Are Filling Machines Entirely Made of Stainless Steel?

leading paragraph:

Thinking about buying a filling machine? What it's made of matters!

snippet paragraph:

While many filling machines, especially those for food or sensitive products, use a lot of stainless steel, it's not always the whole machine. How much stainless steel is used depends on what the machine does and who makes it.

Transition Paragraph:

Let’s explore the materials used in filling machines and why stainless steel is so common.

What is a Filling Machine?

leading paragraph:

What exactly does a filling machine do?

snippet paragraph:

A filling machine is a device that: 1) Fills Containers: Dispenses liquids, powders, or granules into bottles, pouches, or other containers. 2) Ensures Accuracy: Measures the exact amount of product. 3) Increases Efficiency: Automates the filling process. 4) Maintains Hygiene: Keeps the filling process clean and sanitary.

Key Functions of Filling Machines

| Function | Description |

|---|---|

| Fills Containers | Filling machines accurately dispense liquids, powders, or granules into various types of containers, such as bottles, pouches, and jars. |

| Ensures Accuracy | These machines measure the precise amount of product being filled, ensuring consistent fill levels and reducing waste. |

| Increases Efficiency | By automating the filling process, these machines significantly increase production speed and reduce manual labor. |

| Maintains Hygiene | Filling machines are designed to maintain a clean and sanitary filling environment, preventing contamination of the product. |

What is the Process of Filling a Machine?

leading paragraph:

How does a filling machine work step-by-step?

snippet paragraph:

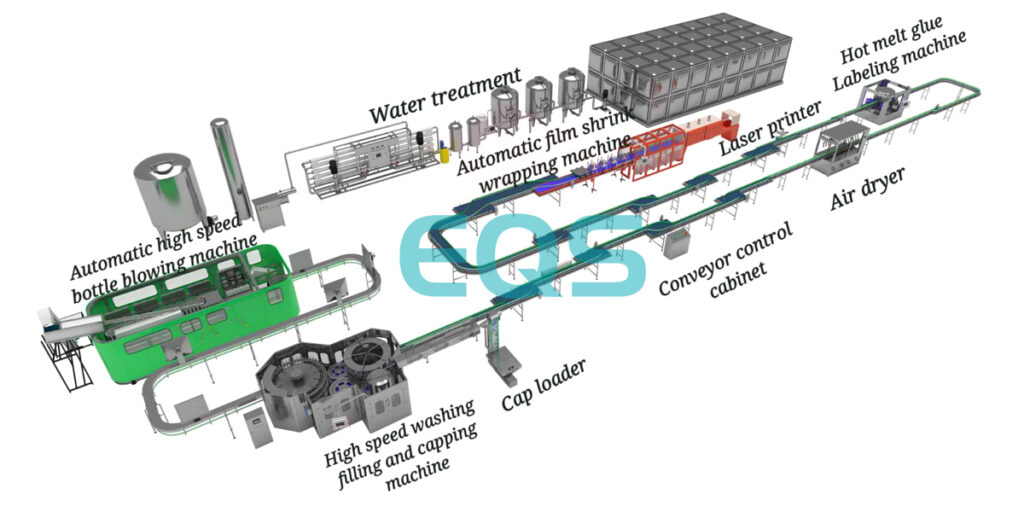

The filling process usually involves: 1) Container Loading: Placing empty containers. 2) Product Dispensing: Filling containers with the right amount of product. 3) Sealing/Capping: Closing the filled containers. 4) Output: Moving filled containers to the next stage.

Filling Process Breakdown

| Step | Description |

|---|---|

| Container Loading | Empty containers are loaded onto the machine, either manually or automatically. |

| Product Dispensing | The machine dispenses the precise amount of product into each container using various filling mechanisms. |

| Sealing/Capping | Once filled, the containers are sealed or capped to prevent leakage and maintain product integrity. |

| Output | The filled and sealed containers are then moved to the next stage of the production line for labeling or packaging. |

What is a Liquid Filling Machine in the Pharmaceutical Industry?

leading paragraph:

How are filling machines used for medicine?

snippet paragraph:

In pharmaceuticals, liquid filling machines must: 1) Be Sterile: Prevent contamination. 2) Ensure Accuracy: Guarantee precise dosages. 3) Meet Regulations: Follow strict industry standards. 4) Handle Viscous Liquids: Fill syrups and other thick solutions.

Key Requirements for Pharmaceutical Filling Machines

| Requirement | Description |

|---|---|

| Sterility | Pharmaceutical filling machines must be designed to maintain a sterile environment to prevent contamination of the product. |

| Accuracy | These machines must ensure precise dosing to guarantee the safety and efficacy of the medication. |

| Regulatory Compliance | Pharmaceutical filling machines must comply with strict industry standards and regulations, such as GMP. |

| Viscous Liquids | These machines must be capable of handling a wide range of liquid viscosities, including syrups and thick solutions. |

How Does a Bottle Filling Machine Work?

leading paragraph:

How do bottle filling machines actually work?

snippet paragraph:

Bottle filling machines work by: 1) Positioning Bottles: Securing bottles for filling. 2) Dispensing Product: Using nozzles or pumps. 3) Controlling Volume: Measuring the amount of liquid. 4) Moving Bottles: Transporting filled bottles out.

Operational Steps of a Bottle Filling Machine

| Step | Description |

|---|---|

| Positioning Bottles | The machine positions and secures empty bottles to ensure accurate filling. |

| Dispensing Product | Nozzles or pumps dispense the liquid product into the bottles, controlling the flow rate and volume. |

| Volume Control | The machine measures the amount of liquid being dispensed to ensure consistent fill levels. |

| Moving Bottles | Once filled, the bottles are transported out of the filling area for capping and further processing. |

Conclusion

In conclusion, while many parts of filling machines are made of stainless steel, it’s not always the case for the entire machine. The use of stainless steel depends on the machine's specific purpose and the manufacturer's design.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.