Production Process of Soda Water: From Fizz to Finish

leading paragraph:

Ever wonder how soda water gets its fizz? Let's take a look!

snippet paragraph:

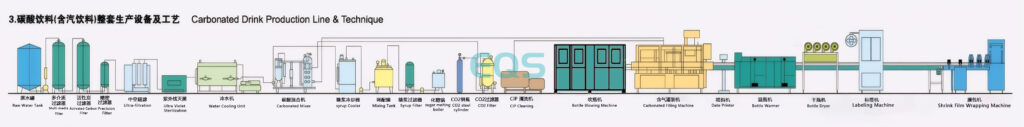

The production process of soda water involves several key steps: water purification, carbonation, mixing (if flavored), and bottling. Each step is crucial to ensure the quality, safety, and refreshing taste of the final product. Understanding this process helps appreciate the science behind your bubbly drink.

Transition Paragraph:

Let's dive into the details of how soda water is made, step by step.

Water Purification: The Foundation of Quality

leading paragraph:

Clean water is key to great soda!

snippet paragraph:

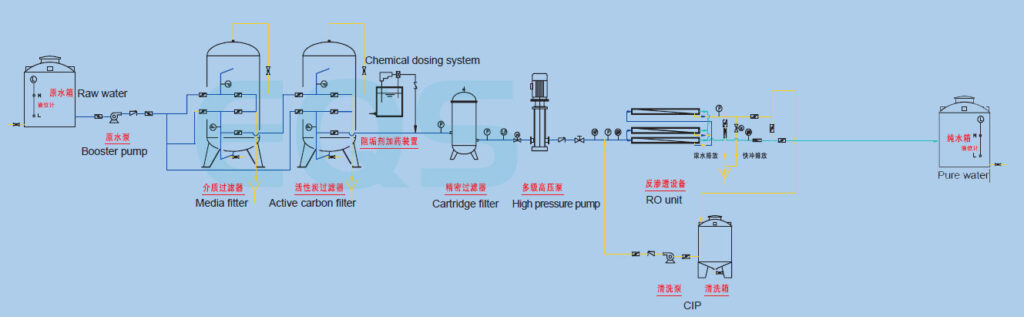

The first step in soda water production is water purification. This process removes impurities, minerals, and contaminants to ensure the water is clean and safe for consumption. Common purification methods include filtration, reverse osmosis, and UV sterilization, which guarantee a pure and refreshing base for the soda water.

Purification Methods

- Filtration: Removes particles and sediment.

- Reverse Osmosis: Eliminates dissolved solids.

- UV Sterilization: Kills bacteria and microorganisms.

- Activated Carbon Filtration: Removes chlorine and organic compounds

- Deionization: Removes ions for ultimate purity

Dive deeper Paragraph:

Water purification is a critical step in the production of soda water, ensuring that the final product is safe, clean, and refreshing. This process involves removing impurities, minerals, and contaminants from the water source using a variety of methods.

Filtration

Filtration is a common method used to remove particles and sediment from the water. This process typically involves passing the water through a series of filters with progressively smaller pore sizes, trapping any solid particles that may be present.

Reverse Osmosis

Reverse osmosis is a more advanced purification method that eliminates dissolved solids, such as salts and minerals, from the water. This process involves forcing the water through a semi-permeable membrane that blocks the passage of dissolved solids while allowing pure water to pass through.

Carbonation: Adding the Fizz

leading paragraph:

Bubbles make it fun! Here's how they're added.

snippet paragraph:

Carbonation is the process of dissolving carbon dioxide gas in the purified water. This is typically done under high pressure and low temperature to maximize the amount of CO2 that can be dissolved. The result is soda water with its characteristic fizz and effervescence.

Carbonation Techniques

- High Pressure: Increases CO2 solubility.

- Low Temperature: Enhances CO2 absorption.

- Direct Injection: Injects CO2 directly into the water.

- Counter Pressure Filling: Prevents loss of carbonation during filling

- Carbonation Stones: Creates fine bubbles for better integration

Dive deeper Paragraph:

Carbonation is the key step that transforms purified water into soda water, giving it its characteristic fizz and effervescence. This process involves dissolving carbon dioxide gas in the water under specific conditions.

High Pressure

Increasing the pressure of the carbon dioxide gas increases its solubility in water. This means that more CO2 can be dissolved in the water at higher pressures, resulting in a more highly carbonated product.

Low Temperature

Lowering the temperature of the water also enhances the absorption of CO2. Cold water can hold more dissolved gas than warm water, so the carbonation process is typically carried out at low temperatures to maximize the amount of CO2 that can be dissolved.

Mixing (If Flavored): Enhancing the Taste

leading paragraph:

Want some flavor? This is where it happens!

snippet paragraph:

If the soda water is flavored, the next step is mixing. Flavorings, such as natural extracts or artificial flavors, are carefully blended into the carbonated water. This process ensures a consistent and appealing taste. The mixing process is closely monitored to maintain quality and flavor consistency.

Flavoring Methods

- Natural Extracts: Derived from fruits and plants.

- Artificial Flavors: Synthetic flavor compounds.

- Precise Measurements: Ensures consistent taste.

- Agitation: Ensures uniform mixing

- Quality Control: Regular taste testing

Dive deeper Paragraph:

For flavored soda water, the mixing process is crucial for enhancing the taste and creating a consistent flavor profile. This step involves carefully blending flavorings into the carbonated water.

Natural Extracts

Natural extracts are derived from fruits, plants, and other natural sources. These extracts provide a more authentic and natural flavor to the soda water.

Artificial Flavors

Artificial flavors are synthetic flavor compounds that are designed to mimic the taste of natural flavors. These flavors are often used to create unique and exotic flavor combinations.

Bottling: Sealing the Fizz

leading paragraph:

Last step: getting it into the bottle!

snippet paragraph:

The final step is bottling the soda water. The carbonated or flavored water is filled into sterilized bottles or cans, which are then sealed to prevent the loss of carbonation. The bottles are labeled and packaged for distribution. Efficient bottling processes ensure the soda water retains its fizz and freshness.

Bottling Techniques

- Sterilized Bottles: Prevents contamination.

- Airtight Seals: Maintains carbonation.

- High-Speed Filling: Ensures efficiency.

- Automated Inspection: Checks for defects

- Proper Labeling: Provides product information

Dive deeper Paragraph:

Bottling is the final stage of the soda water production process, where the carbonated or flavored water is filled into sterilized bottles or cans, sealed, labeled, and packaged for distribution.

Sterilized Bottles

Sterilized bottles are used to prevent contamination and ensure the safety of the soda water. The bottles are typically washed and sanitized before being filled with the carbonated water.

Airtight Seals

Airtight seals are essential for maintaining the carbonation of the soda water. These seals prevent the loss of carbon dioxide gas, keeping the soda water fizzy and refreshing.

Conclusion

Soda water production is a detailed process. Clean water, bubbles, flavors, and bottling – all work together for that refreshing taste!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.