How to Choose the Right Mineral Water Filling Machine?

Leading paragraph:

Starting a mineral water business? The right filling machine is crucial for success!

Snippet paragraph:

Choosing the right mineral water filling machine depends on your production capacity, budget, and the reliability of the manufacturer. Assess your market size to determine the needed capacity and find a machine that fits your budget. Partnering with a reputable manufacturer ensures quality and support.

Transition Paragraph:

Let's explore the key factors to consider when selecting a mineral water filling machine for your business.

What Production Capacity Do You Need?

Leading paragraph:

Matching your machine's output to your market demand is essential for efficiency.

Snippet paragraph:

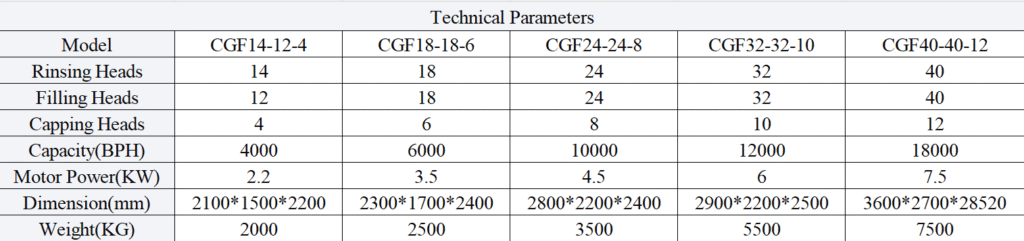

Determine your required production capacity by analyzing your market size and projected sales. Small businesses might start with a capacity of 2,000 to 4,000 bottles per hour (BPH). Larger operations may need 10,000 BPH or more. Choose a machine that meets your current needs and allows for future expansion.

Dive deeper Paragraph:

Here's a breakdown to help you decide:

Small-Scale Operations (2,000 - 4,000 BPH)

If you're just starting out or serving a local market, a machine with a capacity of 2,000 to 4,000 bottles per hour might be sufficient. These machines are typically more affordable and easier to operate. They are suitable for businesses with limited capital and lower production demands.

Medium-Scale Operations (4,000 - 10,000 BPH)

For businesses serving regional markets or experiencing steady growth, a machine with a capacity of 4,000 to 10,000 bottles per hour is a good choice. These machines offer a balance between production speed and cost-effectiveness. They can handle increased demand while remaining relatively manageable.

Large-Scale Operations (10,000+ BPH)

If you're targeting a large market or have significant distribution channels, you'll need a high-capacity machine capable of filling 10,000 bottles per hour or more. These machines are typically fully automated and require a larger investment. However, they provide the efficiency and output needed to meet high demand.

I once advised a client to start with a smaller machine, even though they were ambitious. It allowed them to test the market and scale up later without overspending initially. It turned out to be a wise decision!

What Types of Filling Machines Are Available?

Leading paragraph:

Different filling setups offer various advantages for mineral water bottling.

Snippet paragraph:

Mineral water filling machines come in two main types: rinse-fill-cap (washing, filling, and capping in one machine) and blow-fill-cap (bottle blowing, filling, and capping in one machine). Rinse-fill-cap machines are suitable for pre-made bottles. Blow-fill-cap machines create bottles from PET preforms. Choose based on your bottle production needs.

Dive deeper Paragraph:

Let's compare these options:

Rinse-Fill-Cap Machines

Rinse-fill-cap machines combine bottle rinsing, filling, and capping into one integrated system. These machines are ideal for operations that purchase pre-made bottles. They streamline the filling process and reduce the need for separate equipment.

Blow-Fill-Cap Machines

Blow-fill-cap machines integrate bottle blowing, filling, and capping into a single machine. These machines start with PET preforms, which are then blown into bottles before being filled and capped. Blow-fill-cap machines are suitable for businesses that want to produce their own bottles on-site.

The blow-fill-cap is great because you are making the bottles yourself. However, the cost will be higher.Suitable for high-capacity.

What Level of Automation Do You Need?

Leading paragraph:

Automation can significantly boost your production efficiency, but it also impacts your budget.

Snippet paragraph:

Consider your labor costs and production goals when determining the level of automation. Semi-automatic machines require manual loading and unloading. Fully automatic machines automate the entire filling process. While automated systems require a larger investment, they reduce labor costs and increase output.

Dive deeper Paragraph:

Let's break down the automation levels:

Semi-Automatic Machines

Semi-automatic machines require operators to manually load and unload bottles. They offer a lower initial investment but higher labor costs. These machines are suitable for small-scale operations with limited budgets.

Fully Automatic Machines

Fully automatic machines automate the entire filling process, from loading to capping. They require a higher initial investment but lower labor costs. These machines are ideal for large-scale operations seeking maximum efficiency.

How Important Is the Manufacturer's Reputation and Support?

Leading paragraph:

Choosing a reliable manufacturer ensures you get a quality machine and ongoing support.

Snippet paragraph:

Select a manufacturer with a proven track record of producing reliable filling machines. Look for positive customer reviews and testimonials. Ensure the manufacturer offers comprehensive after-sales support, including installation, training, and maintenance services. A reputable manufacturer provides peace of mind and helps minimize downtime.

Dive deeper Paragraph:

Here's what to look for:

Proven Track Record

A manufacturer with a long history of producing quality filling machines is more likely to deliver a reliable product. Look for companies with experience in the mineral water industry. Check their customer references and case studies to assess their expertise.

Positive Customer Reviews

Read online reviews and testimonials to get a sense of the manufacturer's reputation. Pay attention to comments about the machine's performance, reliability, and ease of use. Look for consistent themes in the reviews to get an accurate picture.

Comprehensive After-Sales Support

Ensure the manufacturer offers comprehensive after-sales support, including installation, training, and maintenance services. A good manufacturer will provide assistance with setting up the machine, training your staff, and troubleshooting any issues that may arise.

Spare Parts Availability

Check that the manufacturer offers readily available spare parts. Quick access to spare parts is essential for minimizing downtime in case of breakdowns. A reliable manufacturer will maintain a stock of spare parts and offer fast shipping.

I always tell my clients, "Don't just buy a machine, buy a relationship." The support you get after the sale is just as important as the machine itself.

Conclusion

Selecting the right mineral water filling machine requires careful consideration of your production needs, budget, and the manufacturer's reputation. By evaluating these factors, you can make an informed decision and invest in a machine that will help you achieve your business goals.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.