Filling Process of the Blowing Filling Capping Combiblock

leading paragraph:

Ever wondered how bottles are made, filled, and capped all in one go? Let's find out!

snippet paragraph:

The blowing filling capping combiblock is an integrated system that combines bottle blowing, filling, and capping into a single, continuous process. This increases efficiency, reduces contamination risks, and lowers production costs for beverage manufacturers.

Transition Paragraph:

Let’s take a closer look at each stage of this fascinating process.

Stage 1: Bottle Blowing

leading paragraph:

How are plastic bottles created from raw materials?

snippet paragraph:

Bottle blowing, also known as blow molding, involves heating plastic pellets (usually PET) and injecting air into a mold. This process creates the desired bottle shape. The newly formed bottles are then transferred to the filling station.

Detailed Steps in Bottle Blowing

| Step | Description |

|---|---|

| Mold Clamping | The parison is positioned between two halves of a mold, which then close to seal the parison. |

| Air Injection | Compressed air is injected into the parison, inflating it to conform to the shape of the mold. |

| Cooling | The mold is cooled to solidify the plastic bottle. |

| Ejection | The mold opens, and the finished bottle is ejected. |

Dive deeper Paragraph:

Bottle blowing is a critical step that determines the shape and quality of the final container. In the past, beverage companies would often purchase pre-made bottles from external suppliers. However, integrating the bottle blowing process directly into the filling line offers several advantages. For example, a water bottling company in North America found that by using a combiblock system with integrated bottle blowing, they could significantly reduce their transportation costs and storage space. They also had greater control over the bottle design and quality, leading to a more consistent and appealing product. This integration not only streamlined their operations but also improved their overall efficiency and profitability.

Stage 2: Filling

leading paragraph:

How are bottles filled quickly and hygienically?

snippet paragraph:

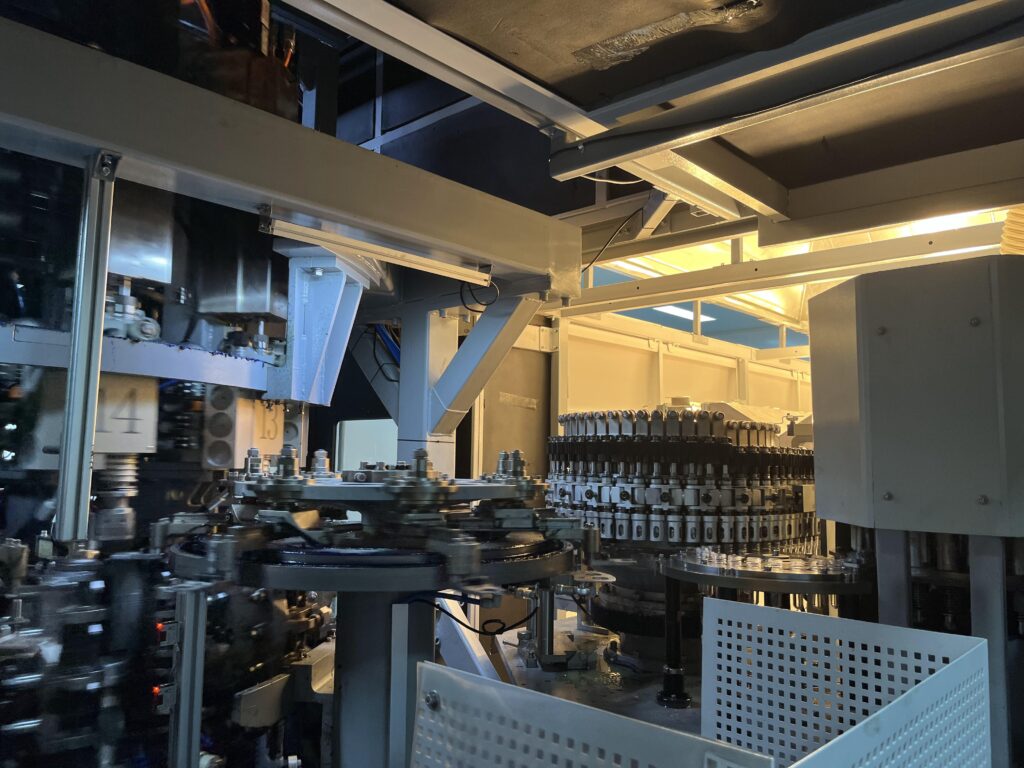

The filling stage involves transferring the beverage into the newly blown bottles. This is usually done using a rotary filling system to maximize speed and accuracy. Some products use aseptic filling technology to ensure product sterility and extend shelf life

Key Aspects of the Filling Stage

| Aspect | Description |

|---|---|

| Rotary Filling | Bottles are moved along a rotating carousel, where filling nozzles dispense the beverage into each bottle. |

| Aseptic Filling | The filling environment is sterilized to prevent contamination, ensuring the beverage remains safe and fresh. |

| Precise Dispensing | Filling nozzles are designed to deliver accurate amounts of liquid, minimizing waste and ensuring consistent fill levels. |

| No-Drip Design | Nozzles are designed to prevent dripping, maintaining a clean and hygienic filling process. |

Dive deeper Paragraph:

The filling stage is crucial for maintaining product quality and preventing spoilage. Aseptic filling is particularly important for beverages that are sensitive to microbial growth. For example, a juice producer in Europe invested in a combiblock system with advanced aseptic filling capabilities. This allowed them to produce preservative-free juices with a longer shelf life, which appealed to health-conscious consumers. The aseptic environment prevents bacteria and other microorganisms from contaminating the beverage, ensuring its safety and quality. By using a combiblock system with aseptic filling, the juice producer was able to expand their market reach and increase their brand reputation.

Stage 3: Capping

leading paragraph:

How are bottles sealed securely after filling?

snippet paragraph:

The capping stage involves placing and tightening caps onto the filled bottles. This process ensures a secure seal, preventing leaks and maintaining product freshness. Capping machines can handle various types of caps, including screw caps, snap caps, and crown caps.

Important Elements of the Capping Stage

| Element | Description |

|---|---|

| Cap Placement | Caps are accurately placed onto the bottle necks. |

| Tightening Mechanism | Caps are tightened to the correct torque to ensure a secure seal without damaging the bottle or cap. |

| Cap Sorting | Caps are sorted and oriented correctly before being placed onto the bottles. |

| Quality Control | Sensors and cameras monitor the capping process to detect and reject any improperly capped bottles. |

Dive deeper Paragraph:

The capping stage is the final step in ensuring the integrity of the packaged beverage. A secure cap prevents leaks, preserves carbonation, and protects the product from external contaminants. A soda manufacturer in Asia experienced problems with their old capping machine, which frequently resulted in loose or misaligned caps. This led to product spoilage and customer complaints. By upgrading to a combiblock system with a modern capping machine, they were able to eliminate these issues and ensure that every bottle was properly sealed. The new capping machine had advanced sensors and controls that detected and rejected any bottles with faulty caps, significantly reducing waste and improving product quality. This investment not only saved them money in the long run but also enhanced their brand image and customer satisfaction.

Conclusion

The blowing filling capping combiblock offers a seamless and efficient way to produce bottled beverages. By integrating these three processes into a single system, manufacturers can reduce costs, improve product quality, and increase their overall productivity.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.