeguarding the beer's quality during storage and distribution.

Pasteurization Benefits

- Extended Shelf Life: Prevents spoilage.

- Maintained Flavor: Gentle heating process.

- Consistent Results: Reliable pasteurization.

- Quality Assurance: Ensures product safety

- Distribution Flexibility: Wider market reach

Dive deeper Paragraph:

The pasteurizer tunnel is an important component of the automated beer can line, ensuring that the beer has a long shelf life and maintains its quality during storage and distribution. This machine gently heats the filled and sealed cans to eliminate spoilage microorganisms.

Extended Shelf Life

Pasteurization extends the shelf life of the beer by killing any microorganisms that could cause spoilage. This allows the beer to be stored for longer periods of time without losing its quality.

Maintained Flavor

The pasteurization process is carefully controlled to ensure that the flavor of the beer is not compromised. The beer is heated gently to eliminate microorganisms without causing any changes to its taste or aroma.

Can Dryer: Removing Moisture

leading paragraph:

Dry cans are ready for labeling!

snippet paragraph:

The can dryer removes moisture from the cans after pasteurization or washing. This machine uses air knife drying the cans quickly and efficiently, preparing them for labeling and packing. Dry cans ensure proper label adhesion and prevent corrosion during storage.

Drying Benefits

- Proper Label Adhesion: Ensures labels stick securely.

- Prevents Corrosion: Keeps cans dry during storage.

- Efficient Drying: Quick and effective process.

- Reduced Smudging: Clearer label appearance

- Prevents Mold: Safeguards can integrity

Dive deeper Paragraph:

The can dryer is an essential part of the automated beer can line, ensuring that the cans are dry before they are labeled and packed. This machine removes moisture from the cans, preventing corrosion and ensuring proper label adhesion.

Proper Label Adhesion

Dry cans are essential for ensuring that labels stick securely. Moisture can prevent labels from adhering properly, which can lead to labels peeling off during storage or transportation.

Prevents Corrosion

Moisture can cause cans to corrode, which can affect the quality and safety of the beer. The can dryer removes moisture, preventing corrosion and ensuring that the cans remain in good condition.

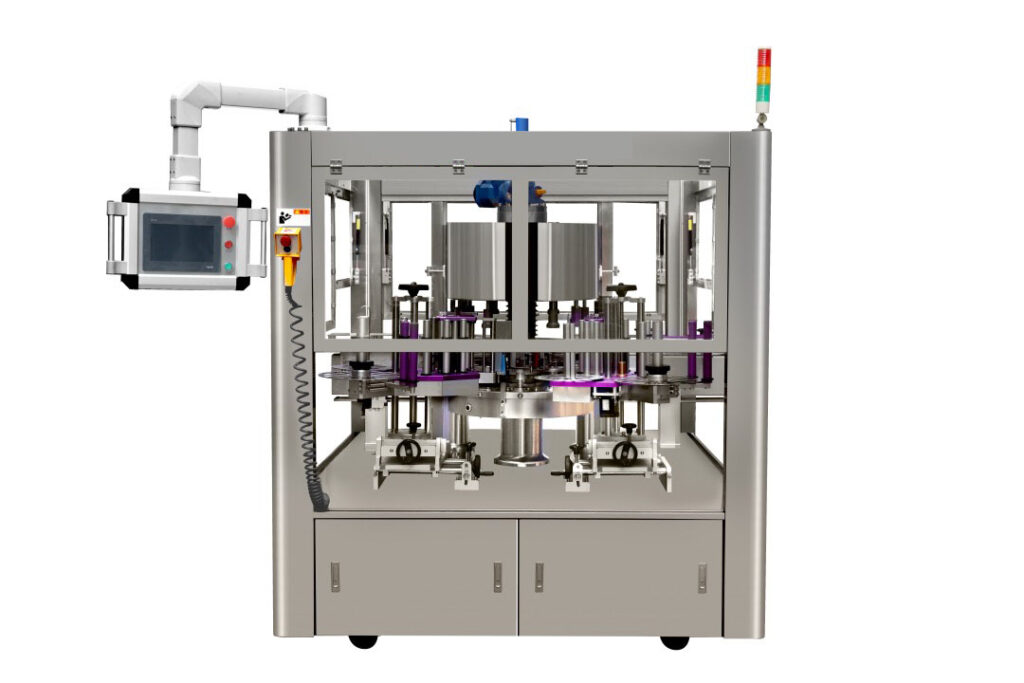

Labeling Machine: Applying Labels

leading paragraph:

Making sure every can is branded perfectly!

snippet paragraph:

The labeling machine automatically applies labels to the dried cans. This machine ensures accurate label placement and secure adhesion, providing important product information and branding. Automated labeling enhances the appearance of the cans and improves product recognition.

Labeling Benefits

- Accurate Placement: Ensures labels are correctly positioned.

- Secure Adhesion: Prevents labels from peeling off.

- Product Information: Provides important details.

- Enhanced Branding: Improves shelf appeal

- High-Speed Application: Fast and efficient labeling

Dive deeper Paragraph:

The labeling machine is an important component of the automated beer can line, applying labels to the dried cans and providing important product information and branding. This machine ensures accurate label placement and secure adhesion.

Accurate Placement

The labeling machine is designed to place labels accurately on the cans, ensuring that they are positioned correctly. This is important for providing clear and easy-to-read product information.

Secure Adhesion

The labeling machine uses adhesive to securely attach labels to the cans, preventing them from peeling off during storage or transportation. This ensures that the labels remain in place and that the product information remains visible.

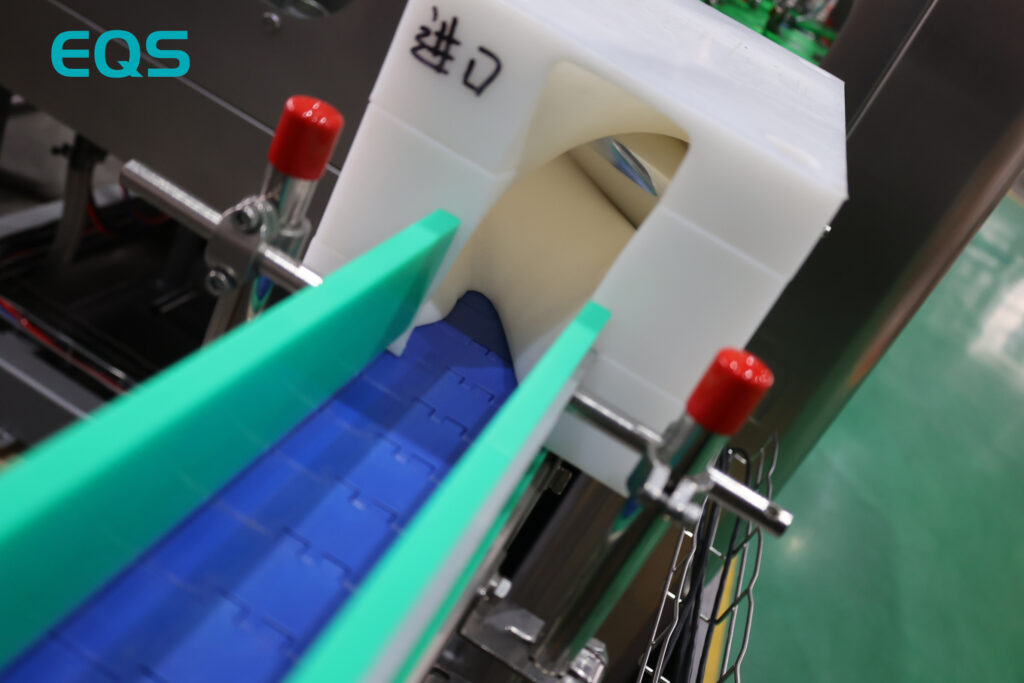

Can Inverter: Ensuring Product Quality

leading paragraph:

Flipping cans to ensure smooth production!

snippet paragraph:

The can inverter on the beer can production line is mainly used to adjust the direction of the can, so as to carry out subsequent processes such as cleaning, filling and capping, so as to ensure smooth production process and product quality.

Inverting Benefits

- Preparation for cleaning: Flipping cans for better cleaning.

- Precision filling: Flip the can over after cleaning and align with the filling valve.

- Lableing: It’s required when print the production data and batch on the bottom of cans.

Dive deeper Paragraph:

The can inverter plays a key role in connecting different processes and adjusting the posture of the can body in the beer can production line. It ensures the smoothness and efficiency of the production process, and ultimately ensures the quality and health safety of the product.

Packing Machine: Preparing for Shipping

leading paragraph:

Grouping cans for easy transport!

snippet paragraph:

The packing machine automatically groups and packs the labeled cans into cartons or trays. This machine ensures efficient and secure packaging for shipping and distribution. Automated packing reduces labor costs and protects the cans from damage during transport.

Packing Benefits

- Efficient Packaging: Groups cans quickly.

- Secure Transport: Protects cans from damage.

- Reduced Labor: Automates the packing process.

- Consistent Packaging: Uniform box appearance

- Space Optimization: Maximizes box fill

Dive deeper Paragraph:

The packing machine is a critical component of the automated beer can line, preparing the labeled cans for shipping and distribution. This machine automatically groups and packs the cans into cartons or trays, ensuring efficient and secure packaging.

Efficient Packaging

The packing machine is designed to group cans quickly and efficiently, reducing the time and labor required for packing. This helps to streamline the production process and increase throughput.

Secure Transport

The packing machine packs the cans into cartons or trays that are designed to protect them from damage during transport. This ensures that the cans arrive at their destination in good condition.

Palletizer System: Stacking for Distribution

leading paragraph:

Stacking boxes perfectly on pallets!

snippet paragraph:

The palletizer system automatically stacks the packed cartons onto pallets for efficient storage and distribution. This machine ensures stable and secure pallet loads, reducing the risk of damage during handling and transport. Automated palletizing maximizes storage space and streamlines the logistics process.

Palletizing Benefits

- Efficient Stacking: Automates pallet loading.

- Secure Loads: Reduces damage during transport.

- Maximized Storage: Optimizes space utilization.

- Reduced Labor: Decreases manual lifting

- Improved Safety: Minimizes workplace injuries

Dive deeper Paragraph:

The palletizer system is the final step in the automated beer can line, preparing the packed cartons for storage and distribution. This machine automatically stacks the cartons onto pallets, ensuring stable and secure pallet loads.

Efficient Stacking

The palletizer system automates the process of stacking cartons onto pallets, reducing the time and labor required for this task. This helps to streamline the production process and increase throughput.

Secure Loads

The palletizer system is designed to create stable and secure pallet loads, reducing the risk of damage during handling and transport. This ensures that the cartons arrive at their destination in good condition.

Conclusion

Automated beer can lines can do so much! From cleaning to packing, they make the whole process efficient and consistent.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.