What are the Benefits of a Bottle Blow Molding Machine?

leading paragraph:

Want to produce plastic bottles efficiently and cost-effectively? Blow molding might be the answer.

snippet paragraph:

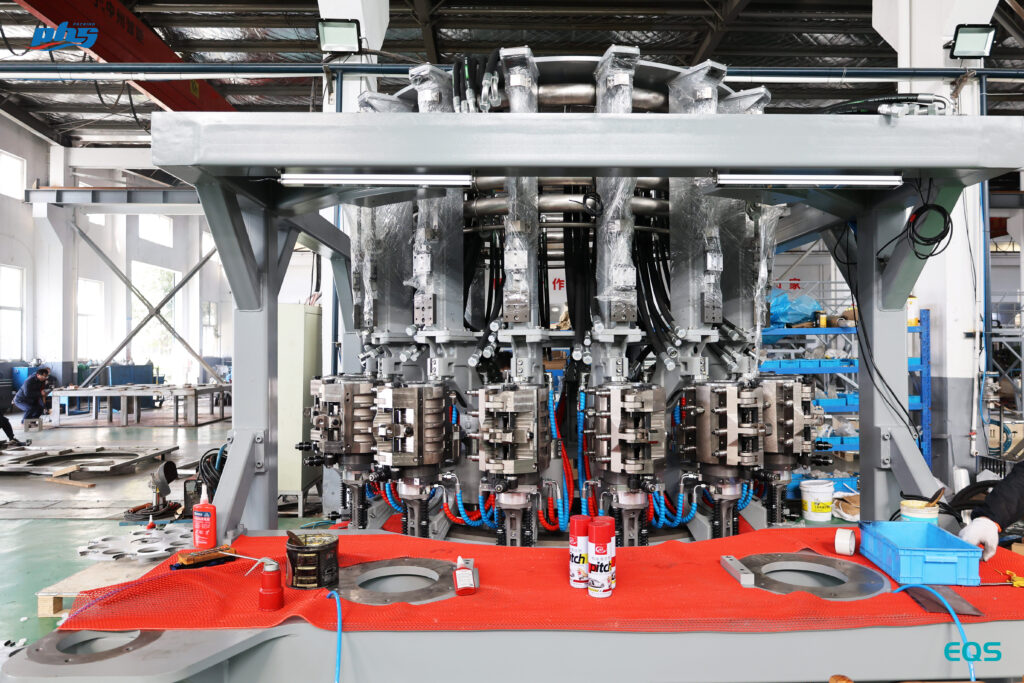

Bottle blow molding machines offer high production speed, cost-effectiveness, design flexibility, and improved quality for plastic containers. They are ideal for mass production of hollow, thin-walled parts like bottles, creating seamless, durable, and customizable products.

Transition Paragraph:

Let's explore why blow molding is so popular for bottle production.

What are the Advantages of Blow Molding?

leading paragraph:

Why should you choose blow molding over other methods?

snippet paragraph:

Blow molding offers several advantages: 1) High Production Speed: Fast cycle times for mass production. 2) Cost-Effectiveness: Lower tooling costs compared to injection molding. 3) Design Flexibility: Ability to create complex shapes and designs. 4) Lightweight Products: Produces thin-walled, lightweight containers. 5) Material Efficiency: Minimal material waste due to the process.

Advantages Breakdown

| Advantage | Description |

|---|---|

| High Production Speed | Faster cycle times mean more parts produced in less time. |

| Cost-Effectiveness | Lower tooling costs make it economical for large production runs. |

| Design Flexibility | Allows for complex shapes and unique designs. |

| Lightweight Products | Creates containers that are lightweight, reducing material usage and transportation costs. |

| Material Efficiency | The process minimizes waste, making it an environmentally friendly option. |

I've noticed that companies using blow molding often see significant cost savings and design innovation.

Why is Blow Molding Used for Bottles?

leading paragraph:

Why is blow molding popular in bottle production?

snippet paragraph:

Blow molding is ideal for bottles because: 1) Hollow Shapes: Easily creates hollow, seamless containers. 2) Thin Walls: Produces lightweight, rigid bottles. 3) High Volume: Efficient for mass production. 4) Uniform Thickness: Ensures consistent wall thickness for structural integrity. 5) Cost-Effective: Economical for large-scale bottle manufacturing.

Reasons for Using Blow Molding

| Reason | Description |

|---|---|

| Hollow Shapes | Naturally suited for creating hollow containers like bottles. |

| Thin Walls | Allows for the production of lightweight yet durable bottles. |

| High Volume | Efficiently produces large quantities, meeting market demands. |

| Uniform Thickness | Ensures bottles have consistent strength and durability. |

| Cost-Effective | Provides an economical solution for mass-producing bottles. |

What is the Use of a Bottle Blowing Machine?

leading paragraph:

What is the specific purpose of this machine?

snippet paragraph:

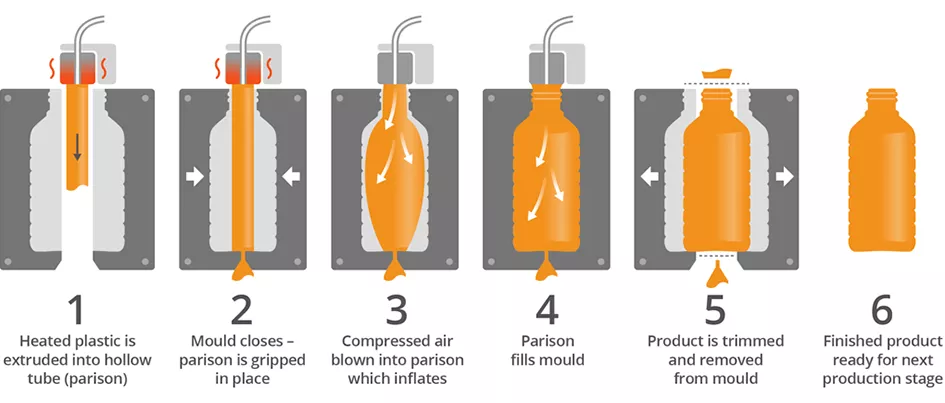

A bottle blowing machine is used to manufacture plastic bottles from plastic materials. The machine heats a plastic preform or parison and inflates it with compressed air inside a mold to create the desired bottle shape. It automates the bottle-making process, ensuring consistent quality and high production rates.

Key Functions

| Function | Description |

|---|---|

| Heating | Heats the plastic preform or parison to the required temperature for molding. |

| Inflation | Uses compressed air to inflate the plastic inside the mold. |

| Molding | Shapes the plastic into the desired bottle form. |

| Cooling | Cools the bottle to maintain its shape. |

| Ejection | Ejects the finished bottle from the mold. |

What is the Purpose of the Molding Machine?

leading paragraph:

What's the general function of a molding machine?

snippet paragraph:

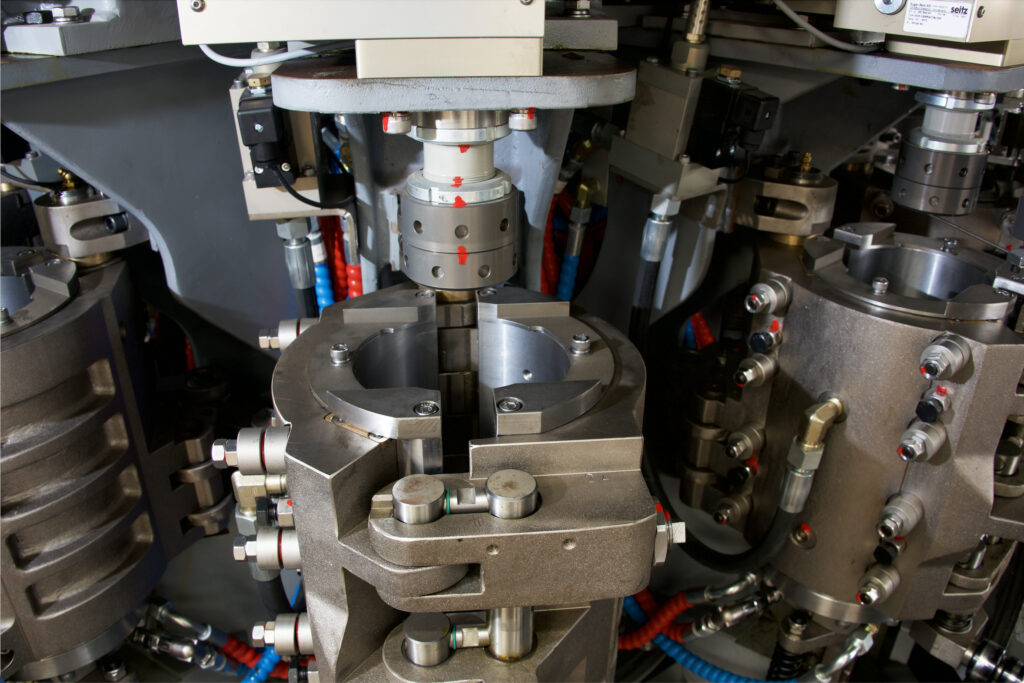

The purpose of a molding machine is to shape raw materials (typically plastics) into desired forms by melting the material and injecting or forming it within a mold cavity. The machine controls the temperature, pressure, and timing to produce consistent and precise parts. Molding machines are used in various industries to manufacture a wide range of products.

Molding Machine Applications

| Application | Description |

|---|---|

| Plastic Products | Manufacturing of plastic bottles, containers, toys, and automotive parts. |

| Rubber Products | Production of rubber tires, seals, and gaskets. |

| Metal Products | Creation of metal castings and components using die-casting techniques. |

Conclusion

Bottle blow molding machines provide numerous benefits. It is very useful for any business that needs to make plastic bottles. These advantages include fast speed, good designs and low costs.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.