Turnkey project: one-stop solution

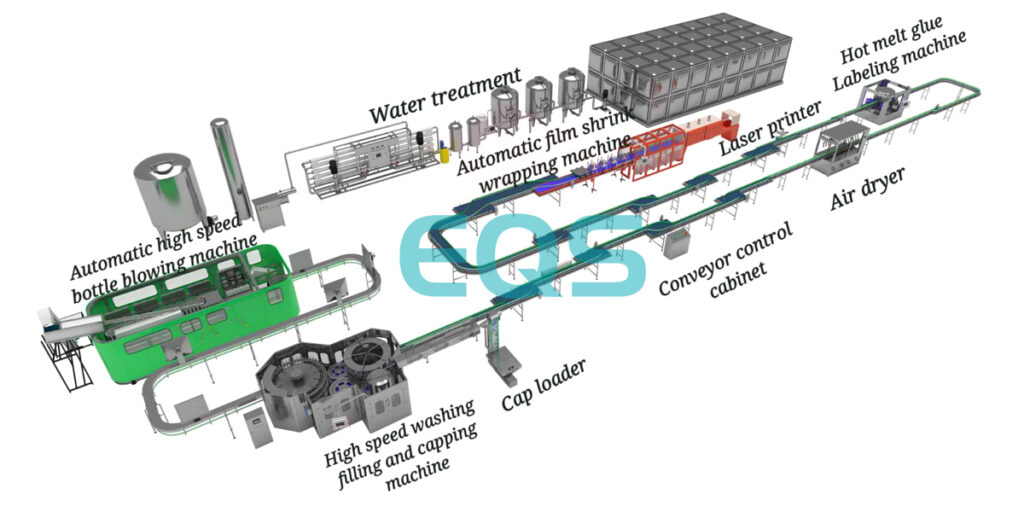

In the liquid filling machinery industry, turnkey projects have become a popular service model, especially for small to large beverage producers who want to quickly start their production lines. Turnkey engineering is a one-stop solution, where customers only need to provide the factory building, and all other production equipment related work such as design, procurement, installation, and commissioning is the responsibility of the service provider.

The significant advantage of this model is that customers can minimize their direct involvement in the complexity of equipment installation and debugging. Due to various factors affecting the installation and commissioning cycle of liquid canning equipment production lines, including equipment complexity, installation environment, personnel cooperation, etc., turnkey projects can effectively manage these variables and save customers time and energy. For example, the installation and debugging cycle of a fully automated intelligent liquid canning production line may take up to 20-30 days, and a professional team for turnkey projects can ensure the efficient progress of this process, thereby shortening the overall cycle.

For small and medium-sized enterprises, they may lack internal engineering teams or complete production line construction experience, and turnkey projects happen to provide the professional support they need. For large enterprises, turnkey projects can also help them quickly and efficiently complete projects when upgrading existing production lines or expanding into new markets.

The challenge of self purchasing equipment and the charm of turnkey projects

Self purchased equipment will face many challenges in the implementation process, especially for beverage manufacturers who do not have a professional engineering background. Firstly, the installation and debugging cycle of the equipment itself is relatively long, especially for fully automatic intelligent liquid canning production lines, which involve not only the installation of a single device, but also the precise docking and linkage debugging of multiple functional modules. This not only requires a lot of time, but also a professional technical team to complete.

In addition, when purchasing equipment, customers need to solve all possible problems that may arise during the installation process, including but not limited to factory layout, infrastructure matching, technical personnel allocation, etc. The resolution of these issues often requires additional time and resources, thereby prolonging the production cycle of the equipment. In some special cases, if the factory conditions do not meet the equipment installation requirements, it may be necessary to carry out factory renovation, which will undoubtedly further increase costs and time.

On the other hand, turnkey projects are favored by customers due to their obvious comparative advantages. A professional team not only provides equipment, but also is responsible for installation and debugging to ensure that the equipment can be quickly put into use. The services of turnkey projects usually include early-stage consulting and design, mid-term equipment supply and installation, as well as later stage debugging, training, etc. This one-stop solution greatly simplifies customer engagement, allowing them to invest more energy into product production and marketing.

Key points for implementing turnkey projects

Although implementing a turnkey project can bring many benefits, the key to success lies in the implementation of several important precautions. Firstly, choosing an experienced and reputable supplier is crucial. A professional supplier can not only provide high-quality equipment, but more importantly, provide professional installation and commissioning services to ensure that projects are completed on time.

Communication and cooperation between customers and suppliers are also indispensable. At various stages of the project, both parties need to maintain close communication, resolve issues in a timely manner, and avoid misunderstandings and delays. For example, suppliers need to understand the specific needs and factory conditions of customers in order to design suitable installation plans. At the same time, customers also need to provide necessary support and information in a timely manner to cooperate with suppliers' work.

Before signing the contract, both parties should discuss and clarify the scope, timeline, budget, and responsibilities and obligations of the project in detail. In addition, the contract should also include provisions on important matters such as force majeure, legal liability for breach of contract, and dispute resolution procedures to protect the rights and interests of both parties.

Risk management cannot be ignored during project execution. Suppliers should have the ability to predict and avoid potential risks, such as material price increases, technical errors, etc., while customers need to have a clear understanding of demand changes to avoid incurring additional costs. In short, through meticulous planning and joint efforts of both parties, turnkey projects can effectively reduce risks and improve success rates.

The benefits of turnkey projects: rapid production and market response

The benefits of turnkey projects in shortening production time are particularly significant. Through the one-stop service of a professional team, the entire process from design to installation and debugging has been optimized, avoiding delays and problems that may occur during the traditional self purchased equipment process. For example, purchasing a fully automated intelligent liquid canning production line may require a 20-30 day installation and debugging cycle, while a turnkey project can significantly shorten this time through professional management and technical support, enabling the production line to be put into use as soon as possible.

Rapid production not only means a quick return of funds, but also means that enterprises can respond to market and customer demands more quickly. In the fiercely competitive beverage market, seizing market opportunities is crucial. The turnkey project enables enterprises to quickly launch new products, meet market changes, and enhance customer satisfaction.

In terms of economic benefits, turnkey projects can help businesses save time, costs, and management energy. Customers do not need to invest a lot of resources in managing the details of equipment procurement, installation, and commissioning processes, but can focus their energy on core businesses such as product development and marketing. In addition, as turnkey projects typically use fixed price contracts, customers can clearly define their budget at the beginning of the project, thereby effectively controlling costs.

In summary, turnkey projects have brought significant economic benefits to enterprises by shortening production time, responding quickly to market demand, and saving costs.

Turnkey project: a wise choice for efficient production

In the liquid filling machinery industry, turnkey projects have proven to be an efficient and reliable service model, especially for beverage manufacturers who want to quickly start their production lines. It can not only significantly shorten the production time, reduce the initial investment and risk of enterprises, but also enable enterprises to quickly respond to market changes and enhance competitiveness.

The key to the success of a turnkey project lies in selecting experienced suppliers and close cooperation between both parties. Effective communication and collaboration can ensure that projects are completed on time and with quality. In addition, case analysis shows that turnkey projects not only bring economic benefits, but also enhance customer satisfaction and establish long-term cooperation.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.