Intelligent Warehouse Solutions

Empowering businesses with comprehensive smart factory solutions through integrated automation and intelligent systems

Our Comprehensive Services

Lean Planning

Strategic optimization of manufacturing processes to eliminate waste and maximize efficiency

Management Information Software

Advanced software solutions for seamless integration and control of manufacturing operations

Integrated System Implementation

Unified control of supply chain, storage, production, and logistics systems

Hardware Device Control

Comprehensive control of automated equipment including cranes, AGVs, and robots

Logistics Automation

Streamlined movement of goods with automated conveyor and sorting systems

Operational Execution

Precise control and monitoring of all automated systems and processes

The Power of Integration

📦

Supply Chain & Storage

Optimize inventory management and material flow with intelligent storage solutions

- ✔ Reduced labor costs

- ✔ Improved space utilization

- ✔ Real-time inventory tracking

⚙

Production Processes

Streamline manufacturing with automated systems and smart controls

- ✔ Enhanced productivity

- ✔ Consistent quality

- ✔ Reduced downtime

🚚

Logistics & Distribution

Efficient movement of goods throughout your facility

- ✔ Faster order fulfillment

- ✔ Accurate tracking

- ✔ Optimized routes

Don't hesitate to contact us for more information.

jiangsu,suzhou zhangjiagang hexi rouad - china

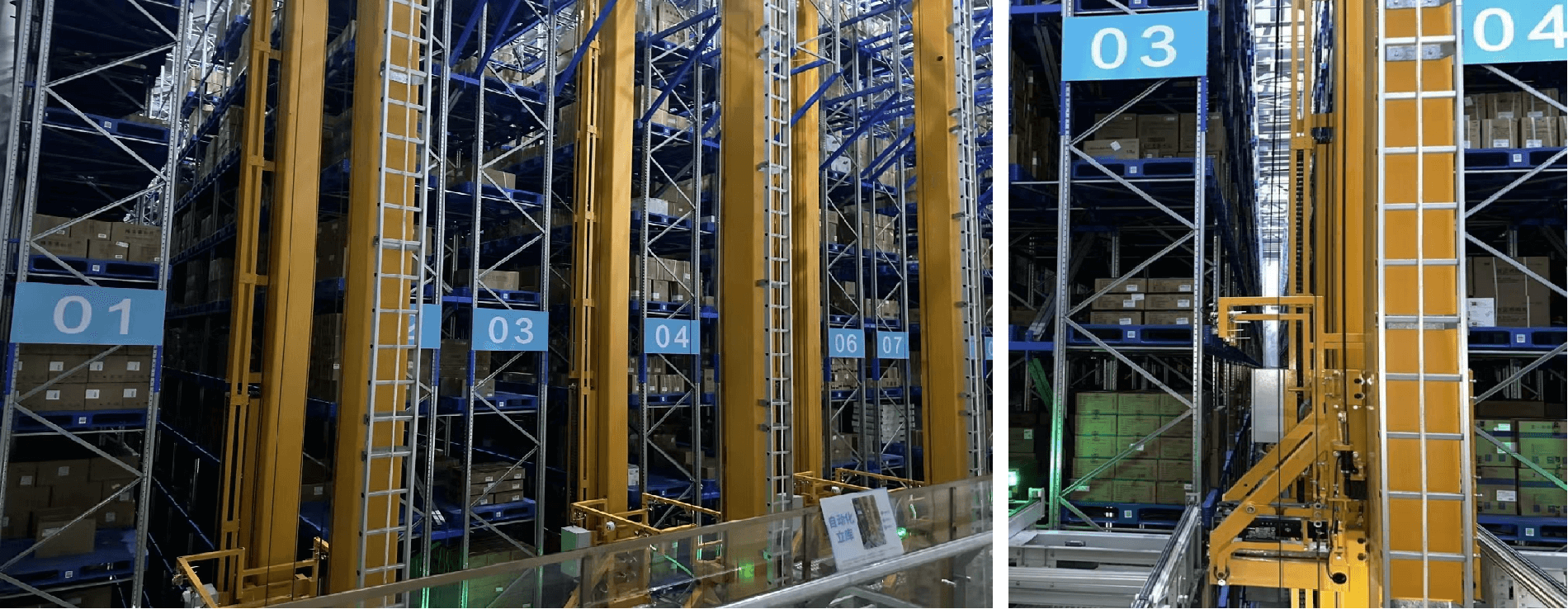

Industry applications of ASRS

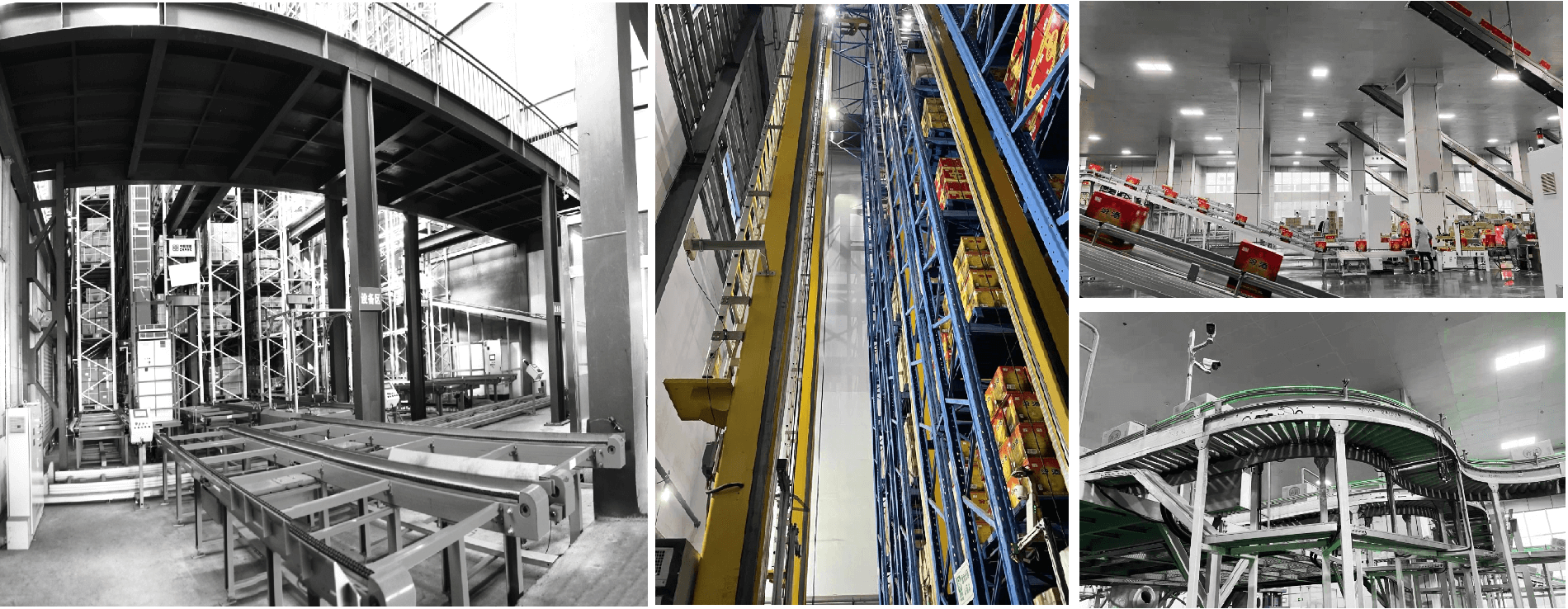

Wine

Project Description:

16 28-meter-high aisles, 16 double-deep stackers, storage capacity of 40,802 pallets; full-process box and pallet logistics system in the warehouse area of 7,630 square meters;

EQS Supply Scope:

Stackers, racking, conveyors, WMS, WCS;

Implementation Period:

Total period of 180 days, design and manufacturing of 60 days, on-site installation of 65 days, single-machine debugging of 35 days, joint debugging of 20 days;

Project Benefits:

Space utilization increased by 70%, inventory and delivery efficiency increased from 170 pallets/hour to 370 pallets/hour, 13 in-plant logistics personnel reduced, and 31 warehouse operation personnel reduced.

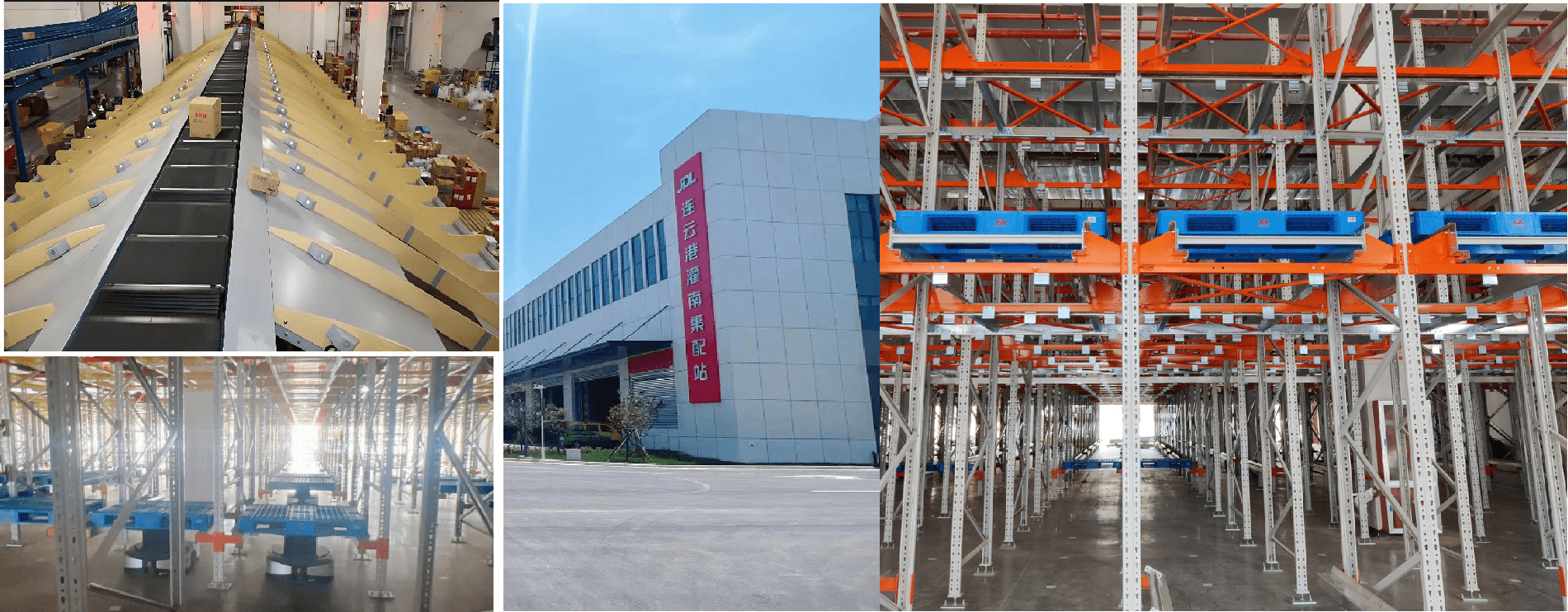

Logistics Cold Chain

Project Description:

10.2-meter-high four-directional trolley intensive storage (-25°C cold storage), 16 four-directional trolleys, storage capacity of 5,326 trays, warehouse area of 3,500 square meters;

Supply Scope Of EQS:

Four-directional trolleys, racking, conveyors, WMS, WCS, AGI system, cross-belt sorter;

Implementation Period:

Total period of 145 days, design and manufacturing of 50 days, on-site installation of 40 days, single-machine debugging of 20 days, joint debugging of 25 days;

Project Benefits:

Space utilization increased by 20%, 13 in-plant logistics personnel reduced, and 46 warehouse operation personnel reduced (picking operation personnel).

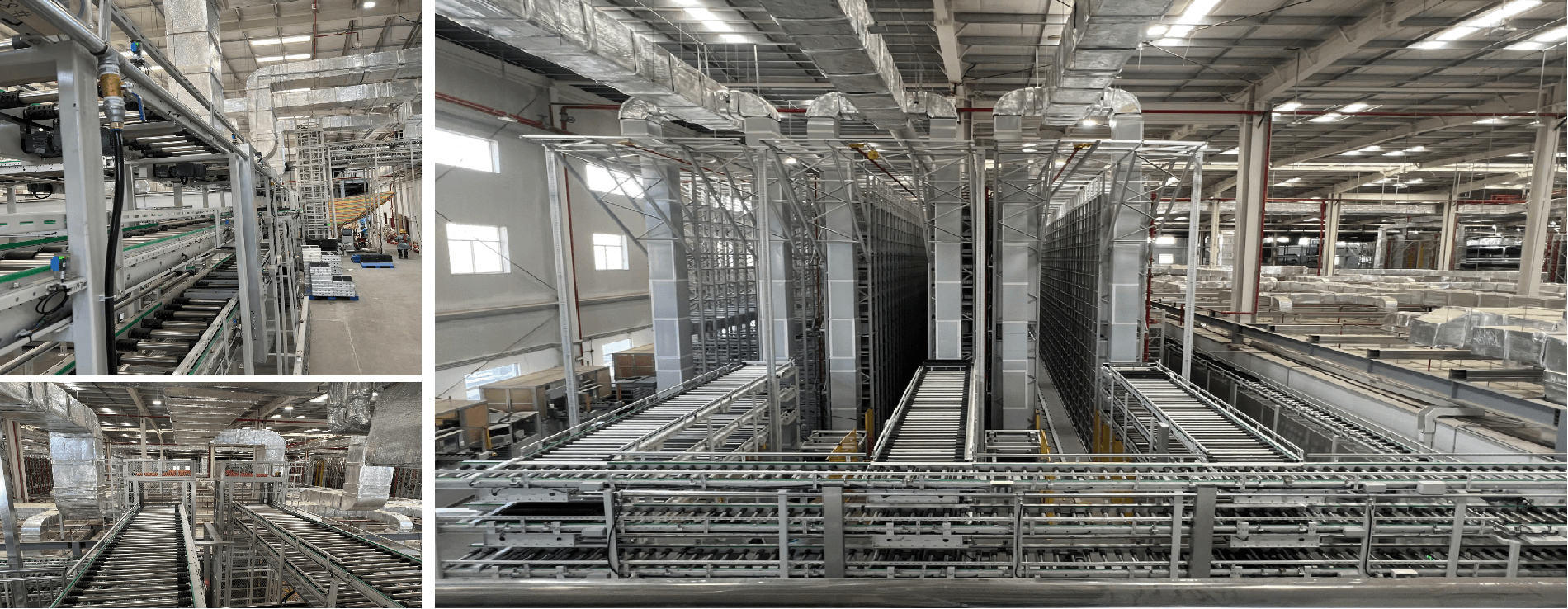

New Energy Vehicles

Project Description:

12 independent and different functional 3D warehouses, each with 4 single-deep stackers, totaling 48 stackers, battery tray storage capacity of 6,784 trays, and warehouse area of 4,320 square meters;

EQS Supply Scope:

28 stackers for 7 warehouses, 7 warehouses' shelves, and an 8.4 kilometer conveying system for the whole process;

Implementation Cycle:

Total period of 265 days, design and manufacturing of 80 days, on-site installation of 75 days, single machine debugging of 50 days, and joint debugging of 60 days;

Project Benefits:

The space utilization rate has increased by 30%, and a total of 68 logistics personnel in the factory have been reduced.

Pharmaceutical

Project Description:

8 21-meter-high aisles, 5 double-deep stacker cranes, 3 single-deep stacker cranes, storage capacity of 17,054 pallets, warehouse area of 4,160 square meters;

EQS Supply Scope:

Stacker cranes, racking, conveyors, WMS, WCS;

Implementation Period:

Total period of 165 days, design and manufacturing of 50 days, on-site installation of 60 days, single-machine debugging of 35 days, joint debugging of 20 days;

Project Benefits:

Space utilization increased by 40%, inventory and delivery efficiency increased from 165 pallets/hour to 280 pallets/hour, 8 in-plant logistics personnel reduced, and 16 warehouse operation personnel reduced.

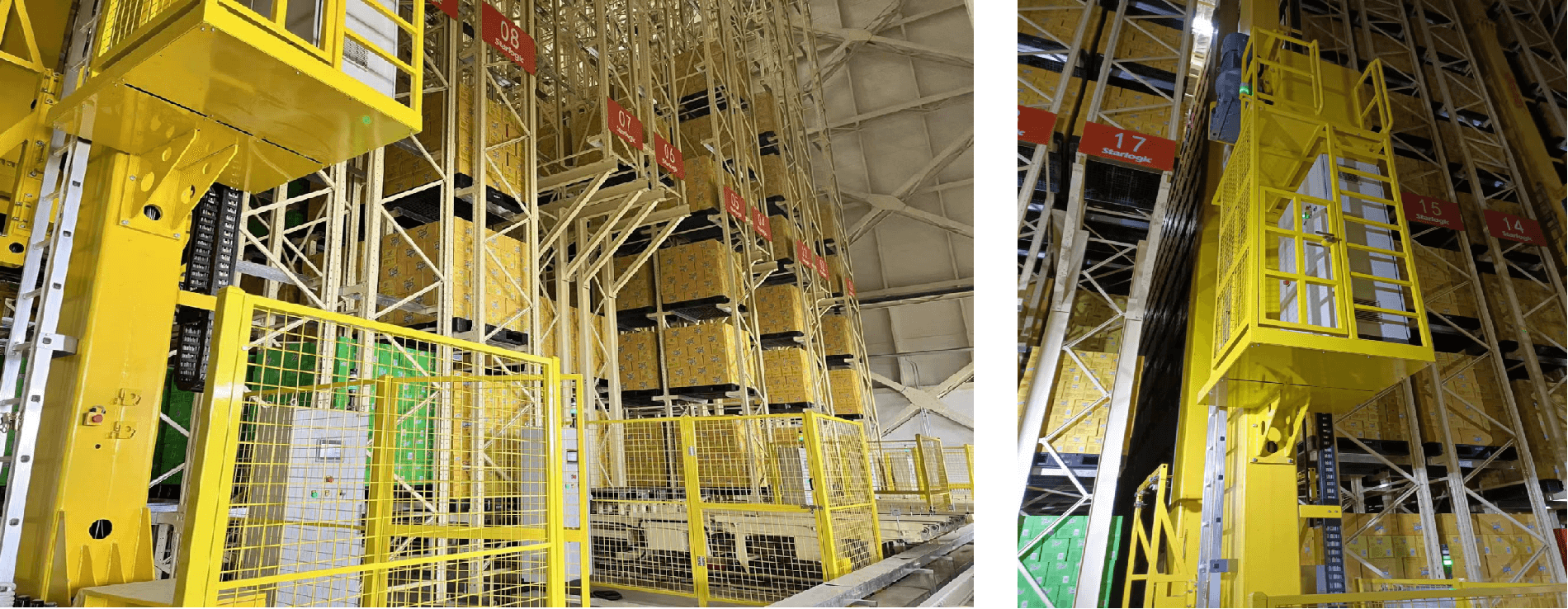

Beverages

Project Description:

10 21-meter-high aisles, 8 double-deep stacker cranes, 2 single-deep stacker cranes, storage capacity of 21,048 pallets, warehouse area of 5,040 square meters;

EQS Supply Scope:

Stacker cranes, racking, conveyors, WMS, WCS;

Implementation Period:

Total period of 180 days, design and manufacturing of 60 days, on-site installation of 65 days, single-machine debugging of 35 days, joint debugging of 20 days;

Project Benefits:

Space utilization increased by 50%, inventory and delivery efficiency increased from 150 pallets/hour to 320 pallets/hour, 11 in-plant logistics personnel reduced, and 25 warehouse operation personnel reduced.

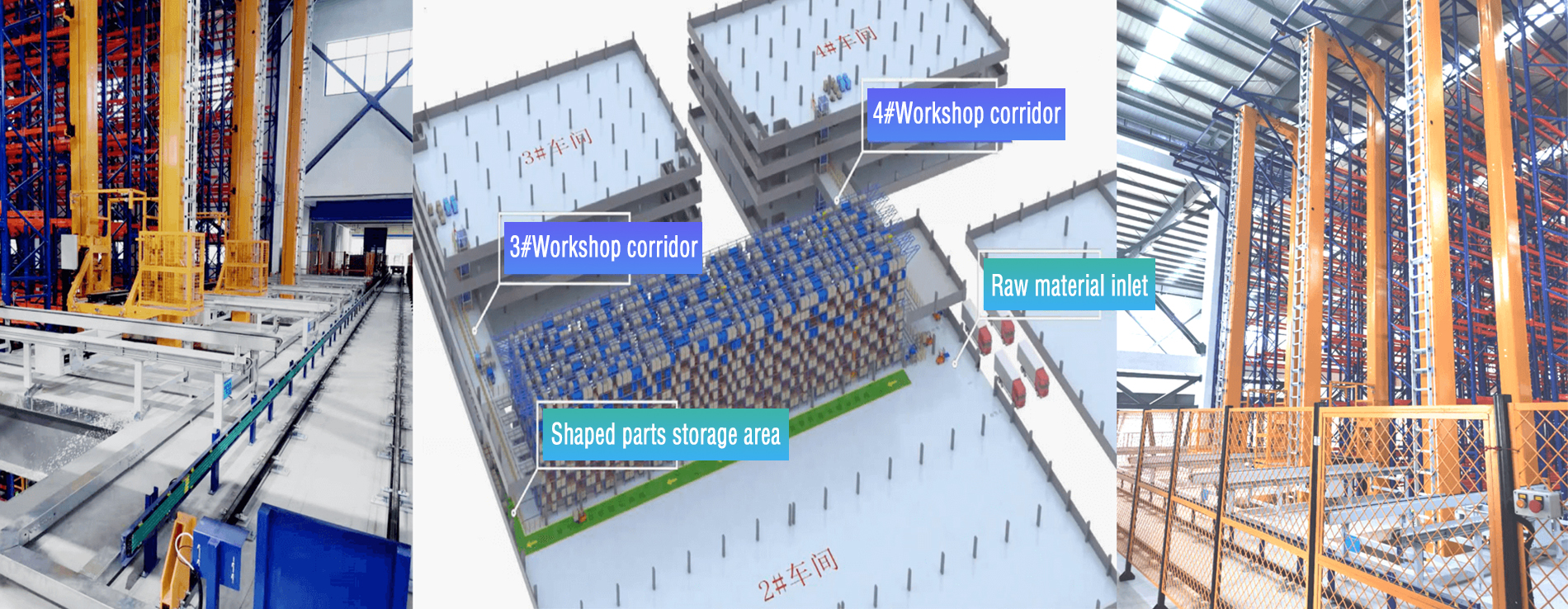

Smart Home

Project Description:

5 21-meter-high aisles, 5 single-deep stacker cranes, storage capacity of 7,990 large racks, and a warehouse area of 2,670 square meters;

EQS Supply Scope:

Stacker cranes, racking, conveyors, RGV, hoists, IWMS, WCS;

Implementation Period:

Total period of 160 days, design and manufacturing of 50 days, on-site installation of 60 days, single-machine debugging of 30 days, joint debugging of 20 days;

Project Benefits:

Space utilization increased by 60%, inventory turnover rate from 130 trays/hour to 210 trays/hour, with a reduction of 13 logistics personnel in the factory and 16 warehouse operation personnel.

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.