Maximize Your CSD Bottling Efficiency with Advanced Filling Technology

Turnkey CSD bottling lines, incorporating European technology, with 20+ years of experience. Serving South America, Central Asia, and North America.

Your Trusted Partner in CSD Bottling Technology

Global Reach

Serving major markets worldwide

High Filling Speed

Capacity increased from 2000bph to 48000bph

Own Manufacturing

Complete quality control

COmplete Solution

Comprehensive Carbonated Soft Drink Filling Solutions

We offer a range of solutions tailored to your specific needs, from individual machines to complete turnkey lines.

Turnkey CSD Filling Lines

Advanced Carbonation Systems

Global Support & Service

Don't hesitate to contact us for more information.

jiangsu,suzhou zhangjiagang hexi rouad - china

All You Need To Know About CSD Filling Line

2.Sugar conversion system: By heating and stirring, sugar is dissolved in water to produce syrup for beverage production.

3.Degassing system: uses a vacuum pump to remove oxygen from beverages to prevent oxidation and spoilage during the filling process.

4.Cooling system: By using a cooling device to lower the temperature of the beverage, the taste and stability of the beverage are improved.

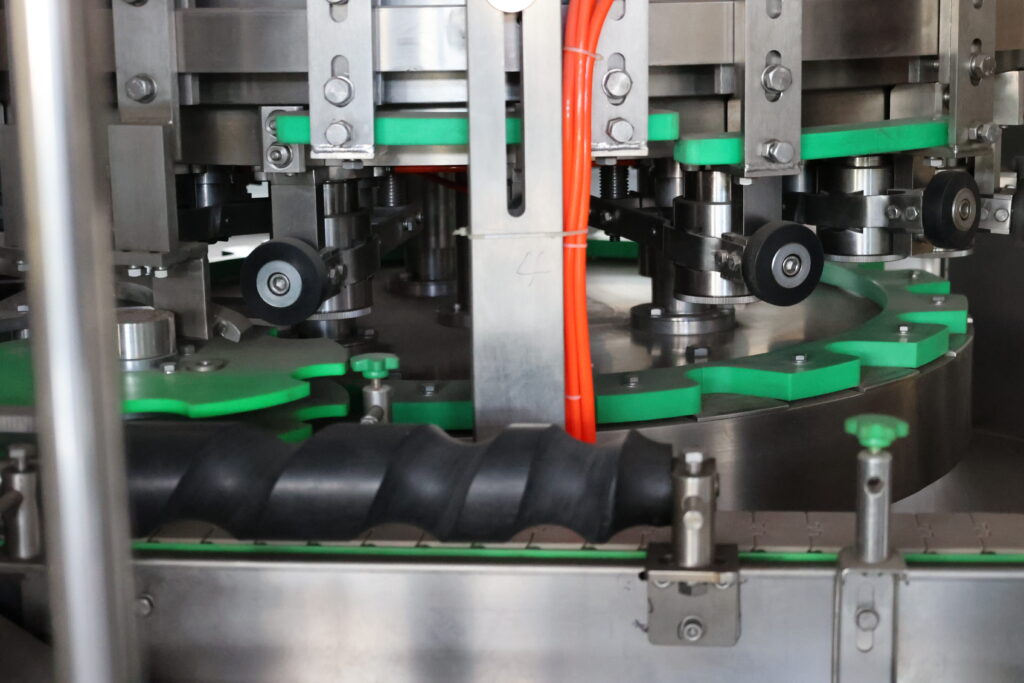

5.Filling system: This is the core part of the filling machine, which precisely controls the filling volume and speed to fill beverages into bottles.

6.Sealing system: Seal the filled beverage bottles to ensure that they will not leak during storage and transportation.

1.Mixing system: responsible for preparing syrup, mixing sugar and other ingredients in a certain proportion to form a preliminary beverage mixture

How Does CSD Filling Machine Work

PET Bottle Filling Machine

In terms of workflow, the carbonated beverage filling machine first cleans and disinfects empty bottles through automated equipment. Subsequently, the empty bottles are transported to the filling machine, which injects carbonated beverages into the bottles through a precise metering system and filling valve. During the filling process, the liquid level control device ensures that the filling amount of each bottle is consistent. After the filling is completed, the bottles are sent to the capping station, where the capping machine completes the tightening of the bottle cap. The entire process is highly automated, reducing manual intervention and improving production efficiency and product quality.

In addition, the carbonated beverage filling machine is equipped with a comprehensive detection and control system that can monitor the filling process in real time, detect and handle abnormal situations in a timely manner, thereby ensuring product consistency and safety. The maintenance and cleaning of the equipment are relatively simple, equipped with automatic cleaning function to ensure long-term stable operation of the equipment.

CSD Can Filling Machine

The filling of carbonated beverages requires special equipment, including precise temperature control, effective vibration suppression, and a comprehensive exhaust buffering system. These technologies ensure that carbonated beverages maintain their unique taste and quality during the filling process, while the entire automation process significantly improves production efficiency and ensures food safety

CSD Glass Bottle Filling Machine

The future glass bottle soda filling machine will develop towards automation, intelligence, environmental protection and energy saving, as well as diversification and personalization. For example, introducing machine vision technology to achieve automatic positioning and detection, utilizing big data and artificial intelligence for real-time monitoring and fault warning, adopting more efficient cleaning and disinfection technology to reduce resource consumption, and supporting the filling of glass bottles of different specifications and shapes, providing diverse bottle cap choices to meet constantly changing market demands.