Glass Bottle Washing Machine: A Complete Guide To Industrial Cleaning Glass Bottle Solutions

leading paragraph:

Dirty bottles? Not anymore! Discover industrial glass bottle washing solutions.

snippet paragraph:

Glass bottle washing machines are essential for industries that reuse glass bottles. These machines provide efficient, thorough cleaning and sterilization, ensuring bottles are free from contaminants before refilling.

Transition Paragraph:

Let's dive into the world of industrial glass bottle washing and explore the best solutions for your business.

Why are Glass Bottle Washing Machines Important?

leading paragraph:

Cleanliness is key! Why invest in a glass bottle washer?

snippet paragraph:

Glass bottle washing machines ensure hygiene and safety in beverage production. They remove contaminants, prevent cross-contamination, and meet regulatory standards, safeguarding consumer health and product quality.

Key Benefits

- Hygiene: Ensuring cleanliness.

- Safety: Protecting consumers.

- Contaminant Removal: Eliminating impurities.

- Cross-Contamination Prevention: Avoiding mixing.

- Regulatory Compliance: Meeting standards.

- Product Quality: Maintaining integrity.

Dive deeper Paragraph:

Glass bottle washing machines are not just about aesthetics; they are crucial for ensuring hygiene and safety in beverage production. By thoroughly cleaning and sterilizing bottles, these machines remove potential contaminants such as bacteria, mold, and residual product from previous use. This process is essential for preventing cross-contamination, where harmful substances can transfer from one batch of product to another, potentially compromising the safety and quality of the beverage.

Types of Glass Bottle Washing Machines

leading paragraph:

So many choices! Which bottle washer is right for you?

snippet paragraph:

Different types of glass bottle washing machines cater to various production needs. high-pressure are ideal for high-volume operations, while linear type washers suit smaller batches. Other types include immersion washers and spray washers, each with unique cleaning mechanisms.

Washing Machine Varieties

- High-pressure Washers: High-volume cleaning.

- Line Type Washers: Smaller batches.

- Immersion Washers: Soaking bottles.

- Spray Washers: Direct cleaning.

- Automated Systems: Efficient operation.

- Custom Solutions: Tailored to needs.

Dive deeper Paragraph:

The market offers a variety of glass bottle washing machines, each designed to cater to specific production volumes and cleaning requirements. High-pressure washers are the workhorses of high-volume operations. These machines have very high throughput and are suitable for different bottle size. on the other hand,Linear Type washers are better suited for smaller batches or operations with limited space. These machines typically feature a tunnel, It needs to put on bottles and take out bottles by manual.

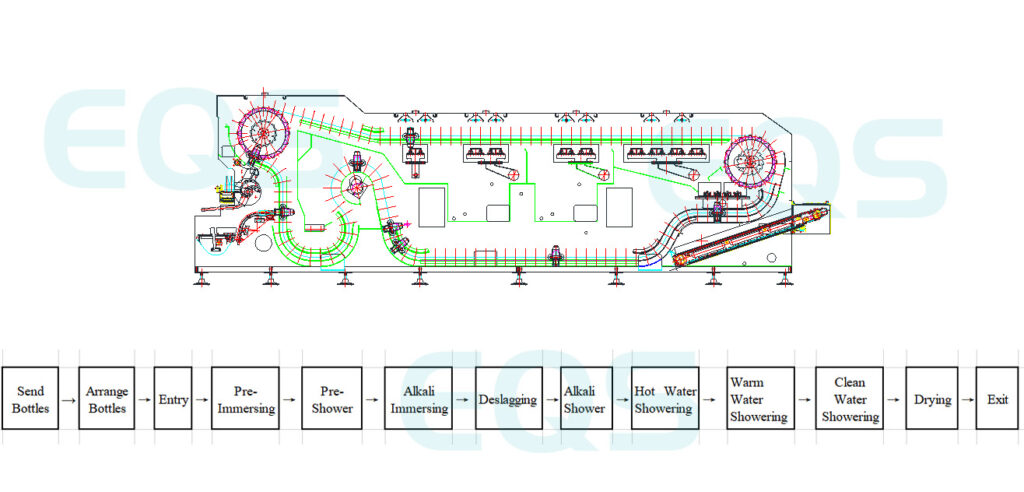

The Glass Bottle Washing Process: Step-by-Step

leading paragraph:

Behind the scenes! How do bottles get squeaky clean?

snippet paragraph:

The glass bottle washing process typically involves pre-rinsing, washing with detergent, rinsing with clean water, and sterilization. Some machines also include inspection systems to ensure bottles meet quality standards before refilling.

Cleaning Stages

- Pre-Rinsing: Removing debris.

- Detergent Wash: Cleaning thoroughly.

- Clean Water Rinse: Removing detergent.

- Sterilization: Eliminating microbes.

- Inspection: Quality control.

- Drying: Preparing for refill.

Dive deeper Paragraph:

The glass bottle washing process is a multi-stage procedure designed to ensure that bottles are thoroughly cleaned and sterilized before being refilled. The process typically begins with a pre-rinsing stage, where bottles are sprayed with water to remove any loose debris or large particles. This initial rinse helps to prepare the bottles for the more intensive cleaning stages that follow. After pre-rinsing, the bottles move to the main washing stage, where they are exposed to a detergent solution.

Key Features to Look for in a Glass Bottle Washing Machine

leading paragraph:

Smart shopping! What makes a great bottle washer?

snippet paragraph:

When choosing a glass bottle washing machine, consider factors like cleaning efficiency, water and energy consumption, ease of maintenance, and automation capabilities. Look for machines with adjustable settings and durable construction.

Must-Have Features

- Cleaning Efficiency: Thorough cleaning.

- Low Consumption: Saving resources.

- Easy Maintenance: Simple upkeep.

- Automation: Streamlined operation.

- Adjustable Settings: Customization options.

- Durable Build: Long-lasting performance.

Dive deeper Paragraph:

Selecting the right glass bottle washing machine involves careful consideration of several key features. Cleaning efficiency is paramount, as the primary purpose of the machine is to thoroughly remove contaminants and ensure that bottles are hygienic for reuse. Look for machines that offer a combination of effective washing mechanisms, such as high-pressure spray nozzles and immersion tanks, to achieve optimal cleaning results.

Maintenance and Care Tips for Glass Bottle Washing Machines

leading paragraph:

Keep it running! How to maintain your bottle washer.

snippet paragraph:

Regular maintenance is essential for glass bottle washing machines. This includes cleaning nozzles, checking water levels, inspecting belts and chains, and replacing worn parts. Proper maintenance ensures optimal performance and extends the machine's lifespan.

Maintenance Essentials

- Nozzle Cleaning: Preventing blockages.

- Water Level Checks: Ensuring proper operation.

- Belt/Chain Inspection: Maintaining movement.

- Parts Replacement: Addressing wear.

- Regular Servicing: Professional checks.

- Cleaning Schedules: Preventing buildup.

Dive deeper Paragraph:

To ensure the continued efficient and reliable operation of your glass bottle washing machine, regular maintenance is essential. Neglecting maintenance can lead to decreased cleaning performance, increased downtime, and costly repairs. One of the most important maintenance tasks is cleaning the nozzles. Over time, nozzles can become clogged with debris, mineral deposits, or detergent residue, which can disrupt the spray pattern and reduce cleaning effectiveness.

Conclusion

Investing in a quality glass bottle washing machine is a smart move for any beverage company. Keep those bottles sparkling!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.