BFC Combiblock Machine

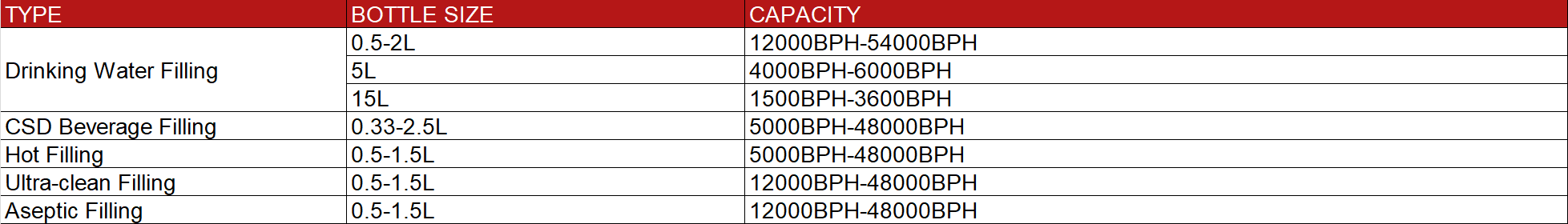

Technical data

Driven by the continuous improvement of living standards, consumers are increasingly aware of the importance of healthy drinking water. From cooking to tea preparation, more and more individuals are choosing bottled and barreled water, leading to a consistent rise in sales for large-capacity packaged water.

However, the barreled water market has traditionally adhered to a single product model.

Recognizing the existing challenges and pain points within the barreled water industry, EQS, a leader in technological innovation, is the first to introduce disposable PET material to the market. We have successfully tailored production lines for disposable barreled drinking water for numerous clients, including a 12L line for Nongfu Spring and a 15L line for Robust.

Our production lines offer compatibility with a range of capacities from 5L to 19L and utilize a precise Gravimetric Flow Meter with Photoelectric Detection for filling. The production capacity spans from 1200 bottles per hour (BPH) to 4800 BPH.

The Blowing-Filling-Capping Combiblock for CSD beverages represents an innovative integration of blowing, filling, and capping technologies. By implementing a synchronized servo system, it achieves seamless control across multiple integrated units, streamlining production for a variety of beverage types. This advanced system significantly reduces investment costs, energy consumption, and maintenance expenses. Furthermore, its optimized layout contributes to a remarkable energy consumption reduction of up to 25%.

The PHS Blowing Unit is engineered to produce PET bottles capable of holding dissolved CO2 liquid up to 4.2 times its volume.

The PHS CSD Beverage Filling Unit, developed with extensive experience in carbonated soft drink filling, ensures stable filling, prevents frothing, and maintains uniform fill levels. When paired with our CSD mixer, this Combiblock can fill CSD beverages at high speeds and with exceptional stability, ultimately delivering high-quality taste for beverage manufacturers.

Our esteemed customer base includes industry leaders such as Coca-Cola, Pepsi, Jianli Bao (YUANQI SENLIN), and Arctic Ocean.

Filling Method: Mechanical Valve Filling, Flow Meter Filling, Electronic Valve Filling

Capacity: 12,000 BPH – 48,000 BPH

Filling Temperature: 0-4°C or 12-15°C

Suitable Beverages: Soda Water, Sparkling Water, Cocktail, Flavored Water…

This versatile machine is primarily designed for filling and packaging PET bottles containing a wide range of beverages, including Juice, Tea Drinks, Energy Drinks, Functional Beverages, and more.

Capacity: 9,000 BPH – 48,000 BPH