Conveyor System

Aseptic filling technology can be applied to non-carbonated products beverage products without preservatives for long-term maintenance, high acid/low acid/neutral beverages, and PET bottle beverage products.

In water, beverage, dairy, edible oil, cosmetics production lines, the conveyor system plays an important role. How to connect the independent equipment into a proper complete line and achieve the best efficiency has a great relationship with conveyor system design.

To meet different requirements from different industries, we can provide you with high-tech full bottle conveyor systems, carton conveyors, tilting conveyors, bottle cooling tunnels, bottle warmer, cap rinser, and appendix.

The conveyor system adheres to the transmission and conveying mode in terms of structural design, adopts the modular design of the conveying unit, and the modular combination, arrangement and connection of each conveying unit are more simple and convenient, and can be more widely adapted to the personalized flat arrangement of each customer’s factory, making the installation and maintenance of the whole line of conveying production more convenient.

The side plate of the conveyor chain frame uniformly adopts 2.5mm thick 304 stainless steel brushed plate, which ensures the beauty of the outer surface and can resist the corrosion of acid and alkali. Except for the main drive shaft, the other supports and connecting fasteners are made of 304 stainless steel.

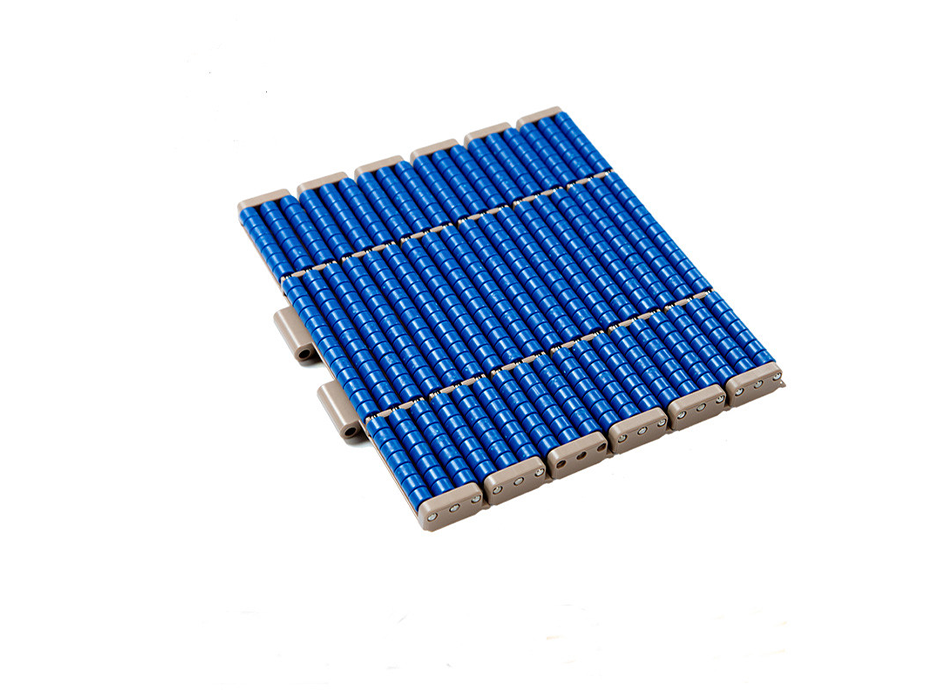

The conveyor line adopts a new type of low-friction material modular mesh plate chain as the carrier for transportation, and the transition gap between the two chain plates adjacent to the transmission is smaller than the original old structural design, and the flatness of the overall chain plate of the whole line is greatly improved. At the same time, the thickness of the chain plate is thicker than that of the traditional chain plate, which greatly improves the bearing capacity and life of the chain plate. This kind of conveyor mesh plate chain is mainly for PET or other conveyor containers that are not easy to break, which can greatly improve the smoothness of transportation.

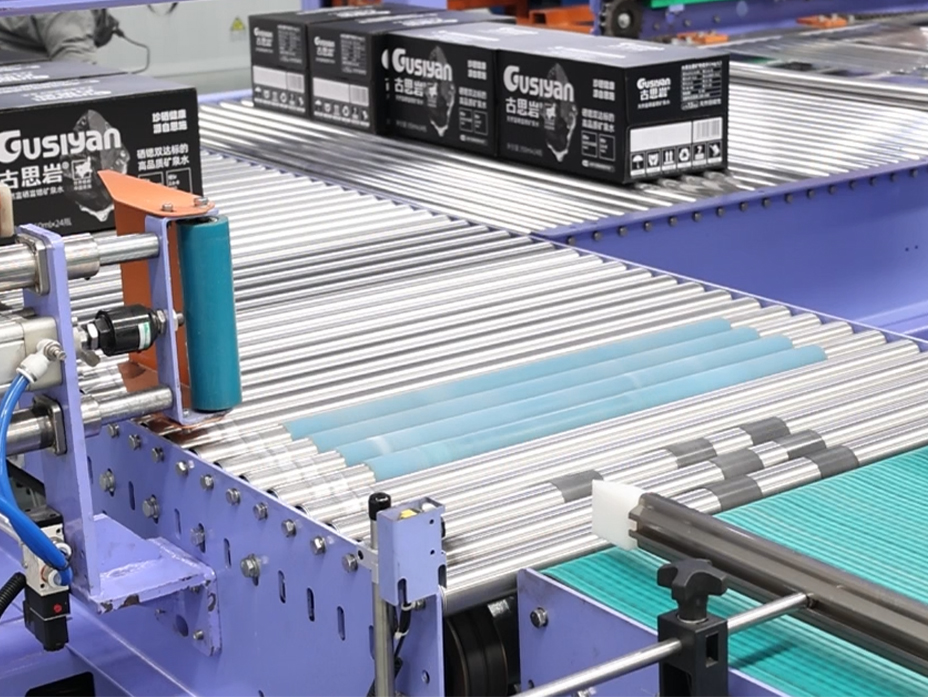

The pressure-less conveyor system is equipped for whole beverage production line, which can solve the problem of bottle squeezing, bottle jamming, bottle down.And it also equips with photoelectric detection of full bottle, bottle accumulation and the number of bottles supplied (the number of bottles supplied per unit time). According to the detected speed pulse signal, the PLC automatically synchronously tracks and changes the speed of the conveying chain to ensure continuous and non squeezing bottle supply. And it also designs with bottle down and bottle taking out devices.

The ball chain conveyor uses the standard ball chain as the carrier. By selecting the ball chain structure of different specifications and adopting different combination methods, the ball chain plate conveyor with different transmission forms, transmission widths and line speeds can be obtained, so as to meet the transmission purposes of different functional requirements and products of different specifications.

The ball chain has strong corrosion resistance, stability, and low friction, and is not easy to scratch the bottom of the conveying object. It is especially suitable for the rear transportation of various shrink films or carton packages such as various foods, beverages, PET bottles, aluminum cans, etc.

The system adopts non pressure power roller to transport cartons. The structure is a new design. The frame is formed by stamping or bending, with good rigidity and light weight. The drum is made of stainless steel, and the motor and reducer are the products of the joint venture. The transmission mode is reliable and easy to maintain.

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.