Hot Fill Bottling Machines: A Complete Guide on Hot-fill Process

leading paragraph:

Ever wondered how some drinks can sit on a shelf for so long without spoiling? The secret? Hot fill bottling!

snippet paragraph:

Hot fill bottling machines use a hot-fill process where beverages are filled into containers at high temperatures (typically 85-92°C or 185-197.6°F) to sterilize both the product and the packaging. This method extends shelf life by eliminating spoilage-causing microorganisms.

Transition Paragraph:

Let's dive into the details of how hot fill bottling works and why it's so effective.

What is Hot Fill Bottling?

leading paragraph:

What's the basic idea behind hot fill?

snippet paragraph:

Hot fill bottling is a process where beverages are heated to a high temperature and then filled into containers that can withstand the heat. This process sterilizes the product and the inside of the container, ensuring a longer shelf life without the need for preservatives.

Core Concepts of Hot Fill

| Concept | Description |

|---|---|

| High Temperature | Beverages are heated to temperatures that kill microorganisms, typically between 82-95°C (180-203°F). |

| Container Heat Resistance | Containers must be able to withstand high temperatures without deforming or leaching chemicals. |

| Sterilization | The hot fill process sterilizes both the beverage and the interior of the container, eliminating spoilage-causing bacteria, yeasts, and molds. |

Dive deeper Paragraph:

The hot fill bottling process is a method used to preserve beverages by sterilizing both the product and its packaging. This is achieved by heating the beverage to a high temperature, typically between 85-92°C (185-197.6°F), and then filling it into a heat-resistant container. The heat from the beverage kills any microorganisms present in the product and on the inner surfaces of the container, effectively sterilizing both. For example, a juice manufacturer found that by switching to a hot fill process, they were able to extend the shelf life of their products from a few weeks to several months without adding any preservatives. This not only reduced their production costs but also appealed to consumers who were looking for natural and preservative-free options.

How Does a Hot Fill Bottling Machine Work?

leading paragraph:

What are the key steps in the hot fill process?

snippet paragraph:

A hot fill bottling machine typically involves these steps: 1) Heating: The beverage is heated to a high temperature. 2) Filling: The hot beverage is filled into sterilized containers. 3) Capping: Containers are immediately sealed to prevent contamination. 4) Cooling: Bottles are cooled to ensure the container maintains its shape and integrity.

Steps in the Hot Fill Process

| Step | Description |

|---|---|

| Heating | The beverage is heated to a specific temperature to kill microorganisms. |

| Filling | The heated beverage is filled into containers, often using a rotary filling system for efficiency. |

| Capping | Containers are immediately capped to prevent any airborne contaminants from entering. |

| Cooling | Bottles are cooled, often by inverting them, to sterilize the cap area. This helps the container maintain its shape as the product cools and contracts. |

Dive deeper Paragraph:

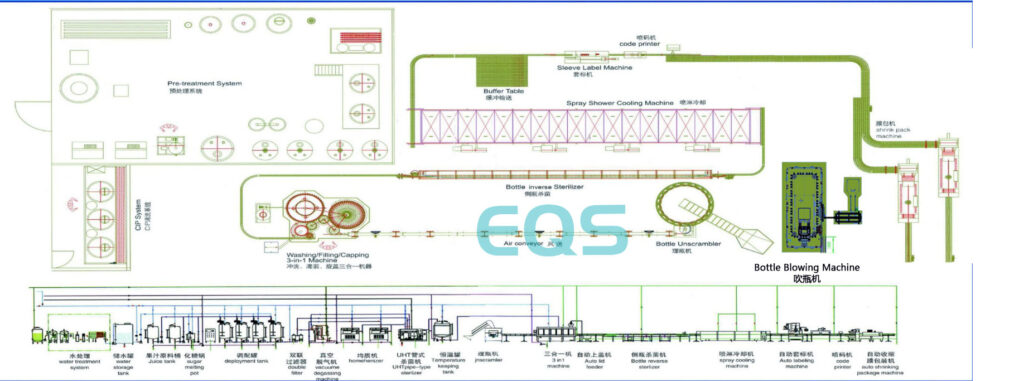

The operation of a hot fill bottling machine involves a sequence of precisely controlled steps to ensure effective sterilization and preservation of the beverage. First, the beverage is heated to the required temperature using a heat exchanger or other heating system. Then, the heated liquid is transferred to the filling station, where it is dispensed into the containers. The filling process is often automated using a rotary filling system, which allows for high-speed and accurate filling. After filling, the containers are immediately capped to prevent any contamination. Finally, the bottles are cooled to ensure the container maintains its shape as the product cools and contracts. For instance, a beverage company in Asia implemented a hot fill bottling line to produce ready-to-drink teas. The automated process ensured consistent quality and extended the shelf life of their products, allowing them to expand their distribution network.

What Types of Beverages Are Suitable for Hot Fill?

leading paragraph:

What drinks work best with the hot fill method?

snippet paragraph:

Hot fill is commonly used for: 1) Juices: Fruit and vegetable juices benefit from the extended shelf life. 2) Teas: Ready-to-drink teas are often hot-filled. 3) Sauces: Some sauces and condiments are also hot-filled. 4) Sports Drinks: Certain sports and energy drinks use this method.

Common Hot-Filled Beverages

| Beverage Type | Example |

|---|---|

| Juices | Apple juice, orange juice, grape juice |

| Teas | Ready-to-drink iced tea, herbal tea, green tea |

| Sauces | Tomato sauce, pasta sauce, BBQ sauce |

| Sports Drinks | Electrolyte drinks, energy drinks |

Dive deeper Paragraph:

The hot fill process is particularly well-suited for beverages that are susceptible to microbial growth and spoilage. Juices, teas, and certain types of sauces are ideal candidates for hot fill because they often contain sugars and other nutrients that can support microbial growth. By hot-filling these products, manufacturers can eliminate the need for chemical preservatives, which are often undesirable to consumers. For example, a company that produces organic fruit juices adopted a hot fill process to ensure that their products remained free from artificial additives. The hot fill process allowed them to maintain the natural flavor and nutritional content of their juices while also extending their shelf life. This decision not only increased their market share but also enhanced their brand image as a provider of healthy and natural beverages.

What Are the Advantages of Hot Fill Bottling?

leading paragraph:

Why choose hot fill over other methods?

snippet paragraph:

Hot fill offers several advantages: 1) Extended Shelf Life: Products last longer without preservatives. 2) Reduced Preservatives: Minimizes or eliminates the need for artificial preservatives. 3) Cost-Effective: Reduces costs associated with refrigeration and distribution. 4) Safe: Ensures products are safe for consumption by eliminating harmful microorganisms.

Key Benefits of Hot Fill

| Benefit | Description |

|---|---|

| Extended Shelf Life | The hot fill process eliminates spoilage-causing microorganisms, allowing products to be stored for longer periods without refrigeration. |

| Reduced Preservatives | By sterilizing the product and container, the need for artificial preservatives is minimized or eliminated, appealing to health-conscious consumers. |

| Cost-Effective | Hot fill reduces the costs associated with refrigeration during storage and distribution, as well as the cost of preservatives. |

| Enhanced Safety | The hot fill process ensures that products are safe for consumption by eliminating harmful microorganisms. |

Dive deeper Paragraph:

The economic and environmental benefits of hot fill bottling make it an attractive option for many beverage manufacturers. By extending the shelf life of products, hot fill reduces waste and lowers the costs associated with refrigeration and distribution. This can be particularly beneficial for companies that operate in regions with limited access to refrigeration or that distribute their products over long distances. Furthermore, the reduced need for chemical preservatives aligns with consumer preferences for natural and healthy products. A study conducted by a food industry research group found that companies that switched to hot fill bottling experienced a significant reduction in their overall production costs and a corresponding increase in their market share. This demonstrates the potential of hot fill to improve both the profitability and sustainability of beverage production.

What Are the Challenges of Hot Fill Bottling?

leading paragraph:

Are there any downsides to using hot fill?

snippet paragraph:

Despite its benefits, hot fill has challenges: 1) Container Limitations: Not all containers can withstand high temperatures. 2) Flavor Impact: High heat can sometimes affect the flavor of sensitive beverages. 3) Cooling Process: Proper cooling is essential to prevent container deformation. 4) Energy Consumption: Heating and cooling require significant energy.

Potential Drawbacks of Hot Fill

| Challenge | Description |

|---|---|

| Container Limitations | Not all types of containers, especially certain plastics, can withstand the high temperatures required for hot fill. |

| Flavor Impact | The high heat can sometimes alter the flavor profile of sensitive beverages, requiring careful temperature control and formulation adjustments. |

| Cooling Process | Inadequate cooling can lead to container deformation, requiring precise cooling methods to maintain the integrity of the packaging. |

| Energy Consumption | The heating and cooling processes in hot fill can be energy-intensive, leading to higher operational costs and environmental impact if not optimized. |

Dive deeper Paragraph:

While hot fill bottling offers numerous advantages, it also presents certain challenges that manufacturers must address to ensure the quality and safety of their products. One of the primary challenges is selecting the right type of container that can withstand the high temperatures required for the process. Certain plastics, such as polyethylene terephthalate (PET), Using PET bottles for hot filling requires increasing the thickness of the bottles, which can result in higher costs compared to regular bottles. Another challenge is the potential impact of high heat on the flavor and nutritional content of sensitive beverages. Some vitamins and antioxidants can be degraded by heat, requiring careful temperature control and formulation adjustments. For example, a company producing vitamin-enhanced beverages had to reformulate their product to account for the loss of certain nutrients during the hot fill process. Addressing these challenges requires expertise in food science, packaging technology, and process optimization.

Conclusion

Hot fill bottling is a highly effective method for preserving beverages, offering extended shelf life and reduced reliance on preservatives. While it presents some challenges, the benefits often outweigh the drawbacks, making it a popular choice for many beverage manufacturers.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.