How Can Robots Help in the Food Packaging Process?

leading paragraph:

Tired of seeing human hands all over your food packaging? Robots are here to change that!

snippet paragraph:

Robots are revolutionizing the food packaging process by increasing efficiency, consistency, and hygiene. They perform tasks like picking, packing, palletizing, and cutting, ensuring food safety and reducing labor costs.

Transition Paragraph:

Let's dive into the amazing ways robots are transforming the food industry.

How Do Robots Increase Efficiency in Food Packaging?

leading paragraph:

Can robots really speed things up in the packaging world? Absolutely!

snippet paragraph:

Robots significantly increase efficiency in food packaging by working continuously without breaks, maintaining consistent speeds, and reducing downtime. This results in higher throughput and faster production cycles.

Efficiency Boost Factors

- Continuous Operation: Robots work 24/7 without breaks.

- Consistent Speed: No slowdowns or fatigue.

- Reduced Downtime: Fewer errors and maintenance.

- Optimized workflows: Improving production.

- High throughput: Increasing production.

- Accuracy: Minimizing mistakes.

Dive deeper Paragraph:

Robots bring unparalleled efficiency to food packaging lines by operating continuously around the clock, without the need for breaks or rest. Unlike human workers who may experience fatigue and reduced performance over time, robots maintain consistent speeds and accuracy throughout their shifts, ensuring a steady and reliable output. This continuous operation and consistent speed translate to higher throughput and faster production cycles, allowing food manufacturers to package more products in less time. Additionally, robots are less prone to errors and require less downtime for maintenance compared to human workers, further contributing to their superior efficiency in food packaging.

How Do Robots Ensure Consistency in Food Packaging?

leading paragraph:

Are robots better at doing the same thing over and over? You bet!

snippet paragraph:

Robots ensure consistency in food packaging by performing repetitive tasks with precision, following programmed instructions exactly, and minimizing variations in packaging quality. This leads to uniform product presentation and reduces errors.

Consistency Assurance Factors

- Precise Movements: Robots follow programmed paths exactly.

- Repetitive Tasks: Robots excel at doing the same thing repeatedly.

- Minimal Variation: Reduced errors in packaging quality.

- Uniform presentation: Consistent product.

- Standardized processes: Minimizing human error.

- Quality control: Maintaining high standards.

Dive deeper Paragraph:

Robots excel at performing repetitive tasks with unparalleled precision, making them ideal for ensuring consistency in food packaging. Unlike human workers who may experience variations in their performance due to fatigue or distractions, robots follow programmed instructions exactly, executing each task with the same level of accuracy and consistency every time. This leads to minimal variations in packaging quality, ensuring that each product is presented uniformly and meets the required standards. By eliminating human error and maintaining consistent processes, robots help food manufacturers achieve a higher level of quality control and deliver products that consistently meet customer expectations.

How Do Robots Improve Hygiene in Food Packaging?

leading paragraph:

Can robots make our food packaging cleaner? Absolutely!

snippet paragraph:

Robots improve hygiene in food packaging by minimizing human contact with food products, reducing the risk of contamination. They can be easily sterilized and operated in controlled environments, ensuring a cleaner packaging process.

Hygiene Enhancement Factors

- Reduced Human Contact: Less chance of contamination.

- Easy Sterilization: Robots can be easily cleaned.

- Controlled Environments: Sterile operating conditions.

- Food safety: Minimizing health risks.

- Cleanliness: Maintaining hygienic standards.

- Compliance: Meeting regulatory requirements.

Dive deeper Paragraph:

Robots significantly enhance hygiene in food packaging by minimizing human contact with food products, thereby reducing the risk of contamination. Unlike human workers who may carry bacteria or pathogens on their hands or clothing, robots can be easily sterilized and operated in controlled environments, such as cleanrooms, to maintain a high level of cleanliness. The use of robots in food packaging helps to ensure that products are handled in a hygienic manner, minimizing the potential for foodborne illnesses and enhancing consumer safety. By reducing human contact and maintaining strict cleanliness standards, robots contribute to a safer and more hygienic food supply chain.

What Tasks Can Robots Perform in Food Packaging?

leading paragraph:

What exactly can these robots do in a food factory?

snippet paragraph:

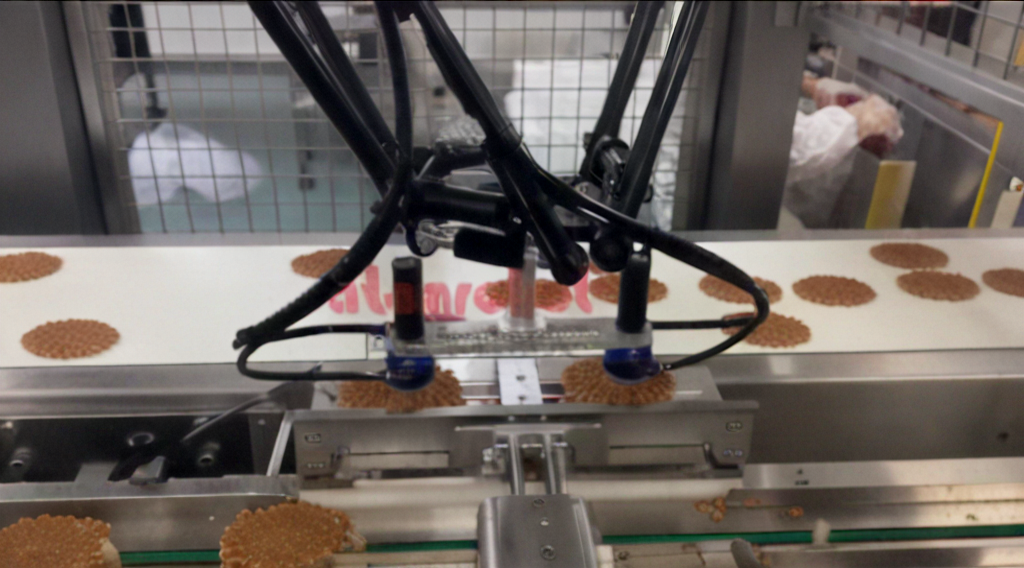

Robots can perform a variety of tasks in food packaging, including picking and placing items, packing products into containers, palletizing boxes, cutting food items, and even quality control inspections using vision systems.

Robot Task Capabilities

- Picking and Placing: Handling individual food items.

- Packing: Filling containers with products.

- Palletizing: Stacking boxes on pallets.

- Cutting: Portioning food items.

- Quality control: Inspecting products for defects.

- Sorting: Categorizing products based on criteria.

Dive deeper Paragraph:

Robots are capable of performing a wide range of tasks in food packaging, making them versatile assets in modern food processing facilities. They can be programmed to pick and place individual food items, such as fruits, vegetables, or baked goods, with precision and speed. Robots can also pack products into containers, whether it's filling boxes with snacks, sealing bags of chips, or wrapping sandwiches. Furthermore, robots can be used to palletize boxes, stacking them neatly and securely on pallets for efficient transportation. Some robots are even equipped with cutting tools to portion food items, such as slicing cheese or dicing vegetables. In addition to these physical tasks, robots can also be used for quality control inspections, using vision systems to detect defects or inconsistencies in food products or packaging.

How Do Robots Reduce Labor Costs in Food Packaging?

leading paragraph:

Can robots really save food companies money? Absolutely!

snippet paragraph:

Robots reduce labor costs in food packaging by automating tasks that would otherwise require human workers, decreasing the need for large workforces, and minimizing expenses related to wages, benefits, and training.

Labor Cost Reduction Factors

- Automation: Replacing human workers with robots.

- Reduced Workforce: Fewer employees needed.

- Lower Expenses: Less spending on wages and benefits.

- Minimized Training: Reduced training costs.

- Increased productivity: Improving profits.

- Long-term savings: Lower operational costs.

Dive deeper Paragraph:

Robots offer significant labor cost savings in food packaging by automating tasks that would typically require human workers. By deploying robots to handle picking, packing, palletizing, and other repetitive tasks, food manufacturers can reduce the size of their workforce, decreasing the need for large teams of employees. This reduction in workforce translates to lower expenses related to wages, benefits, and training, resulting in substantial cost savings over time. While the initial investment in robotic automation may be significant, the long-term operational cost savings and increased productivity make it a worthwhile investment for many food companies.

Conclusion

Robots are revolutionizing food packaging, making it faster, cleaner, and more efficient. It's a win-win for businesses and consumers!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.