Features of Rotary Hot Melt Glue Adhesive Labeling Machine

leading paragraph:

Want efficient labeling? Check out rotary hot melt glue machines!

snippet paragraph:

Rotary hot melt glue adhesive labeling machines are designed for continuous operation, primarily used in the washing, beverage, mineral water, and food industries. They apply rolled material labels made of OPP, pearl film, or composite paper to cylindrical bottles using hot melt adhesive. These machines offer cost savings, use environmentally friendly materials, and ensure high-speed, stable labeling with user-friendly operation.

Transition Paragraph:

Let's explore the key features that make these labeling machines so popular.

Cost Savings with OPP Film

leading paragraph:

Save money with eco-friendly labels!

snippet paragraph:

Using OPP (Oriented Polypropylene) film in rotary hot melt glue adhesive labeling machines significantly lowers production costs. OPP film and other environmentally friendly materials can reduce expenses by over 30%. This cost-effective solution makes it a smart choice for businesses looking to reduce overhead.

Cost Saving Benefits

- Reduced Material Costs: Lower price of OPP film.

- Less Adhesive Use: Efficient glue application.

- Lower Waste: Precise label placement.

- Sustainable Choice: Eco-friendly material

- Increased Profitability: Reduced expenses

Dive deeper Paragraph:

The use of OPP (Oriented Polypropylene) film in rotary hot melt glue adhesive labeling machines offers significant cost savings compared to traditional labeling methods. This cost-effective solution is a smart choice for businesses looking to reduce overhead and improve their bottom line.

Reduced Material Costs

OPP film is generally less expensive than other labeling materials, such as paper or PVC. This can result in significant cost savings, especially for businesses that label large volumes of products.

Less Adhesive Use

Hot melt glue adhesive labeling machines use only a small amount of adhesive to attach the labels to the bottles. This reduces the amount of adhesive needed, further lowering production costs.

Environmentally Friendly Materials

leading paragraph:

Good for your product, good for the planet!

snippet paragraph:

Rotary hot melt glue adhesive labeling machines support the use of environmentally friendly packaging materials, like OPP film. This aligns with the packaging industry's trend toward sustainability. Using eco-friendly materials appeals to environmentally conscious consumers and helps businesses reduce their environmental impact.

Eco-Friendly Benefits

- Recyclable Materials: Reduces environmental impact.

- Lower Carbon Footprint: Sustainable choice.

- Appeals to Consumers: Eco-conscious branding.

- Reduces Waste: Biodegradable options

- Meets Regulations: Complies with green standards

Dive deeper Paragraph:

The use of environmentally friendly materials, such as OPP film, in rotary hot melt glue adhesive labeling machines aligns with the packaging industry's trend toward sustainability. This not only helps businesses reduce their environmental impact but also appeals to environmentally conscious consumers.

Recyclable Materials

OPP film is recyclable, which means that it can be reused to make new products. This helps to reduce the amount of waste that ends up in landfills.

Lower Carbon Footprint

OPP film has a lower carbon footprint than other labeling materials, such as PVC. This means that it requires less energy to produce, which reduces greenhouse gas emissions.

Servo Motor Drive Control

leading paragraph:

Smooth and precise labeling!

snippet paragraph:

Rotary hot melt glue adhesive labeling machines use servo motor drive control for precise and reliable operation. This technology ensures accurate label placement and smooth movement, resulting in high-quality labeling. Servo motors provide better control and reduce the risk of errors.

Servo Motor Benefits

- Precise Labeling: Accurate placement.

- Smooth Movement: Consistent operation.

- Reliable Performance: Reduced downtime.

- Adjustable Speed: Optimizes labeling pace

- Energy Efficiency: Lower power consumption

Dive deeper Paragraph:

Servo motor drive control is a key feature of rotary hot melt glue adhesive labeling machines, ensuring precise and reliable operation. This technology provides better control over label placement and smooth movement, resulting in high-quality labeling.

Precise Labeling

Servo motors provide precise control over the movement of the labeling head, ensuring that labels are placed accurately on the bottles. This is essential for maintaining a consistent and professional appearance.

Smooth Movement

Servo motors provide smooth and consistent movement, which reduces the risk of errors and ensures that the labeling process runs smoothly. This helps to improve efficiency and reduce downtime.

Imported Photoelectric Eyes and PLC Human-Machine Interface

leading paragraph:

Smart technology for easy control!

snippet paragraph:

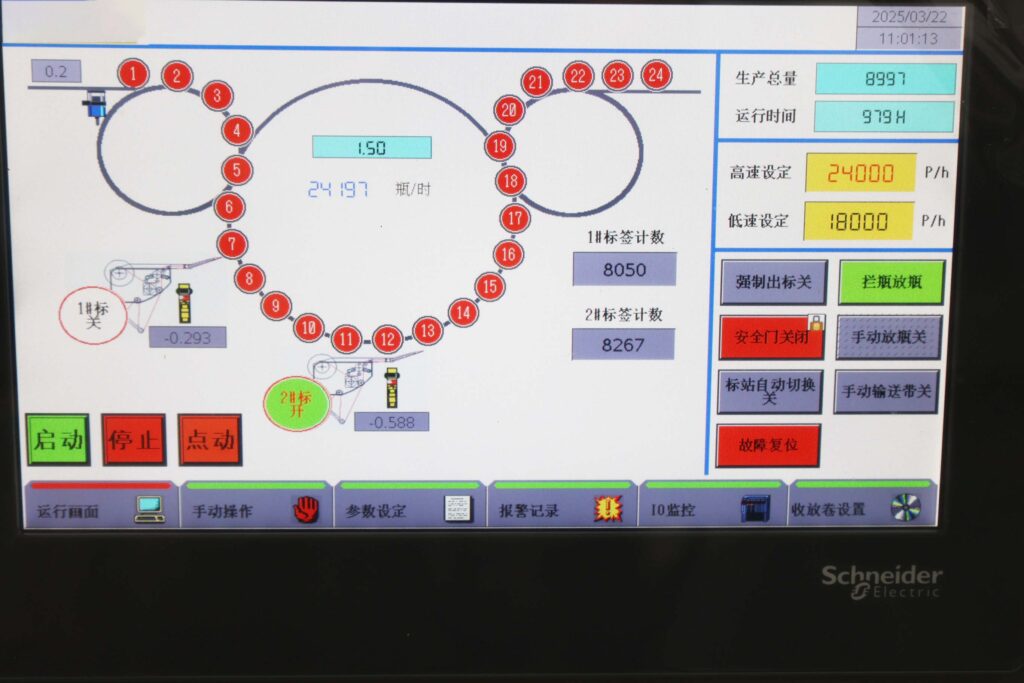

These labeling machines are equipped with photoelectric eyes imported from Japan and a PLC human-machine interface. These high-quality components enhance the machine's performance and ease of use. The PLC interface allows for simple programming and monitoring, while the photoelectric eyes ensure accurate label detection and placement.

Interface Benefits

- Easy Programming: Simple setup and adjustments.

- Accurate Detection: Reliable label placement.

- Enhanced Performance: High-quality components.

- User-Friendly: Intuitive controls

- Real-Time Monitoring: Instant status updates

Dive deeper Paragraph:

The integration of imported photoelectric eyes and a PLC (Programmable Logic Controller) human-machine interface enhances the performance and ease of use of rotary hot melt glue adhesive labeling machines. These high-quality components provide simple programming, accurate label detection, and real-time monitoring.

Easy Programming

The PLC human-machine interface allows for simple programming and adjustments, making it easy to set up and operate the machine. This reduces the learning curve and allows operators to quickly get the machine up and running.

Accurate Detection

The photoelectric eyes ensure accurate label detection and placement, preventing errors and ensuring that labels are applied correctly. This is essential for maintaining a consistent and professional appearance.

High Speed and Stable Performance

leading paragraph:

Fast and reliable labeling every time!

snippet paragraph:

Rotary hot melt glue adhesive labeling machines offer high-speed labeling with stable performance. This ensures efficient production and consistent results. The machines are designed to maintain their speed and accuracy even during continuous operation, making them ideal for high-volume production lines.

Performance Benefits

- Efficient Production: High-speed labeling.

- Consistent Results: Stable performance.

- Continuous Operation: Reliable long-term use.

- Increased Output: Maximized productivity

- Reduced Downtime: Minimal interruptions

Dive deeper Paragraph:

High speed and stable performance are critical features of rotary hot melt glue adhesive labeling machines, ensuring efficient production and consistent results. These machines are designed to maintain their speed and accuracy even during continuous operation, making them ideal for high-volume production lines.

Efficient Production

The high-speed labeling capabilities of these machines allow for efficient production, reducing the time and labor required for labeling. This helps to increase throughput and improve overall productivity.

Consistent Results

The stable performance of these machines ensures consistent results, meaning that labels are applied accurately and securely every time. This helps to maintain a consistent and professional appearance.

Conclusion

Rotary hot melt glue labeling machines are great! They save money, are eco-friendly, and label quickly and reliably.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.