Labeling Machine

The bottle labeling machine is widely used in the following industries, such as daily chemicals, food and drinks, medicine, electronic machinery,etc, we focus on the development, design, manufacturing, for sales and maintenance services of all kinds of bottle labeling machines and bottle packing machine equipment

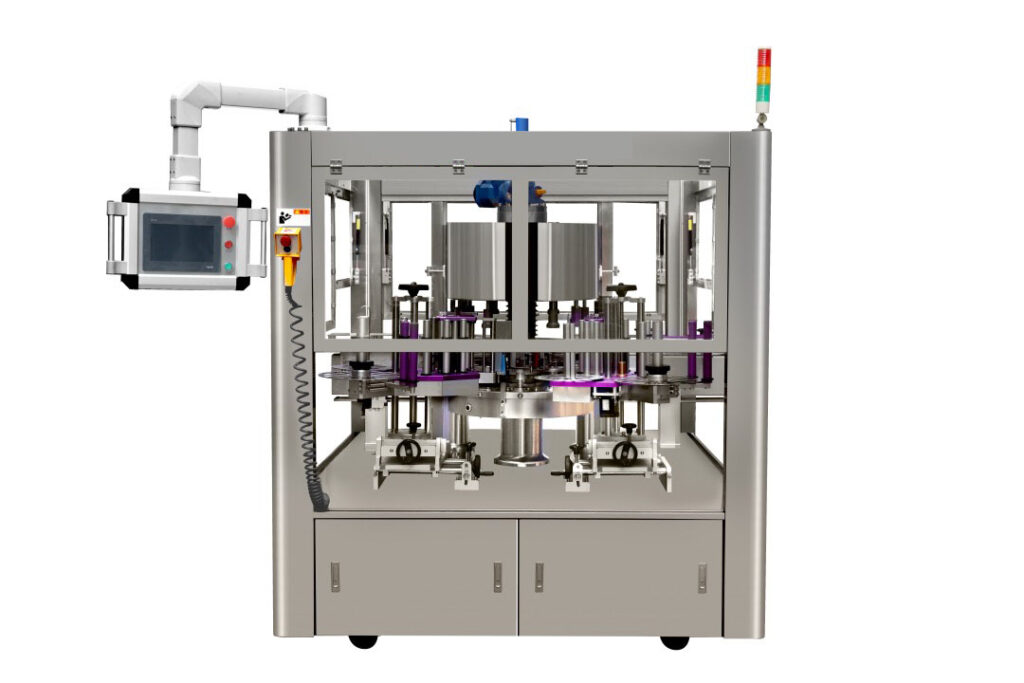

The Labeling Machine from EQS Machinery is a state-of-the-art solution for fast, efficient, and accurate labeling of a wide variety of containers and packages. Designed to meet the demanding needs of modern production environments, this machine combines cutting-edge technology with robust engineering to deliver unparalleled performance and reliability.

At the heart of the Labeling Machine is its high-speed operation, capable of applying labels at rates of up to 60,000 containers per hour. This lightning-fast throughput is made possible by advanced servo motors and precision control systems that ensure smooth, consistent label application without compromising quality or accuracy. Whether you’re labeling bottles, cans, jars, or any other type of packaging, this machine will keep your production lines moving at an impressive pace.

Whether you’re in the beverage, food, cosmetics, or any other industry that requires high-speed, high-efficiency, and precision labeling, the Labeling Machine from EQS Machinery is the perfect solution. With its unparalleled performance, reliability, and flexibility, this machine is poised to revolutionize your labeling operations and give your products the professional, consistent branding they deserve.

wide range of bottles labeling solution

Round Bottles,Square/Flat Bottles,Oval Bottles,Tapered Bottles,Shaped/Irregular Bottles

Round Bottles

Round Bottles

Square/Flat Bottles

Square/Flat Bottles

Oval Bottles

Oval Bottles

Tapered Bottles

Tapered Bottles

Don't hesitate to contact us for more information

jiangsu,suzhou zhangjiagang hexi rouad - china

Types of Labeling Machines

Adhesive labeling machines are widely used in industries such as pharmaceuticals, food, beverages, cosmetics, and daily chemical products. It can be applied to circular plastic bottles, glass bottles and other containers, as well as labeling of similar objects.

High-Speed Bottle Handling: Employs a screw bottle separation system combined with an infeed star wheel, ensuring smooth and stable product flow at high operational speeds.

User-Friendly Touch Screen Interface: Features a multilingual touch screen operating system with stepless speed adjustment. Capacity settings can be managed directly on the interface, automatically synchronizing the speeds of conveyors, screw bottle separators, and infeed/outfeed star wheels, eliminating the need for individual component adjustments.

Precision Positioning Labeling: Utilizes specialized sensors to collect positioning points, working in conjunction with servo station motors and a PLC control system to achieve highly accurate fixed-point labeling.

Advanced Label Applicator: Features a three-pillar structure with 8-dimensional adjustment, a three-stage spring clutch control, and an independent servo motor for backing paper rewind. This design ensures uniform tension and prevents backing paper tearing. The 1:1 design of the label dispensing wheel and backing paper rewind wheel accommodates multiple rolls of backing paper for extended operation.

The hot-melt adhesive labeling machine is an advanced model developed in recent years. It has the advantages of high design accuracy, rotary design, compact structure, beautiful appearance, strict processing requirements, meticulous assembly, good stability during high-speed operation, low glue consumption, and low operating costs for bottles and trademarks.

Superior Labeling Quality: Dedicated constant tension detection and feedback control systems, along with correction and guiding systems, guarantee high-quality labeling even with standard film materials.

Smooth Internal Transmission: The internal transmission system ensures smooth operation and simplifies machine adjustment.

Durable Bottle Handling: Screws, infeed star wheels, and bottle protection plates are made of wear-resistant nylon, minimizing bottle wear and tear.

High-Precision Gears: Gears in the transmission system are precision-engineered to class 7 standards, ensuring accurate and reliable transmission.

User-Friendly Interface: The human-machine interface displays real-time machine status, production output, hot melt adhesive temperature, and gluing temperature, facilitating easy troubleshooting. The interface is intuitive, and manual or jog start options are available for convenient setup and label changes.

Durable and Aesthetic Design: The protective cover frame is constructed from stainless steel with embedded organic glass. The stainless steel undergoes a brushed finish, providing a sleek and professional appearance.

The products on the conveyor line are separated at equal intervals by the bottle – dividing screw and arranged in sequence. When passing through the bottle – detecting photoelectric sensor, the servo – controlled drive unit will automatically feed a label. The cutter disc cuts the label, and at the same time, the lower label – brushing wheel set brushes down a long label, which is then sleeved onto the bottle. In the whole operation process, bottle dividing, label feeding, label cutting, and label sleeving are all controlled by servo motors, achieving precise and high – speed label sleeving.

High-Speed and Stable Operation: The reliable and optimized action configuration, coupled with a unique design, ensures high-speed operation of the label sleeving machine and significantly extends its service life.

Comprehensive Servo Motor Integration: Servo motors are extensively utilized to drive all systems, enabling precise transport, positioning, and shrinking of shrink film according to specified dimensions.

Enhanced Safety Performance: The design incorporates a human-machine harmony concept, allowing the equipment to automatically detect and prevent potential hazards resulting from improper human operation.

Simplified Packaging Material Replacement: The modular film-changing design facilitates easy and efficient replacement of packaging materials.

More Cases & Solutions

24000BPH Self Adhesive Labeling Machine

15000BPH Shrink Sleeve Labeling Machine

30000BPH Hot Melt Glue Labeling Machine

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.