What are the Different Types of Plastic PET Bottle Machines?

leading paragraph:

Looking for the right PET bottle machine? There are several types to choose from!

snippet paragraph:

Plastic PET bottle machines can be categorized by automation level (fully automatic vs. semi-automatic) and production capacity (linear vs. rotary). Fully automatic machines minimize manual labor, while semi-automatic machines require more operator involvement. Linear machines are suitable for lower production volumes, and rotary machines are designed for high-speed mass production.

Transition Paragraph:

Let's explore these different types in more detail.

What are the Different Types of Blowing Machines?

leading paragraph:

What kinds of blowing machines are available?

snippet paragraph:

Blowing machines can be classified into several types: 1) Extrusion Blow Molding: For simple shapes. 2) Injection Blow Molding: For precise dimensions. 3) Stretch Blow Molding (PET): For strong, lightweight bottles. 4) Semi-Automatic: Requires manual operation. 5) Fully Automatic: Operates with minimal human intervention.

Blowing Machine Types

| Type | Description |

|---|---|

| Extrusion Blow Molding | Used for producing simple, hollow shapes by extruding a plastic parison and then blowing it into a mold. |

| Injection Blow Molding | Creates precise, complex shapes by first injection molding a preform and then blowing it into the final shape. |

| Stretch Blow Molding | Ideal for PET bottles, involving stretching the preform before blowing to enhance strength and clarity. |

| Semi-Automatic | Requires manual loading and unloading of materials, offering flexibility for smaller production runs. |

| Fully Automatic | Automates the entire process, from preform loading to bottle ejection, for high-volume production. |

What are the Different Types of Plastic Machines?

leading paragraph:

What other kinds of plastic machines exist?

snippet paragraph:

Besides blowing machines, there are: 1) Injection Molding Machines: For solid plastic parts. 2) Extrusion Machines: For continuous profiles. 3) Thermoforming Machines: For shaping plastic sheets. 4) Compression Molding Machines: For high-strength parts.

Types of Plastic Machines

| Type | Description |

|---|---|

| Injection Molding Machines | Used for creating solid plastic parts by injecting molten plastic into a mold cavity. |

| Extrusion Machines | Produces continuous profiles, such as pipes and sheets, by forcing molten plastic through a die. |

| Thermoforming Machines | Shapes plastic sheets into desired forms using heat and vacuum or pressure. |

| Compression Molding | Creates high-strength parts by compressing a plastic compound within a mold cavity under heat and pressure. |

What Machines are Used to Make Plastic Bottles?

leading paragraph:

What equipment is used to make bottles?

snippet paragraph:

The primary machines are: 1) PET Stretch Blow Molding Machines: For PET bottles. 2) Extrusion Blow Molding Machines: For HDPE bottles. 3) Injection Blow Molding Machines: For small, precise bottles. These machines vary in their process and suitability for different materials and bottle types.

Bottle Making Machines

| Machine Type | Description |

|---|---|

| PET Stretch Blow Molding | Specifically designed for manufacturing PET bottles, offering high clarity and strength. |

| Extrusion Blow Molding | Commonly used for producing HDPE bottles, suitable for household and industrial applications. |

| Injection Blow Molding | Ideal for creating small, precisely shaped bottles, often used in the pharmaceutical and cosmetic industries. |

Conclusion

In summary, PET bottle machines come in different types. They are cater to different production needs. From fully automatic to semi-automatic, and linear to rotary. Knowing these differences helps you choose the best machine. The best machine is the one that fits your business needs.

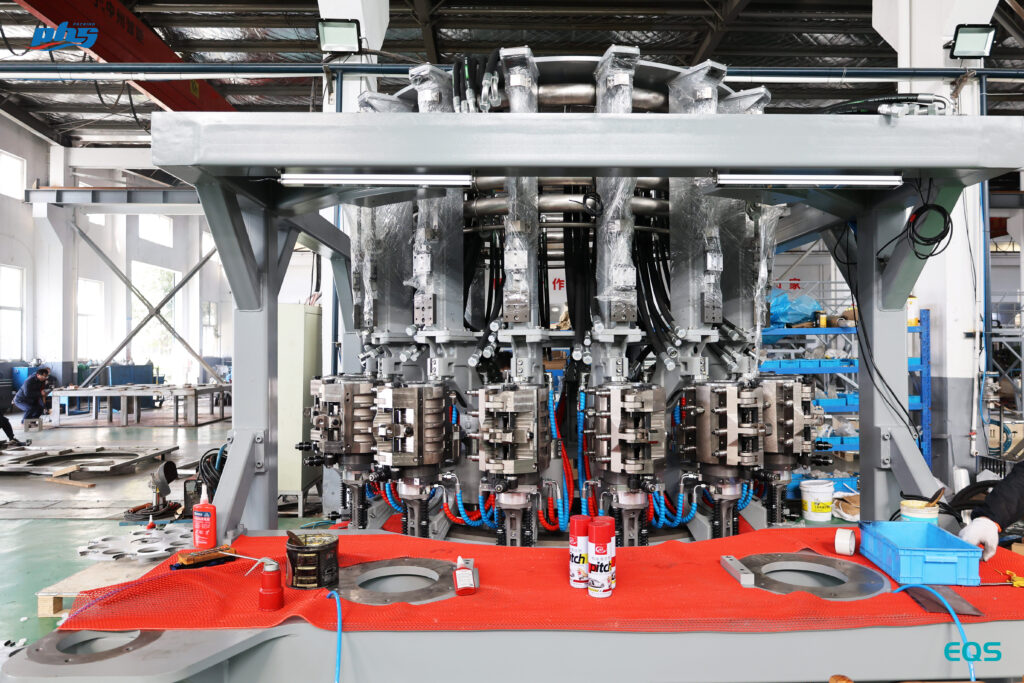

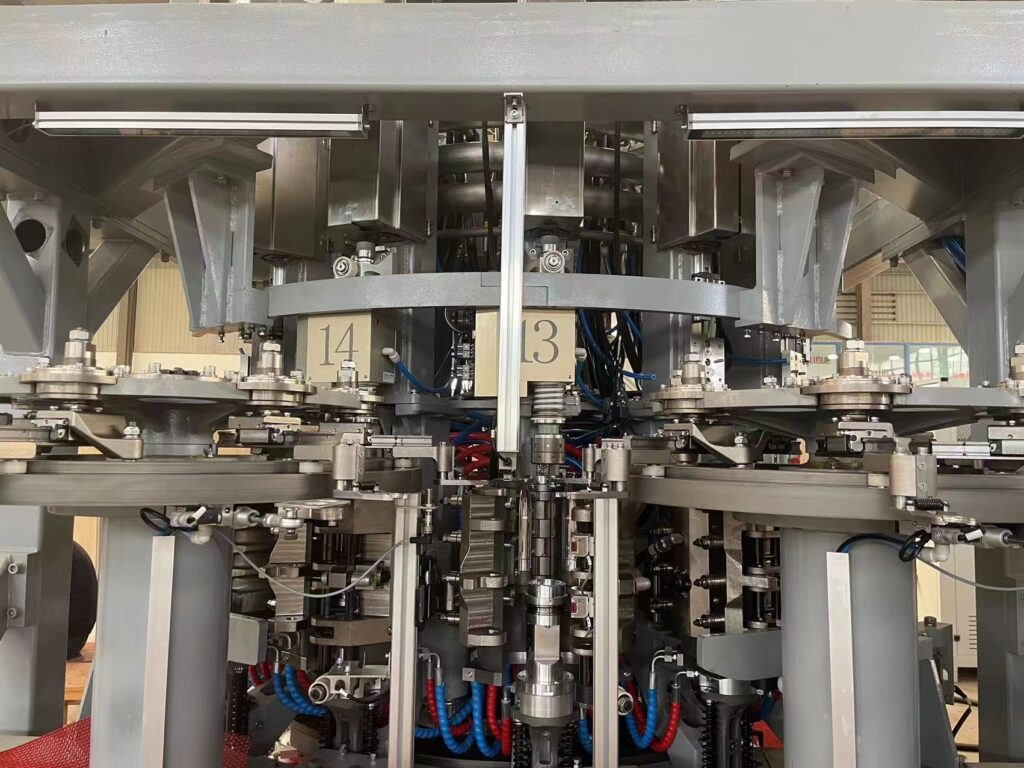

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality bottle blowing machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.