The Science Behind Perfect Carbonation in Can Filling Machines

leading paragraph:

Ever wonder how that perfect fizz gets into your canned soda or sparkling water? It's all about science!

snippet paragraph:

Achieving perfect carbonation in Can Filling Machines involves precise control of temperature, pressure, and gas solubility. By understanding these scientific principles, manufacturers can ensure consistent and optimal carbonation levels in every can, enhancing the beverage's taste and appeal.

Transition Paragraph:

Let's dive into the scientific details that make this process possible.

Understanding Gas Solubility

leading paragraph:

Why does some soda have more fizz than others?

snippet paragraph:

Gas solubility, the amount of gas that can dissolve in a liquid, is influenced by temperature and pressure. Lower temperatures and higher pressures increase the solubility of carbon dioxide (CO2) in beverages, leading to higher carbonation levels.

Factors Affecting Gas Solubility

- Temperature: Lower temperatures allow more CO2 to dissolve in the liquid.

- Pressure: Higher pressures force more CO2 to dissolve in the liquid.

- Type of Gas: CO2 is commonly used due to its non-toxic and readily soluble nature.

- Liquid Composition: The presence of other substances can affect CO2 solubility.

- Henry's Law: Describes the quantitative relationship between gas pressure and solubility.

Dive deeper Paragraph:

Gas solubility is a crucial factor in achieving perfect carbonation. The amount of gas that can dissolve in a liquid is directly related to temperature and pressure. Lower temperatures allow more carbon dioxide (CO2) to dissolve, as the gas molecules have less kinetic energy and are more easily captured by the liquid. Conversely, higher pressures force more CO2 to dissolve, as the increased pressure pushes the gas molecules into the liquid. The type of gas also matters, with CO2 being the most common choice due to its non-toxic nature and high solubility in water. The composition of the liquid, including the presence of sugars, acids, and other substances, can also affect CO2 solubility. Henry's Law provides a quantitative relationship between gas pressure and solubility, stating that the amount of dissolved gas in a liquid is proportional to its partial pressure above the liquid.

The Role of Temperature Control

leading paragraph:

Why are beverages chilled before carbonation?

snippet paragraph:

Maintaining low temperatures during the carbonation process is essential. We often use cooler to chill the beverage to near-freezing temperatures(0-4°), maximizing CO2 solubility and preventing loss of carbonation.

Dive deeper Paragraph:

Temperature control is paramount in the carbonation process. Use cooler to ensure that the beverage is chilled to near-freezing temperatures. During the beverage blending and mixing process, the chiller cools the materials to ensure that they are mixed and filled at the optimal temperature, thereby improving production efficiency and product quality. Low temperature environment helps dissolve carbon dioxide, making the gas content of beverages more ideal.

Pressure Management Techniques

leading paragraph:

How does pressure affect the fizz in canned drinks?

snippet paragraph:

Precise pressure management is crucial. Can Filling Machines use pressure regulators and relief valves to maintain a consistent high-pressure environment. This ensures that CO2 remains dissolved in the liquid during filling and prevents excessive foaming or loss of carbonation.

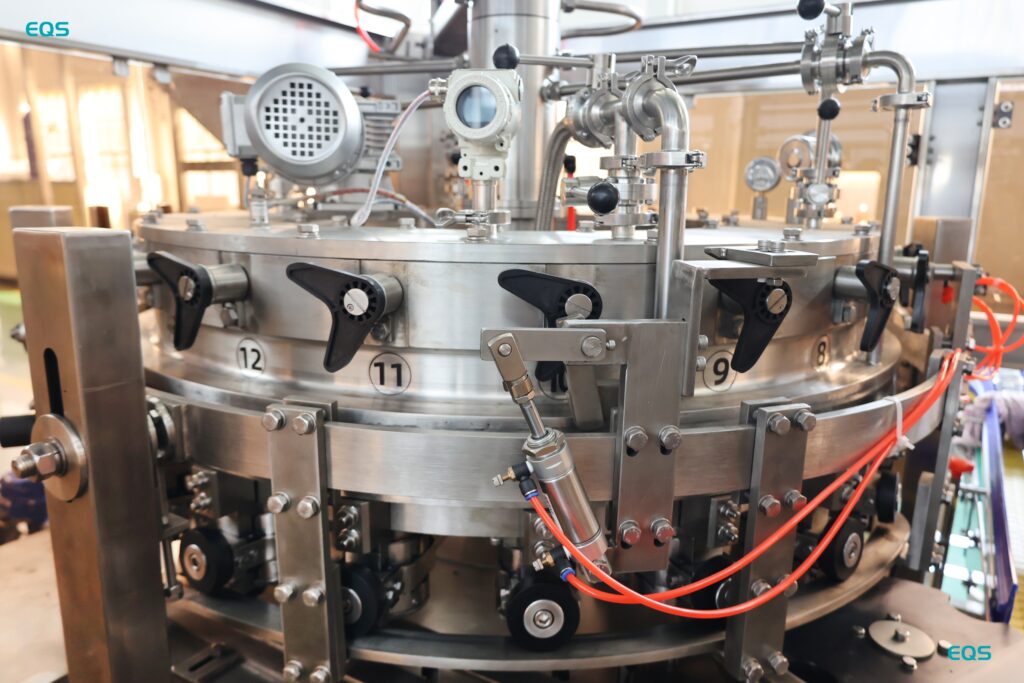

Components for Pressure Control

- Pressure Regulators: Maintain a constant pressure in the filling tank.

- Relief Valves: Prevent over-pressurization and potential equipment damage.

- Pressure Sensors: Monitor the pressure and provide feedback for adjustments.

- Sealed Filling Heads: Prevent gas leakage during the filling process.

- Counter Pressure Filling: Balancing the pressure in the can with the pressure in the filling tank

Dive deeper Paragraph:

Pressure management is another critical aspect of achieving perfect carbonation. Can filling machines use a variety of components to maintain a consistent high-pressure environment, ensuring that CO2 remains dissolved in the liquid during filling and preventing excessive foaming or loss of carbonation. Pressure regulators maintain a constant pressure in the filling tank, compensating for fluctuations in gas supply or demand. Relief valves prevent over-pressurization and potential equipment damage by releasing excess pressure. Pressure sensors monitor the pressure and provide feedback for adjustments, ensuring that the pressure remains within the desired range. Sealed filling heads prevent gas leakage during the filling process, minimizing the loss of carbonation. Counter pressure filling balances the pressure in the can with the pressure in the filling tank, allowing for a smooth and controlled filling process.

Filling Techniques for Optimal Carbonation Retention

leading paragraph:

How do filling techniques preserve that precious fizz?

snippet paragraph:

Specific filling techniques minimize CO2 loss. Counter-pressure filling, where the can is pre-pressurized with CO2 before filling, reduces foaming and ensures consistent carbonation. Gentle filling methods also minimize agitation, which can cause CO2 to escape.

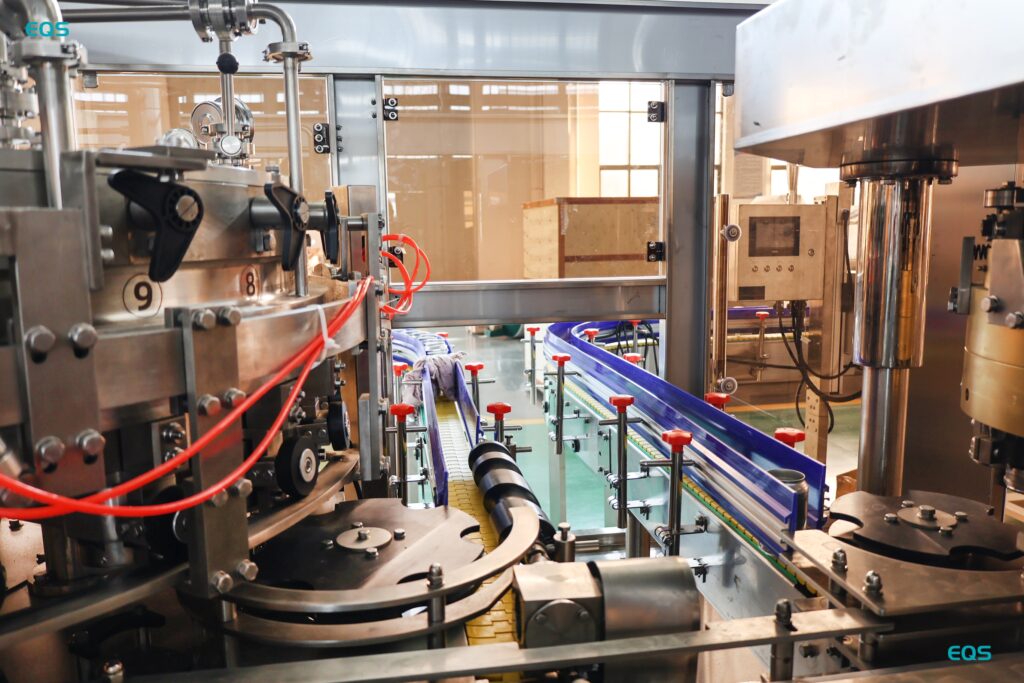

Filling Methods for Carbonation Retention

- Counter-Pressure Filling: Pre-pressurizes the can with CO2.

- Gentle Filling: Minimizes agitation to prevent CO2 release.

- Bottom-Up Filling: Reduces foaming by minimizing turbulence.

- Controlled Flow Rates: Prevents excessive splashing and CO2 loss.

- Hygienic Design: Minimizing the risk of contamination.

Dive deeper Paragraph:

The filling technique employed by can filling machines plays a significant role in retaining carbonation. Counter-pressure filling is a common method that pre-pressurizes the can with CO2 before filling, creating an equilibrium that minimizes foaming and ensures consistent carbonation levels. Gentle filling methods reduce agitation, which can cause CO2 to escape from the liquid. Bottom-up filling minimizes turbulence by introducing the beverage from the bottom of the can, reducing foaming. Controlled flow rates prevent excessive splashing and CO2 loss during the filling process. And hygienic design minimizes the risk of contamination, ensuring that the beverage remains pure and stable.

The Importance of Equipment Maintenance

leading paragraph:

Can a well-maintained machine improve carbonation?

snippet paragraph:

Regular maintenance of can filling machines is crucial. Leaks, faulty regulators, or malfunctioning cooling systems can lead to inconsistent carbonation. Scheduled inspections and timely repairs ensure the machine operates at peak efficiency, delivering consistently carbonated beverages.

Maintenance Checklist for Can Filling Machines

- Check for Leaks: Inspect all connections and seals for leaks.

- Inspect Regulators: Ensure pressure regulators are functioning correctly.

- Verify Cooling System: Check the cooling system's performance and coolant levels.

- Calibrate Sensors: Ensure accurate readings from pressure and temperature sensors.

- Clean Filling Heads: Prevent contamination and ensure proper sealing.

Dive deeper Paragraph:

Proper maintenance is essential for ensuring the consistent performance of can filling machines. Leaks in the system can lead to a loss of pressure and carbonation. Faulty regulators can cause inconsistent pressure levels, resulting in under- or over-carbonated beverages. Malfunctioning cooling systems can lead to higher temperatures, reducing CO2 solubility and causing a loss of carbonation. Scheduled inspections and timely repairs can prevent these issues, ensuring that the machine operates at peak efficiency. Regularly checking for leaks, inspecting regulators, verifying the cooling system's performance, calibrating sensors, and cleaning filling heads can all contribute to maintaining optimal carbonation levels.

Conclusion

Achieving perfect carbonation in Can Filling Machines is a science that requires careful control of temperature, pressure, and filling techniques. By understanding and applying these principles, manufacturers can consistently deliver the fizzy beverages that consumers love.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.