How do carbonated beverages work? How are they created?

Ever wondered what makes your soda fizzy or your sparkling water so refreshing? The secret lies in tiny bubbles!

Carbonated beverages get their fizz from dissolved carbon dioxide gas. This happens when carbon dioxide is forced into a liquid under pressure. When you open the container, the pressure releases, and those bubbles escape, giving you that satisfying fizz.

So, how exactly do manufacturers create this bubbly magic? Let's dive deeper into the fascinating world of carbonated beverage production.

How are carbonated beverages made?

Making carbonated drinks seems like magic, but it's actually a carefully controlled process. Want to know the steps?

The key steps in making carbonated beverages include purifying water, mixing ingredients, carbonating the liquid by injecting CO2 under pressure, and then filling and packaging the final product.

The process involves several key stages.

First, water purification is essential, as water makes up most of the drink. It undergoes filtration, reverse osmosis, or distillation to remove impurities.

Next, syrup preparation involves blending sweeteners (like sugar or high-fructose corn syrup), flavors, preservatives, and colors. The exact recipe depends on the type of drink.

Then comes carbonation, where carbon dioxide (CO2) is injected into the liquid under high pressure. The amount of CO2 is adjusted based on the desired level of fizziness.

Finally, the carbonated liquid is filled into bottles or cans under pressure to retain the CO2, sealed, and labeled. It’s a pretty streamlined operation! I've seen this firsthand when touring some beverage factories in China, the speed and precision of these lines are really impressive.

What is the mechanism of carbonated drinks?

What's the science behind that satisfying fizz? It all comes down to a fundamental law of chemistry.

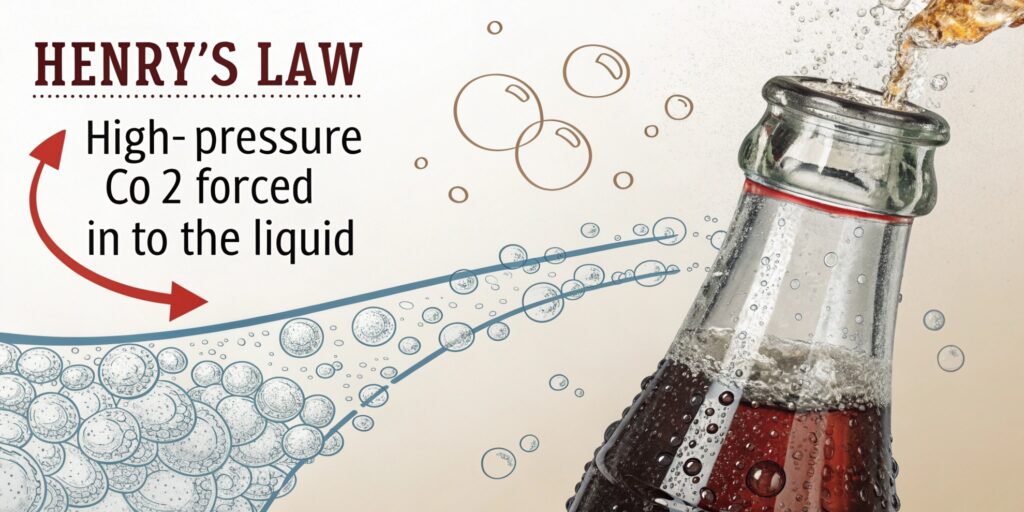

The mechanism of carbonated drinks relies on Henry's Law, which states that the amount of gas dissolved in a liquid is proportional to the pressure. High pressure forces CO2 into the liquid; when released, the CO2 escapes as bubbles.

Here's how it works:

| Step | Explanation |

|---|---|

| 1. High Pressure | During manufacturing, carbon dioxide gas is pumped into the beverage at high pressure. |

| 2. Dissolving CO2 | According to Henry's Law, the higher the pressure, the more CO2 dissolves in the liquid. |

| 3. Equilibrium | The CO2 molecules distribute themselves evenly throughout the liquid until an equilibrium is reached. |

| 4. Opening the Container | When you open the bottle or can, the pressure is released. |

| 5. Bubble Formation | With the pressure reduced, the dissolved CO2 becomes unstable and starts to escape from the solution in the form of bubbles. |

Think about what happens when you open a soda bottle. The pressure inside drops, and suddenly, all those CO2 molecules that were happily dissolved start rushing out, creating the fizz. Henry's Law helps us understand and predict this behavior, ensuring we get the perfect level of carbonation. I remember learning about this in chemistry class and finally understanding why my soda went flat if I left it open too long!

How do you manufacture carbonated water?

Want to make your own sparkling water? It's easier than you think, whether at home or on an industrial scale!

Manufacturing carbonated water involves purifying water, chilling it, and then injecting carbon dioxide under high pressure. This can be done using specialized equipment or even at home with a soda maker.

There are a couple of ways to manufacture carbonated water:

- Forced Carbonation: This is the most common method, especially in commercial production. It involves chilling the water and then injecting CO2 gas under high pressure in a carbonation tank. The cold temperature and high pressure help the CO2 dissolve efficiently.

-

Natural Carbonation: This method relies on natural fermentation processes to produce CO2. It's mainly used for beverages like beer, where yeast consumes sugars and releases CO2 as a byproduct.

For home use, soda makers provide a convenient way to force carbonate water. These devices use CO2 cartridges to inject the gas into a bottle of water, creating sparkling water in seconds.

When EQS designs production lines, we always consider the client's desired output and preferred method of carbonation to ensure the system is perfectly tailored to their needs.

What do they put in drinks to make them carbonated?

It's more than just carbon dioxide! Other ingredients play a vital role in the taste and preservation of your favorite fizzy drinks.

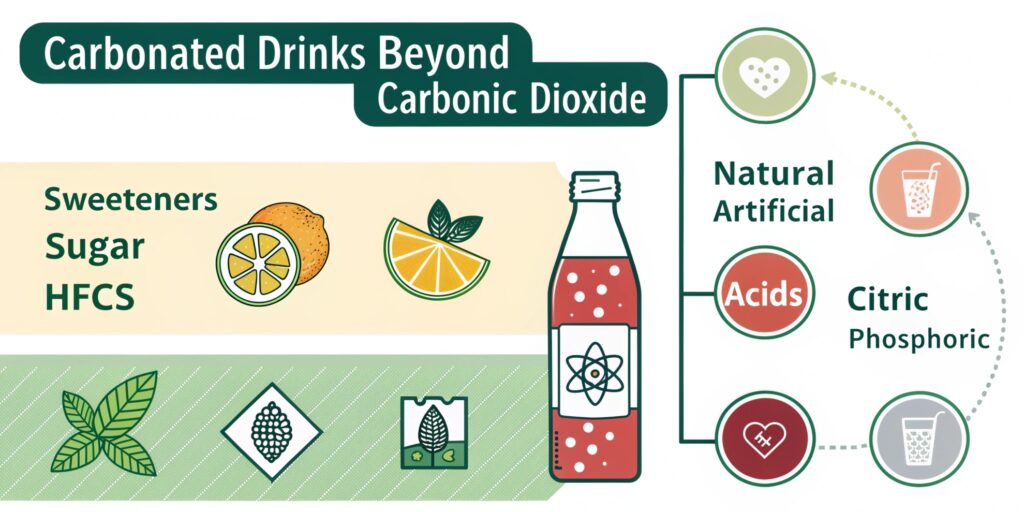

Besides carbon dioxide and water, carbonated drinks often contain sweeteners (sugar, HFCS, or artificial), flavors (natural or artificial), and acids (citric or phosphoric) for tanginess and preservation.

Here's a breakdown of common ingredients:

| Ingredient | Purpose | Example |

|---|---|---|

| Carbon Dioxide (CO2) | Provides the fizz and bubbles | All carbonated beverages |

| Water | The primary liquid component | Most carbonated beverages use purified water |

| Sweeteners | Adds sweetness | Sugar, high-fructose corn syrup, aspartame, stevia |

| Flavors | Provides specific tastes | Fruit extracts, artificial flavorings |

| Acids | Adds a tangy taste and acts as a preservative | Citric acid, phosphoric acid |

| Colors | Enhances visual appeal | Artificial colors, natural colors |

| Minerals | Can enhance flavor and mouthfeel | Potassium bicarbonate, sodium citrate |

The specific combination and concentration of these ingredients vary widely depending on the type of carbonated drink. For example, colas often contain caffeine and phosphoric acid, while sparkling waters may only contain carbon dioxide and added minerals for taste. It’s really interesting how different combinations can create such a wide range of flavors and experiences.

Conclusion

Carbonated beverages are a delightful mix of science and flavor, making them a global favorite. Next time you pop open a soda, you’ll know exactly what makes it so fizzy and refreshing!

My name is Allen, and I'm an expert in filling machine technology at EQS (www.eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your beverage production line, feel free to reach out to me at [email protected]

. We specialize in providing customizable solutions with cutting-edge technology.