How to Maintain a Bottle Blowing Machine?

leading paragraph:

Want your bottle blowing machine to last? Regular maintenance is key!

snippet paragraph:

Maintaining a bottle blowing machine involves regular cleaning, lubrication, and inspections. This ensures the machine runs efficiently, prevents breakdowns, and extends its lifespan.

Transition Paragraph:

Let’s look at the key steps and best practices to keep your machine in top condition.

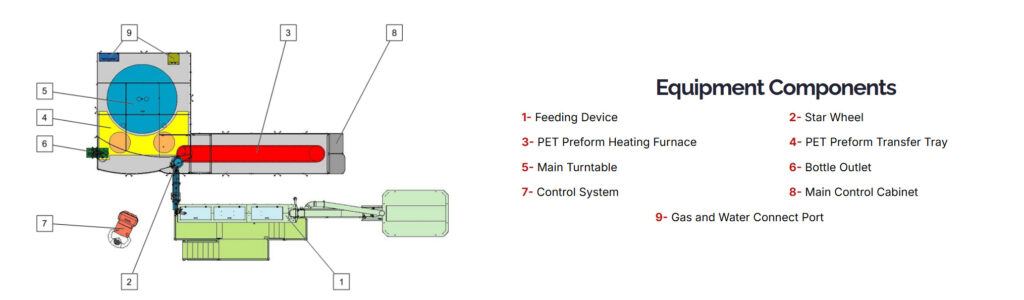

How to Operate a Blowing Machine Step by Step?

leading paragraph:

Not sure how to use a blowing machine? Here's a quick guide.

snippet paragraph:

Operating a blowing machine involves: 1) Preparation: Check the machine and materials. 2) Loading: Load preforms into the machine. 3) Setting Parameters: Set temperature, pressure, and time. 4) Starting the Cycle: Initiate the blowing process. 5) Monitoring: Observe the process for any issues. 6) Unloading: Remove finished bottles.

Detailed Operation Steps

| Step | Description |

|---|---|

| Preparation | Ensure the machine is clean, properly connected to power and air, and materials are ready. |

| Loading | Load PET preforms into the hopper or feeding system. |

| Setting Parameters | Adjust the temperature, blowing pressure, and cycle time based on the material and bottle design. |

| Starting the Cycle | Press the start button to begin the automatic blowing process. |

| Monitoring | Observe the machine for any malfunctions, such as uneven heating or improper bottle formation. |

| Unloading | Once the cycle is complete, remove the finished bottles. |

I always double-check the settings before starting a new cycle to avoid errors and waste.

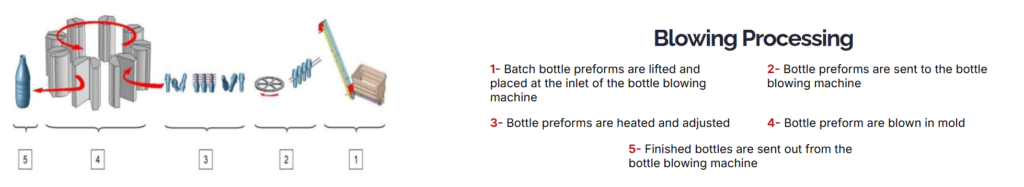

What are the Steps in the Blowing Process of a PET Bottle?

leading paragraph:

What does the PET bottle blowing process entail?

snippet paragraph:

The steps include: 1) Preform Heating: PET preforms are heated to a pliable temperature. 2) Stretching: The preform is stretched lengthwise. 3) Blowing: Compressed air inflates the preform against the mold. 4) Cooling: The bottle is cooled to set its shape. 5) Ejection: The finished bottle is ejected from the mold.

PET Bottle Blowing Steps

| Step | Description |

|---|---|

| Preform Heating | PET preforms are heated using infrared lamps to achieve the right temperature for stretching. |

| Stretching | A stretch rod extends the preform vertically to distribute the material evenly. |

| Blowing | High-pressure air is injected into the preform, expanding it to fit the mold cavity. |

| Cooling | The mold is cooled with water or air to quickly solidify the PET material. |

| Ejection | The mold opens, and the finished PET bottle is ejected. |

What is the Purpose of Blowing Machine?

leading paragraph:

What is the reason for using a blowing machine?

snippet paragraph:

The purpose of a blowing machine is to manufacture hollow plastic products, like bottles, containers, and toys. It uses compressed air to inflate heated plastic inside a mold, creating the desired shape. This process is efficient for mass production and allows for complex designs.

Key Purposes

| Purpose | Description |

|---|---|

| Hollow Products | Creates hollow items, such as bottles and containers. |

| Mass Production | Efficiently produces large quantities of identical products. |

| Complex Designs | Allows for intricate shapes and custom designs. |

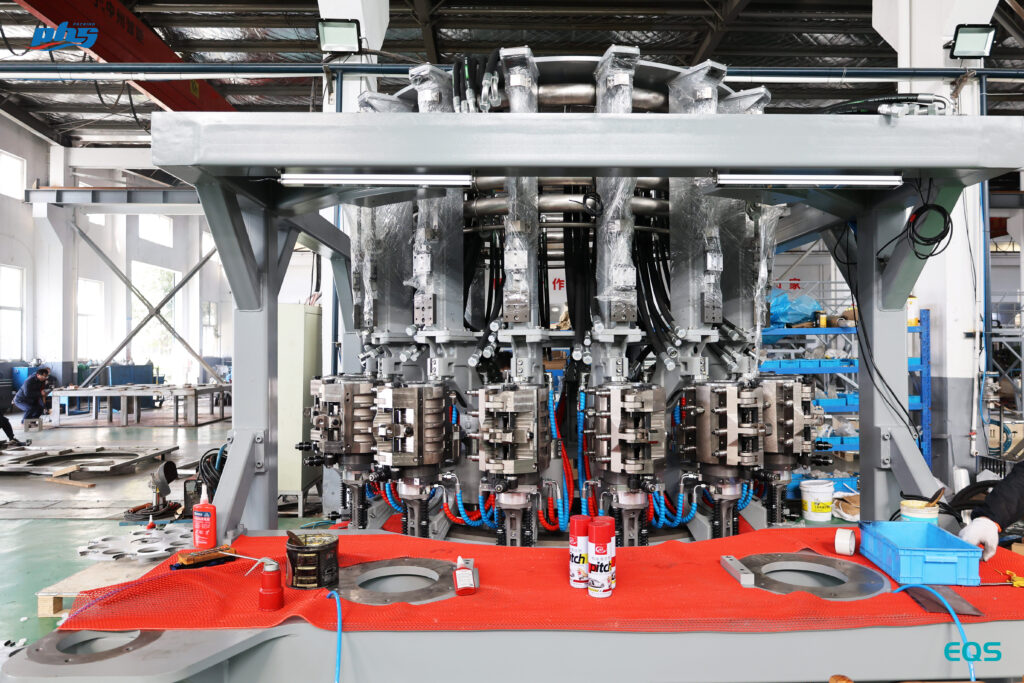

What is a Bottle Blower?

leading paragraph:

What exactly is a bottle blower?

snippet paragraph:

A bottle blower is a machine that uses compressed air to inflate heated plastic inside a mold to form bottles. It automates the process of bottle production, ensuring consistent quality and high output. These machines are crucial for the beverage, food, and packaging industries.

Key Aspects

| Aspect | Description |

|---|---|

| Automation | Automates the bottle-making process, reducing manual labor. |

| Consistency | Ensures uniform bottle quality and dimensions. |

| High Output | Produces large quantities of bottles quickly and efficiently. |

Conclusion

To keep your bottle blowing machine running smoothly, make sure to clean, lubricate and inspect it regularly. Doing these things can help avoid problems and keep the machine running for longer.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality bottle blowing machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.