Some Burning Questions You May Have About Water Filling Machines

leading paragraph:

Curious about water filling machines? Let’s clear up the confusion!

snippet paragraph:

Water filling machines are essential for bottling water efficiently and safely. They come in various types, from manual to fully automated, and are designed to handle different bottle sizes and production volumes. Understanding these machines can help you choose the right one for your business.

Transition Paragraph:

Let's dive into some common questions about water filling machines.

What are the different types of water filling machines?

leading paragraph:

So many machines, which one to pick?

snippet paragraph:

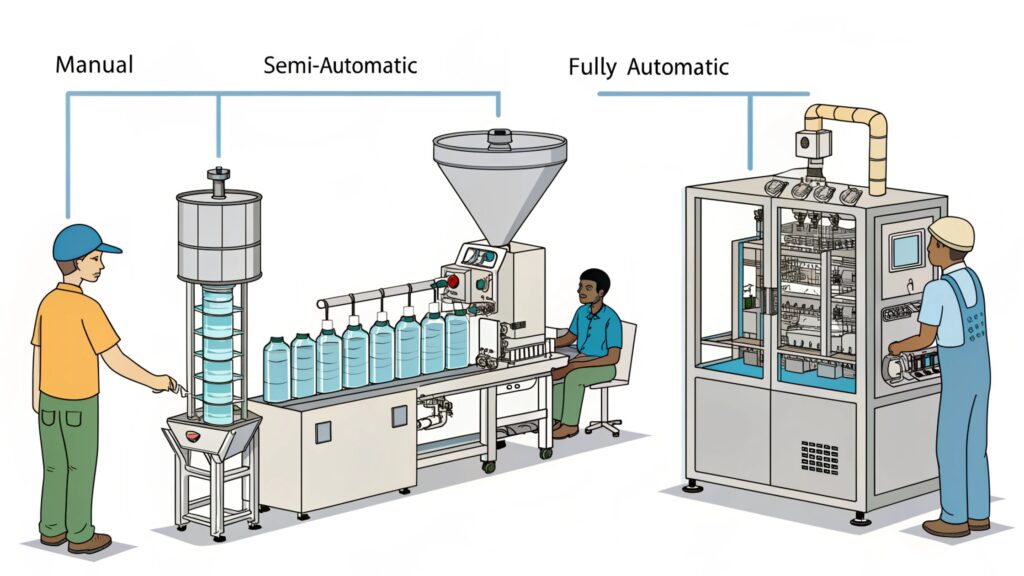

Water filling machines come in several types, including manual, semi-automatic, and fully automatic. Manual machines are for small-scale operations, semi-automatic offer a balance of automation and manual input, and fully automatic machines are for high-volume production with minimal human intervention. Each type suits different production needs and budgets.

Types of Filling Machines

- Manual: Small-scale, hands-on.

- Semi-Automatic: Some automation.

- Fully Automatic: High-volume, minimal labor.

- Rotary Filling Machine: High speed filling for big companies

- Inline Filling Machine: Flexible filling for different bottle types

Dive deeper Paragraph:

Water filling machines are available in a range of types, each designed to cater to different production volumes, budgets, and operational requirements. Understanding the characteristics of each type can help you make an informed decision when selecting a machine for your business.

Manual Filling Machines

Manual filling machines are the simplest and most affordable type of water filling machine. They require manual operation for each filling cycle, making them suitable for small-scale operations with low production volumes.

Semi-Automatic Filling Machines

Semi-automatic filling machines offer a balance between automation and manual input. They automate certain tasks, such as filling and capping, while still requiring manual intervention for other processes, such as bottle placement and removal.

How do water filling machines ensure hygiene?

leading paragraph:

Keeping water clean during filling is a must!

snippet paragraph:

Water filling machines ensure hygiene through stainless steel construction, easy-to-clean designs, and sanitary components. Many machines incorporate Clean-In-Place (CIP) systems for automated cleaning and sterilization. Regular maintenance and strict cleaning protocols are essential to prevent contamination and maintain water purity.

Hygiene Features

- Stainless Steel: Prevents corrosion.

- Easy-to-Clean: Accessible parts.

- CIP Systems: Automated cleaning.

- Air Filters: Prevents airborne contaminants from entering the filling area

- UV Sterilization: Water source is sterilized before filling

Dive deeper Paragraph:

Maintaining hygiene is of paramount importance in water filling operations to prevent contamination and ensure the safety of the bottled water. Water filling machines incorporate several features and protocols to achieve this goal.

Stainless Steel Construction

Stainless steel is the preferred material for water filling machines due to its durability, corrosion resistance, and ease of cleaning. Stainless steel surfaces are non-porous and do not harbor bacteria, making them ideal for food contact applications.

Easy-to-Clean Design

Water filling machines are designed with smooth surfaces, rounded corners, and minimal crevices to facilitate easy cleaning and prevent the accumulation of bacteria. All components that come into contact with water are readily accessible for cleaning and sterilization.

What bottle types can water filling machines handle?

leading paragraph:

Got different bottles? No problem for these machines!

snippet paragraph:

Water filling machines can handle various bottle types, including PET, glass, and HDPE. Machines are designed to accommodate different bottle shapes and sizes. Adjustable settings and specialized components ensure efficient filling without damage. Some machines can switch between bottle types with minor adjustments.

Bottle Compatibility

- PET Bottles: Common and lightweight.

- Glass Bottles: Require gentle handling.

- HDPE Bottles: Durable and versatile.

- Bottle Sizes: Different machines for different size ranges

- Bottle Shapes: Round, square, or custom shapes

Dive deeper Paragraph:

Water filling machines are designed to accommodate a wide range of bottle types, ensuring compatibility with various packaging materials and shapes. The choice of bottle type can impact the design and functionality of the filling machine.

PET Bottles

PET (Polyethylene Terephthalate) bottles are a popular choice for bottled water due to their lightweight, durability, and recyclability. Water filling machines for PET bottles are designed to handle the bottles gently to prevent deformation or damage.

Glass Bottles

Glass bottles offer a premium look and feel, but they require more careful handling than PET bottles. Water filling machines for glass bottles are equipped with features such as cushioned conveyors and soft grippers to prevent breakage.

How to maintain a water filling machine?

leading paragraph:

Keep your machine running smoothly!

snippet paragraph:

Maintaining a water filling machine involves regular cleaning, lubrication, and inspection. Follow the manufacturer's guidelines for maintenance schedules. Regularly check and replace worn parts, such as seals and nozzles. Proper maintenance ensures optimal performance, prolongs the machine's lifespan, and prevents costly breakdowns.

Maintenance Tips

- Regular Cleaning: Prevent buildup.

- Lubrication: Keep parts moving smoothly.

- Inspection: Check for wear and tear.

- Parts Replacement: Replace worn parts.

- Follow the Manual: Adhere to manufacturer guidelines

Dive deeper Paragraph:

Proper maintenance is essential for ensuring the reliable and efficient operation of a water filling machine. Regular maintenance helps prevent breakdowns, prolongs the machine's lifespan, and ensures consistent water quality.

Regular Cleaning

Regular cleaning is crucial for preventing the buildup of bacteria, mold, and other contaminants within the water filling machine. All parts that come into contact with water should be cleaned and sanitized regularly using appropriate cleaning agents.

Lubrication

Lubrication is necessary to keep moving parts operating smoothly and prevent wear and tear. Follow the manufacturer's recommendations for the type and frequency of lubrication.

Conclusion

Water filling machines can be confusing, but understanding the basics helps. Pick the right one and keep it clean for the best results!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.