Bottle Molding Machine

A bottle blowing machine heats plastic preforms (PET/PP) and shapes them into containers like water bottles, beverage bottles, and cosmetic packaging for food, beverage, pharmaceutical, and cosmetics industries.

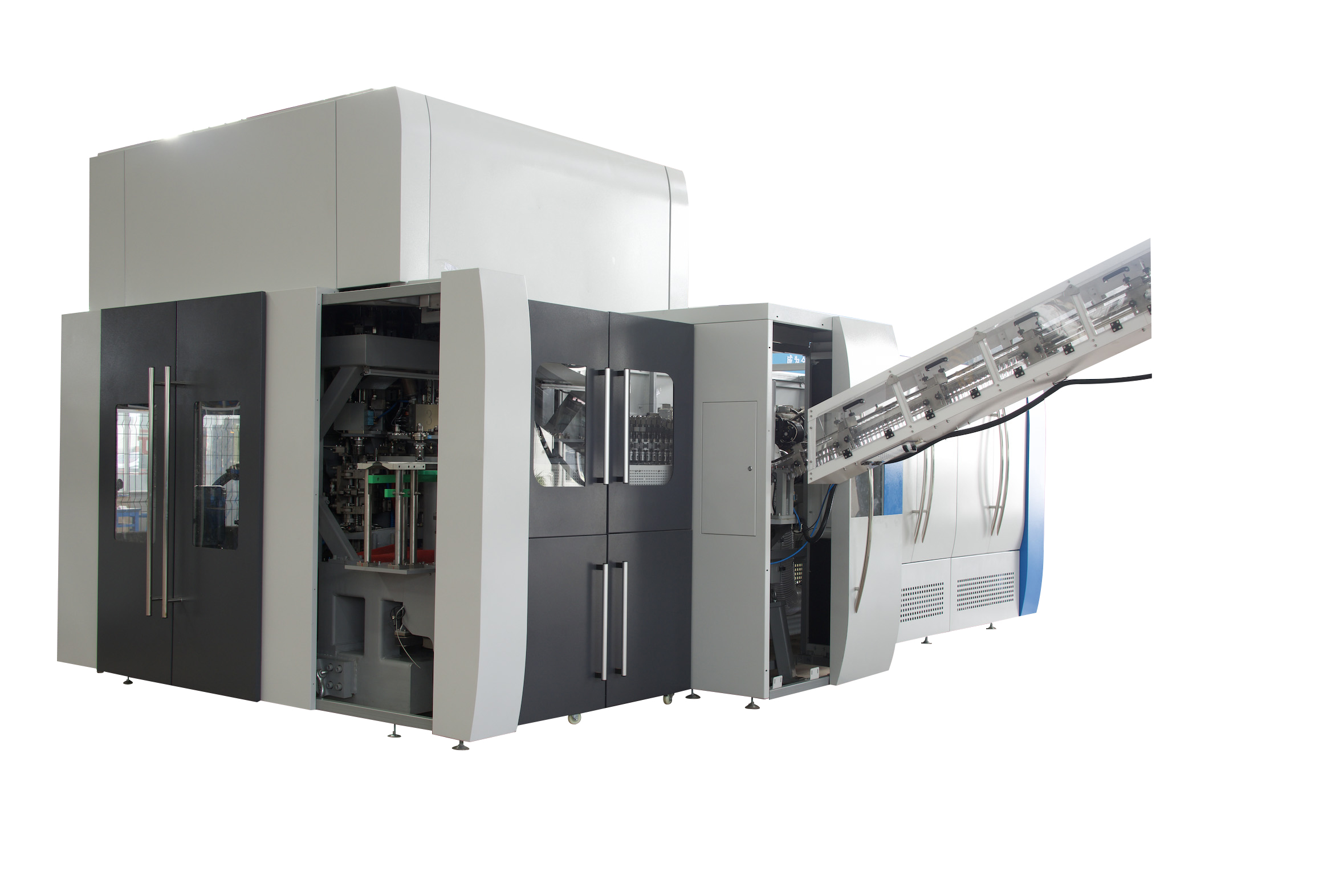

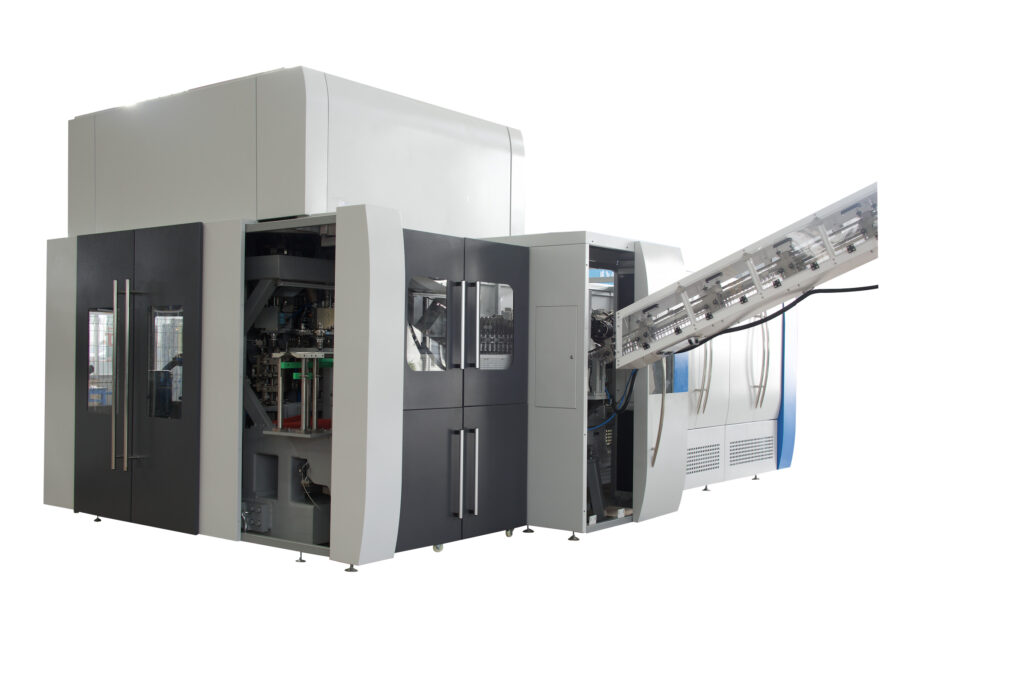

EQS rotary blow molding machine heats PET preforms and shapes them with compressed air into bottles, meeting high-speed production demands. Its fully automatic design, featuring advanced automation and energy efficiency, is widely adopted by beverage manufacturers for producing PET containers for drinks, dairy, condiments, and more.

With industry-leading technology, EQS uses Haas CNC machining for precision bottle design. The machine delivers high stability, intelligence, and reliability, catering to diverse sectors like pharmaceuticals, cosmetics, and food packaging.

Wide range of applications

beverages, milk products, wines, condiments, medicines, daily chemicals, etc.

The advantages of EQS PET blow molding machine

The high-speed rotary full-automatic bottle blowing machine produced by our company adopts the control system composed of SIMATIC HMI (man-machine interface), Siemens S7 Series industrial control system (PLC system) and relevant control detection and actuator. The whole machine is stable, reliable and rapid response.

The operation interface is intuitive and easy to understand, which is used to adjust and control the equipment There are two modes: production mode and commissioning mode, which can facilitate production, inspection and maintenance The on-off heating and time (angle) adjustment of the equipment can be carried out through 36 programmable function keys (28 with LED) contained in the SIMATIC HMI (man-machine interface) operation panel. The equipment adopts a fully enclosed mode, and the whole process does not need manual contact, so that the products can better meet the hygienic standards required by food, beverage and medical packaging.

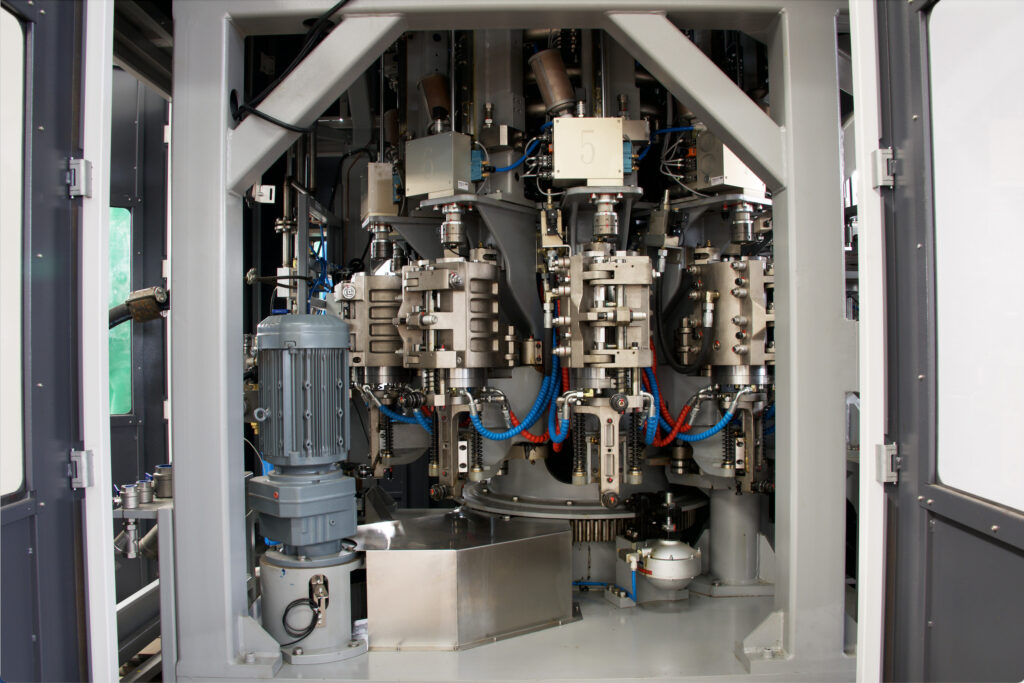

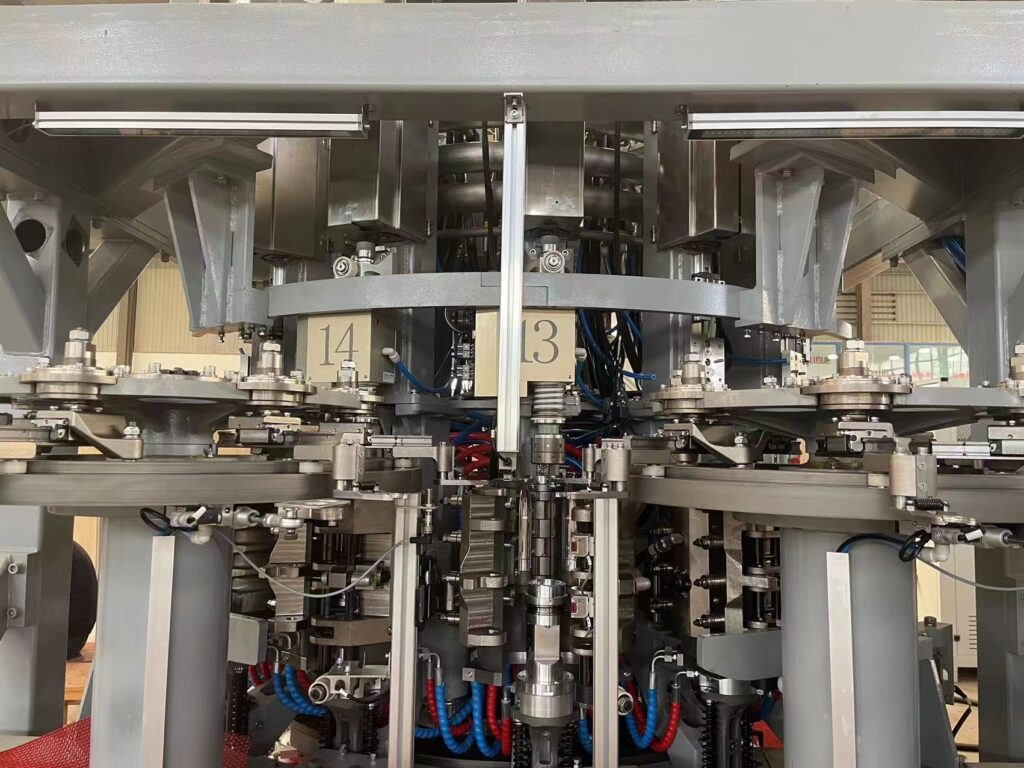

Each torque point and key point of the machine is provided with torque protector, photoelectric protection switch, travel protection switch and other protection measures, so as to ensure the safe operation of the equipment and avoid the forced operation of the robot, so as to prolong the service life of the machine and the maintenance cost of accessories.

With CE certification system, the safety of operation people and machine are strictly in accordance with the requirements of CE certification.

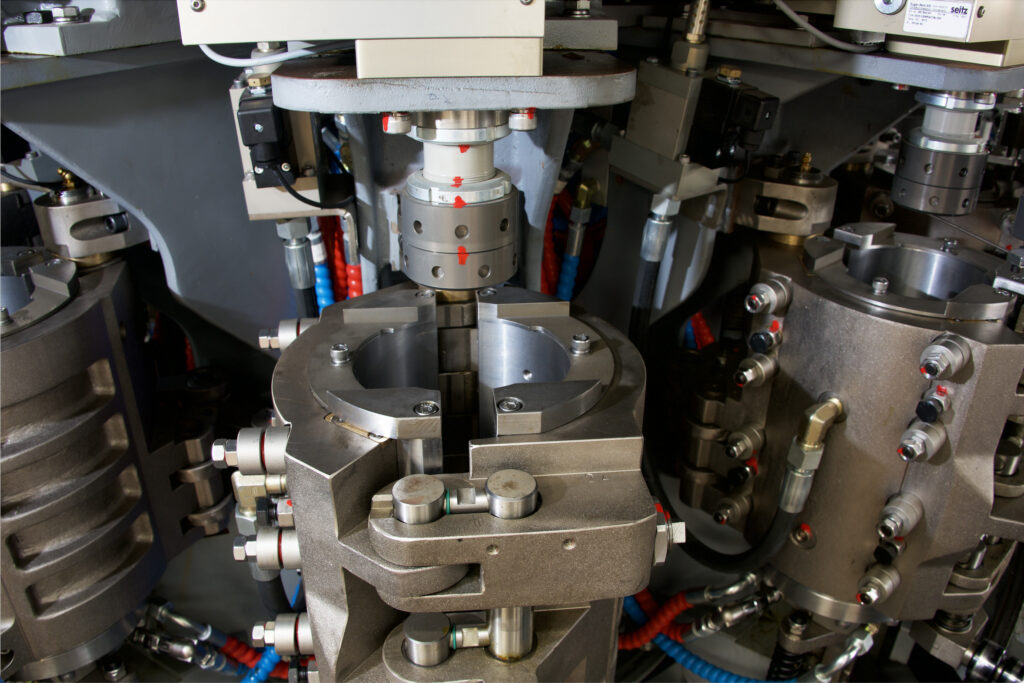

High quality products from famous foreign manufacturers (OPTEX, FESTO, Seitz, Oki, etc.) are selected for key components such as equipment detection, cylinder, solenoid valve and bearing, which makes the performance of the whole machine more stable and reliable, reduces fault shutdown and maintenance costs, so as to ensure high production efficiency and yield and reduce production costs.

Product Series:

- Standard Series: Bottle Size 0.25-2.5L

- Single Serve Series: Bottle Size ≤0.77L

- Large Series: Bottle Size 3-19L

- Aseptic PET Series

Single Cavity Capacity:

- Water Bottles: 2500 BPH (Bottles Per Hour)

- CSD (Carbonated Soft Drink) Bottles: 2000 BPH

- Hot Fill Bottles: 1200 BPH

Don't hesitate to contact us for more information.

jiangsu,suzhou zhangjiagang hexi rouad - china

The working principles of EQS blow molding machine

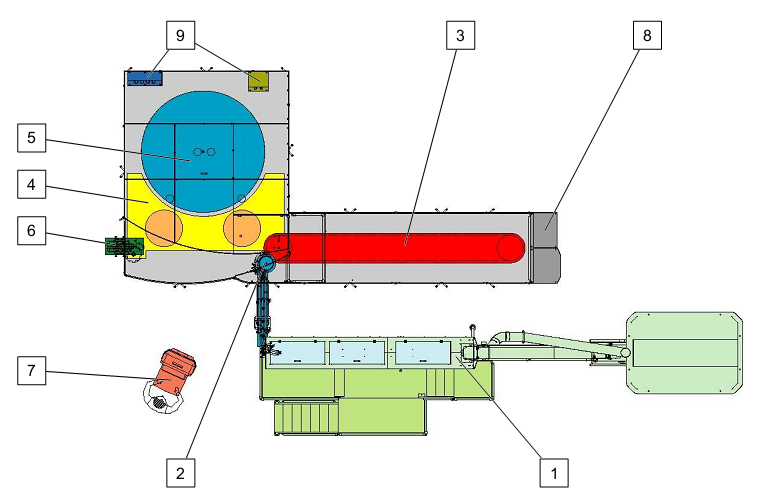

Equipment Components

1- Feeding Device

2- Star Wheel

3- PET Preform Heating Furnace

4- PET Preform Transfer Tray

5- Main Turntable

6- Bottle Outlet

7- Control System

8- Main Control Cabinet

9- Gas and Water Connect Port

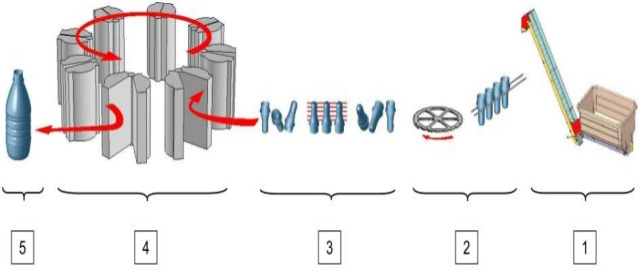

Blowing Processing

1- Batch bottle preforms are lifted and placed at the inlet of the bottle blowing machine

2- Bottle preforms are sent to the bottle blowing machine

3- Bottle preforms are heated and adjusted

4- Bottle preform are blown in mold

5- Finished bottles are sent out from the bottle blowing machine

EQS Blow Molding Machine Specifications

| Feature | Specification |

|---|---|

| Bottle Type | PET bottles, used in the packaging of water, juice, carbonated beverages, edible oil, soy sauce, daily cosmetics, and so on. |

| Single Mold Capacity |

|

| Bottle Size | 0.25L - 20L |

| Bottle Variety |

|

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.