In-depth Analysis of the Bottled Water Filling Production Line Process

leading paragraph:

Ever wonder how bottled water gets made? Let's dive in!

snippet paragraph:

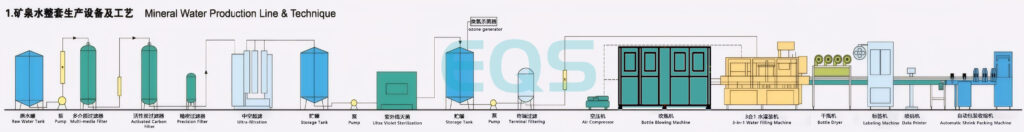

The bottled water filling production line involves several key stages: water treatment, bottle blowing (or receiving pre-made bottles), rinsing, filling, capping, labeling, and packaging. Each step ensures the water is safe, the bottles are clean, and the final product is ready for consumers. Understanding this process highlights the technology and precision involved in producing bottled water.

Transition Paragraph:

Let's explore each stage of the bottled water filling production line in detail.

Water Treatment: Ensuring Purity and Safety

leading paragraph:

Clean water starts with thorough treatment!

snippet paragraph:

Water treatment is the first and most crucial step. It involves filtration, disinfection, and purification to remove impurities, bacteria, and other contaminants. Common methods include reverse osmosis, UV sterilization, and ozonation. Proper water treatment ensures the bottled water meets strict safety and quality standards.

Water Treatment Methods

- Reverse Osmosis: Removes dissolved solids.

- UV Sterilization: Kills bacteria with UV light.

- Ozonation: Disinfects using ozone.

- Filtration: Removes particles and sediment

- Activated Carbon: Removes chlorine and odors

Dive deeper Paragraph:

Water treatment is a critical initial step in the bottled water production line, ensuring that the water is purified to meet stringent safety and quality standards. This process typically involves a combination of filtration, disinfection, and purification techniques to remove any impurities, bacteria, or other contaminants that may be present in the source water.

Reverse Osmosis

Reverse osmosis (RO) is a highly effective method for removing dissolved solids, minerals, and other impurities from the water. In this process, water is forced through a semi-permeable membrane that filters out contaminants, leaving behind pure, clean water.

UV Sterilization

UV sterilization is used to kill bacteria, viruses, and other microorganisms that may be present in the water. The water is exposed to ultraviolet (UV) light, which disrupts the DNA of these microorganisms, rendering them harmless.

Bottle Blowing : Creating the Containers

leading paragraph:

Bottles from scratch or pre-made?

snippet paragraph:

Some lines include bottle blowing, where plastic pellets are heated and molded into bottles. Others receive pre-made bottles. If blowing bottles, quality control is crucial to ensure consistent shape and thickness. Whether made in-house or received, bottles must be clean and ready for filling.

Bottle Creation Options

- Bottle Blowing: Molding bottles from plastic.

- Pre-made Bottles: Receiving ready-to-fill containers.

- Quality Control: Ensuring bottle consistency.

- Material Inspection: Verifying plastic quality

- Hygienic Storage: Keeping bottles clean before use

Dive deeper Paragraph:

The creation or acquisition of bottles is a crucial step in the bottled water production line. Some production lines include an integrated bottle blowing process, where plastic pellets are heated and molded into bottles on-site. In other cases, pre-made bottles are received from external suppliers.

Bottle Blowing

For production lines that include bottle blowing, plastic pellets are fed into a molding machine, where they are heated and shaped into bottles. Quality control is essential during this process to ensure that the bottles have a consistent shape, thickness, and structural integrity.

Pre-made Bottles

Alternatively, some production lines receive pre-made bottles from external suppliers. In this case, the bottles must be carefully inspected to ensure that they meet the required quality standards and are free from any defects or contaminants.

Rinsing: Preparing Bottles for Filling

leading paragraph:

Clean bottles are a must!

snippet paragraph:

Before filling, bottles are rinsed to remove any dust or particles. This typically involves inverting the bottles and spraying them with purified water or air. A clean bottle ensures the water's purity is maintained. Rinsing is a critical step in preventing contamination.

Rinsing Process Benefits

- Dust Removal: Removes any particles.

- Purified Water/Air: Ensures cleanliness.

- Contamination Prevention: Maintains water quality.

- Inverted Bottles: Efficient cleaning

- Automated System: Consistent rinsing

Dive deeper Paragraph:

Rinsing is a crucial step in the bottled water production line, as it ensures that the bottles are clean and free from any dust, particles, or other contaminants before they are filled with water. This process is essential for maintaining the purity and quality of the bottled water.

Dust Removal

The rinsing process effectively removes any dust, particles, or debris that may have accumulated inside the bottles during storage or transportation. This helps to prevent contamination of the water.

Purified Water or Air

The bottles are typically rinsed with purified water or filtered air to ensure that no additional contaminants are introduced during the rinsing process. This helps to maintain the purity of the water.

Filling: Dispensing the Purified Water

leading paragraph:

The heart of the operation!

snippet paragraph:

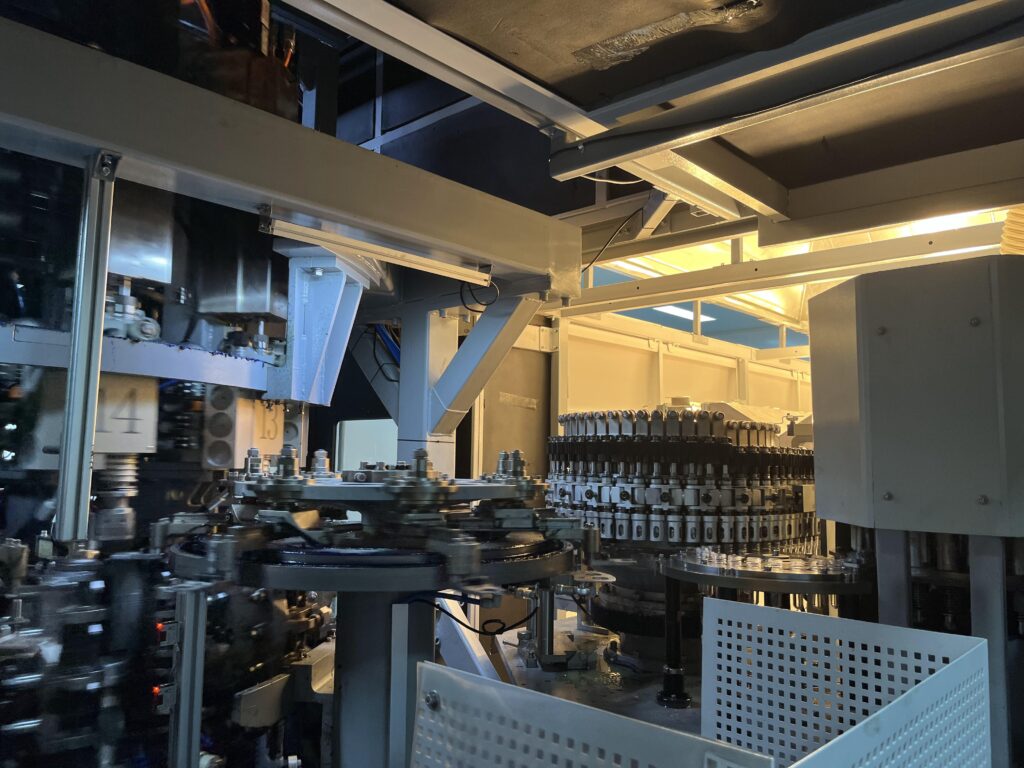

The filling stage involves dispensing the purified water into the bottles. This is done using automated filling machines that ensure accurate and consistent fill levels. Proper filling minimizes spillage and ensures each bottle contains the correct amount of water. Filling machines must be regularly sanitized.

Filling Machine Features

- Automated Filling: Consistent dispensing.

- Accurate Levels: Correct water amount.

- Spillage Reduction: Minimizes waste.

- Sanitization: Prevents contamination

- High-Speed Operation: Efficient filling

Dive deeper Paragraph:

The filling stage is a critical step in the bottled water production line, where purified water is dispensed into the bottles. This process is typically carried out using automated filling machines that are designed to ensure accurate and consistent fill levels in each bottle.

Automated Filling

The filling machines are fully automated, which means that they can fill bottles quickly and efficiently without the need for manual intervention. This helps to increase the overall throughput of the production line.

Accurate Levels

The filling machines are equipped with sensors and controls that ensure accurate and consistent fill levels in each bottle. This is important for meeting regulatory requirements and ensuring that consumers receive the correct amount of water.

Capping: Sealing the Bottles

leading paragraph:

Sealing in the freshness!

snippet paragraph:

Capping involves securely sealing the filled bottles with caps. Automated capping machines ensure caps are tightly sealed to prevent leaks and contamination. Proper capping is essential for maintaining the water's purity and preventing tampering. Caps are often sanitized before application.

Capping Machine Advantages

- Secure Sealing: Prevents leaks.

- Tamper-Evident: Ensures safety.

- Automated Process: Efficient capping.

- Consistent Torque: Uniform tightness

- Hygienic Handling: Prevents cap contamination

Dive deeper Paragraph:

Capping is a critical step in the bottled water production line, where the filled bottles are securely sealed with caps to prevent leaks, contamination, and tampering. This process is typically carried out using automated capping machines that are designed to ensure that the caps are properly applied and tightened.

Secure Sealing

The capping machines are designed to apply the caps securely to the bottles, creating a tight seal that prevents any leaks or spills. This is essential for maintaining the quality and safety of the bottled water during storage and transportation.

Tamper-Evident

Many capping machines also apply tamper-evident seals to the bottles, which provide an additional layer of protection against tampering. These seals are designed to break or tear if the bottle has been opened, providing a clear indication to consumers that the product may have been compromised.

Labeling: Adding Product Information and Branding

leading paragraph:

Making each bottle stand out!

snippet paragraph:

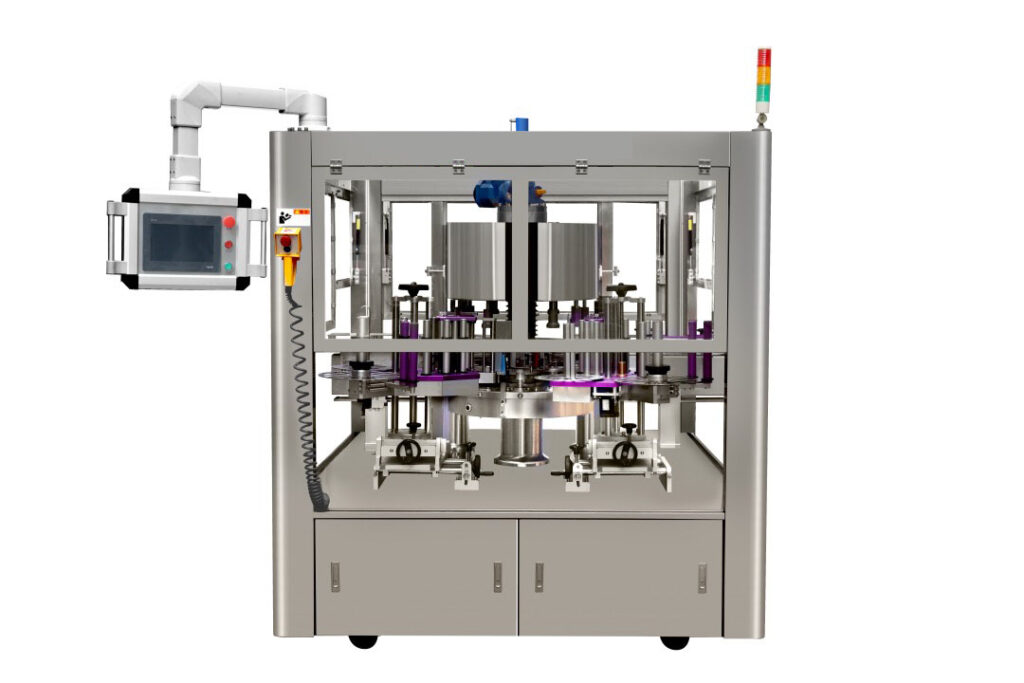

Labeling applies labels with product information, branding, and nutritional facts. Automated labeling machines ensure accurate placement and secure adhesion. Labels enhance the product's appearance and provide essential information to consumers. Proper labeling is crucial for compliance and marketing.

Labeling Benefits

- Product Information: Informs consumers.

- Branding: Enhances product appeal.

- Compliance: Meets regulations.

- Automated Application: Efficient labeling

- Secure Adhesion: Prevents peeling

Dive deeper Paragraph:

Labeling is an essential step in the bottled water production line, where labels are applied to the bottles to provide product information, branding, and nutritional facts to consumers. This process is typically carried out using automated labeling machines that are designed to ensure accurate placement and secure adhesion of the labels.

Product Information

The labels provide consumers with important information about the product, such as the brand name, product description, ingredients, nutritional facts, and any certifications or endorsements.

Branding

The labels also play a crucial role in branding the product and enhancing its appeal to consumers. They often feature eye-catching graphics, logos, and slogans that help to differentiate the product from its competitors.

Packaging: Preparing for Distribution

leading paragraph:

Ready for the shelves!

snippet paragraph:

Packaging prepares the labeled bottles for distribution. This may involve shrink-wrapping, boxing, or palletizing. Proper packaging protects the bottles during transport and storage. Efficient packaging ensures products reach consumers in good condition. Automated packaging systems streamline this final stage.

Packaging Methods

- Shrink-Wrapping: Bundling bottles together.

- Boxing: Placing bottles in cartons.

- Palletizing: Stacking boxes on pallets.

- Automated Systems: Streamlined process

- Protection During Transport: Minimizes damage

Dive deeper Paragraph:

Packaging is the final step in the bottled water production line, where the labeled bottles are prepared for distribution to retailers and consumers. This process typically involves shrink-wrapping, boxing, or palletizing the bottles to protect them during transport and storage.

Shrink-Wrapping

Shrink-wrapping involves bundling several bottles together using a clear plastic film that is heat-shrunk to create a tight, secure package. This method is commonly used for multi-packs of bottled water.

Boxing

Boxing involves placing individual bottles or multi-packs into cardboard cartons or boxes. This provides additional protection during transport and storage and makes it easier to stack and handle the products.

Conclusion

From clean water to labeled bottles, it's quite a process! Each step matters.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.