In the bustling world of manufacturing and packaging, oil filling machines stand as pillars of efficiency and precision. Whether it's the delicate process of bottling gourmet olive oil or the robust filling of engine oil, these machines are designed to meet the demands of various industries. The rotary electronic weighing filling and capping machine is a new generation of high-speed filling/capping machine developed by Guangzhou Machinery Co., Ltd. using the most advanced technology. This article will explain to you the advantages of EQS oil tank filling machinery.

Process flow and main features

1.Screw bottle feeding

The screw is used to make the distance between the conveyed bottles equal and synchronized with the distance between the bottles in the star wheel drive. The conveying screw drive has a torque limit, and the equipment stops in time to avoid damage when there is a bottle inversion or jamming.

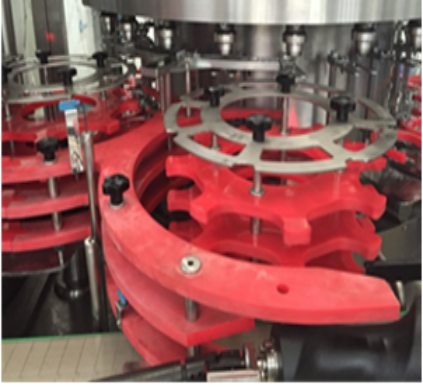

2.Intermediate star wheel

Middle star wheel: A high molecular polyethylene bottle-pulling star wheel is used, and the overall bottle-holding bottom conveying method is adopted; When changing bottle shapes, the entire star wheel is replaced, and the handle replacement method is very convenient and quick.

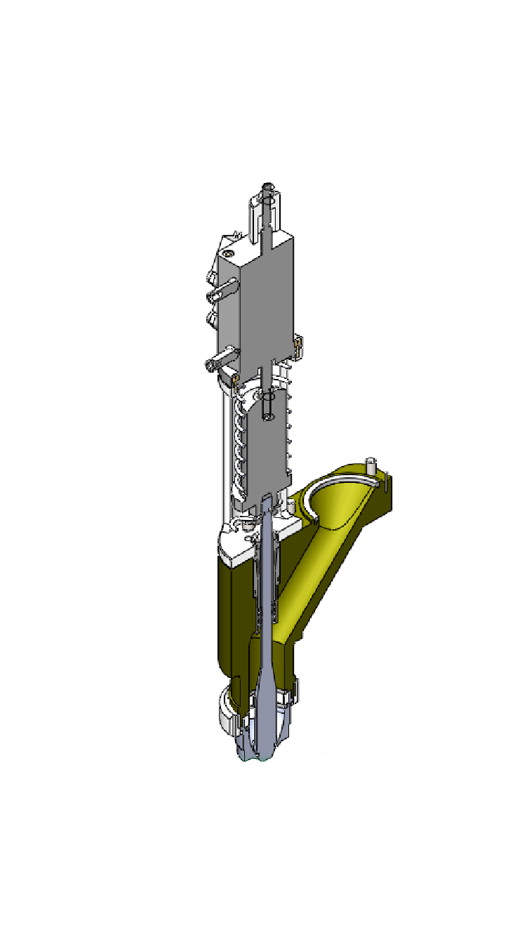

3.Filling Parts

It uses a weighing filling method with high filling accuracy, and the valve opening is controlled in two stages: coarse filling - fine filling - valve closing.

The valve is controlled by two cylinders, and the mode of the filling process can be changed arbitrarily to ensure that the filling flow rate meets the requirements and the product is filled to the required weight in a short time. It is convenient to adjust the flow during the filling process, the filling efficiency is effectively improved, and at the same time, it solves the common problems of domestic oil filling valves: oil spills when opening and closing the valve, oil dripping after closing the valve, and excessive error in product weight. This valve, when used in conjunction with a weighing sensor, provides precise weight control, resulting in a weight error of ± 2 grams for the filled product, reaching the advanced level both domestically and internationally.

The filling machine is equipped with an automatic lifting device, which automatically lifts to the appropriate position when draining oil or changing bottle type-related parts.

The bottle-related parts of the filling machine are fixed by handle, making it convenient to change and adjust the bottle type.

4.Capping Parts

The guide rail travel is long, and the double-column fastening method ensures the equipment is firmly fixed with little vibration, high cap concentricity, and cap defect rate ≤ 0.2%;

The cap drop guide rail is equipped with a mechanism to prevent reverse cap passage and reverse cap removal, and a set of photoelectric switches will automatically stop the machine when there is no cap on the cap drop guide rail, which can effectively prevent the appearance of no cap bottles;

The capping machine is equipped with a bottle feeding detection switch, which is interlocked with the cap locking cylinder at the connection point of the cap rail and the cap pan to control the cap discharge, ensuring that the cap feeding stops when there is no bottle or the filling accuracy does not meet the requirements, reducing the cap loss;

The high-efficiency inclined hopper centrifugal cap arrangement method reduces cap wear and the probability of reverse cap;

The cap aligner is equipped with a missing cap detection mechanism to control the start and stop of the cap lift.

5.FIlling Valve

Patented design of the filling valve, the filling valve has a large calibre and is directly connected with the filling barrel. The filling valve has a large calibre and is directly connected with the filling barrel, which makes the filling speed fast, rejects dripping and splashing and reduces. Reduce pipeline resistance loss and the possibility of food contamination.

The filling valve is a spring-loaded normally closed valve, which will not produce valve in the absence of power and air pressure. The filling valve is a spring-loaded normally closed valve, which will not leak under both power and air pressure, and the higher the pressure is, the more the filling valve will be closed. The valve closes tightly.

Two levels of coarse and fine filling, smooth adjustment, high filling accuracy; With HBM intelligent digital weighing module, the filling weight is automatically optimized and calibrated to ensure continuous high-precision filling requirements and simply achieve conversion between different oil products and filling volumes; It does not fill when the weight of the packaging container exceeds the tolerance, and it also has leak-proof function.