Water Treatment: Improve The Purity of The Production Line!!!

leading paragraph:

Want a cleaner, more efficient production line? It starts with water!

snippet paragraph:

Water treatment is essential for improving the purity and efficiency of any production line that uses water. It removes contaminants, minerals, and impurities, ensuring high-quality output, preventing equipment damage, and meeting regulatory standards. Proper water treatment enhances product quality and extends equipment lifespan.

Transition Paragraph:

Let's explore how water treatment can revolutionize your production line, ensuring superior results and operational excellence.

Why Water Treatment Matters: Purity and Efficiency

leading paragraph:

Why treat water? The benefits are clear for your production.

snippet paragraph:

Water treatment removes harmful contaminants, minerals, and impurities from the water used in production. This leads to higher product quality, reduced equipment downtime due to scaling or corrosion, and compliance with industry-specific regulations, resulting in increased efficiency and cost savings.

Key Advantages

- Higher Product Quality: Pure ingredients.

- Reduced Downtime: Preventing equipment issues.

- Regulatory Compliance: Meeting standards.

- Extended Equipment Life: Preventing corrosion.

- Cost Savings: Reducing maintenance.

- Better Customer Satisfaction: Higher quality product

Dive deeper Paragraph:

Water treatment is not just an option; it's a necessity for any production line that relies on water. By removing harmful contaminants and impurities, water treatment ensures higher product quality, reduces equipment downtime, and helps companies meet regulatory standards.

Higher Product Quality

The purity of the water used in production directly impacts the quality of the final product. Contaminants in the water can alter the taste, color, or stability of the product, leading to inconsistencies and customer dissatisfaction. Water treatment removes these contaminants, ensuring that the product is consistent, high-quality, and meets customer expectations.

Reduced Downtime

Untreated water can cause scaling and corrosion in equipment, leading to frequent breakdowns and costly downtime. Water treatment removes the minerals and other substances that cause scaling and corrosion, extending the life of the equipment and reducing the need for repairs.

Regulatory Compliance

Many industries, such as food and beverage, pharmaceuticals, and electronics, have strict regulations regarding the quality of water used in production. Water treatment helps companies meet these regulations, avoiding fines and other penalties.

Common Water Treatment Technologies: Choosing the Right Fit

leading paragraph:

What are the best ways to treat water? Options abound.

snippet paragraph:

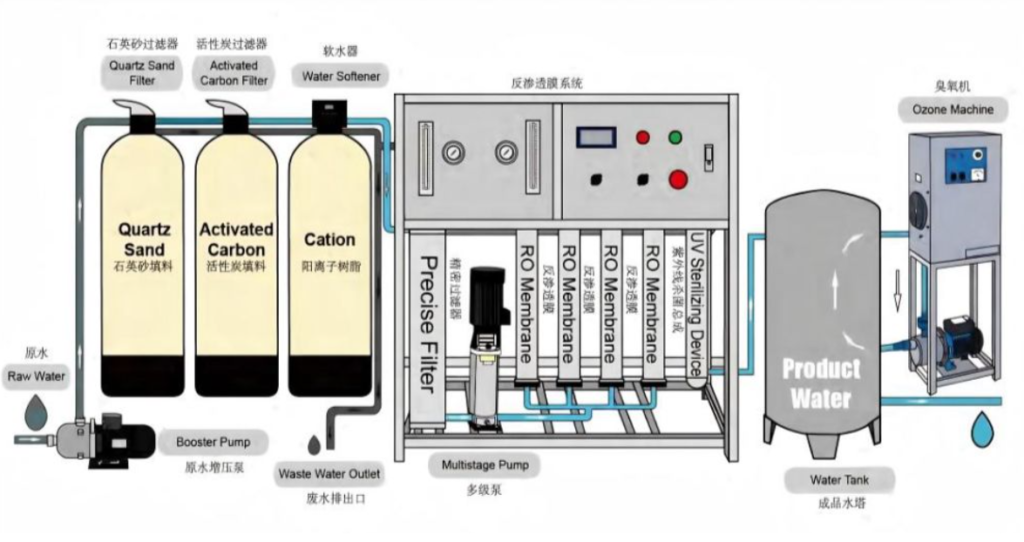

Common water treatment technologies include filtration, reverse osmosis (RO), UV sterilization, and chemical treatment. Filtration removes particulate matter, RO removes dissolved solids, UV sterilization eliminates microorganisms, and chemical treatment adjusts pH levels and disinfects the water. The best technology depends on specific water quality needs.

Treatment Options

- Filtration: Removing particles.

- Reverse Osmosis (RO): Removing dissolved solids.

- UV Sterilization: Killing microorganisms.

- Chemical Treatment: Adjusting pH.

- Deionization (DI): Removing ions.

- Water Softening: Removing hardness.

Dive deeper Paragraph:

Choosing the right water treatment technology is essential to achieving the desired level of purity and efficiency in your production line. The best technology will depend on the specific contaminants present in the water, the desired level of purity, and the budget constraints.

Filtration

Filtration is a basic water treatment technology that removes particulate matter, such as sand, silt, and rust, from the water. Filters come in a variety of sizes and materials, and can be used to remove particles as small as 0.1 microns.

Reverse Osmosis (RO)

Reverse osmosis (RO) is a more advanced water treatment technology that removes dissolved solids, such as salts, minerals, and organic compounds, from the water. RO works by forcing water through a semi-permeable membrane, which blocks the passage of dissolved solids.

UV Sterilization

UV sterilization is a water treatment technology that kills microorganisms, such as bacteria, viruses, and protozoa, using ultraviolet (UV) light. UV sterilization is a chemical-free method of disinfection that does not alter the taste or odor of the water.

Implementing Water Treatment: A Step-by-Step Approach

leading paragraph:

How do you add water treatment to your line? Here's a plan.

snippet paragraph:

Implementing water treatment involves assessing water quality, selecting appropriate technologies, installing equipment, and maintaining the system. Regular testing ensures optimal performance. Consulting with water treatment specialists helps tailor the system to specific production line requirements and ensures long-term efficiency.

Implementation Steps

- Assess Water Quality: Identify contaminants.

- Select Technology: Choose appropriate methods.

- Install Equipment: Set up the system.

- Maintain System: Ensure proper function.

- Regular Testing: Monitor water purity.

- Expert Consultations: Tailor the system for best results

Dive deeper Paragraph:

Implementing water treatment in your production line requires a systematic approach that takes into account the specific needs of your operation. By following a step-by-step process, you can ensure that the water treatment system is properly designed, installed, and maintained.

Assess Water Quality

The first step is to assess the quality of the water being used in the production line. This involves testing the water for a variety of contaminants, such as bacteria, minerals, and organic compounds. The results of the water quality assessment will help you determine the appropriate water treatment technologies to use.

Select Technology

Based on the water quality assessment, you can select the appropriate water treatment technologies for your production line. This may involve using a combination of technologies, such as filtration, reverse osmosis, and UV sterilization.

Install Equipment

Once you have selected the appropriate water treatment technologies, you can install the equipment. This may involve working with a qualified contractor to install the plumbing, electrical, and other necessary components.

Case Studies: Success Stories in Water Treatment

leading paragraph:

How has water treatment helped others? Real-world examples.

snippet paragraph:

Numerous industries have benefited from water treatment. Food and beverage companies achieve consistent product quality, pharmaceutical firms ensure purity for drug manufacturing, and electronics manufacturers prevent defects in semiconductor production. These case studies highlight the transformative impact of water treatment on production line outcomes.

Industry Examples

- Food and Beverage: Consistent quality.

- Pharmaceutical: Purity for drugs.

- Electronics: Preventing defects.

- Cosmetics: Maintaining formula integrity

- Power Generation: Improving performance

- Agriculture: Improving irrigation

Dive deeper Paragraph:

Water treatment has been successfully implemented in a wide range of industries, demonstrating its versatility and effectiveness in improving production line outcomes.

Food and Beverage

In the food and beverage industry, water treatment is used to ensure consistent product quality, prevent contamination, and meet regulatory standards. For example, a bottled water company may use reverse osmosis to remove minerals and other impurities from the water, ensuring that the bottled water is pure and refreshing.

Pharmaceutical

In the pharmaceutical industry, water treatment is used to ensure the purity of water used in drug manufacturing. Contaminants in the water can affect the efficacy and safety of the drugs, so it is essential to use highly purified water.

Conclusion

Water treatment is key to a pure, efficient production line. By removing impurities, you improve product quality, protect equipment, and meet regulations!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.