Aseptic Filling Systems for Milk Beverages in PET Bottles

leading paragraph:

Keeping milk fresh and safe! Let's explore aseptic filling for milk in PET bottles.

snippet paragraph:

Aseptic filling systems for milk beverages in PET bottles ensure the product is sterile and free from contaminants. The process involves sterilizing both the milk and the PET bottle before filling and sealing in a sterile environment, extending shelf life without refrigeration.

Transition Paragraph:

Let's dive into the details of this critical process!

Sterilization of Milk: Eliminating Microorganisms

leading paragraph:

How do they ensure the milk is completely free of bacteria?

snippet paragraph:

Milk is sterilized using ultra-high temperature (UHT) processing, which involves heating the milk to a high temperature (e.g., 135-150°C) for a short period (e.g., 2-5 seconds) to kill microorganisms while preserving its nutritional value.

UHT Process Details

- High-Temperature Heating: Kills bacteria and spores.

- Short Duration: Minimizes heat damage.

- Rapid Cooling: Preserves milk quality.

- Continuous Flow: Efficient processing.

- Heat Exchangers: Precise temperature control.

- Quality Monitoring: Ensuring effectiveness.

Dive deeper Paragraph:

The sterilization of milk is a critical step in the aseptic filling process, as it ensures that the milk is completely free of microorganisms that could cause spoilage or pose a health risk to consumers. Ultra-high temperature (UHT) processing is the most common method used to sterilize milk for aseptic filling. This process involves heating the milk to a high temperature, typically between 135°C and 150°C, for a short period of time, usually between 2 and 5 seconds. This rapid heating and cooling effectively kills bacteria and spores while minimizing the impact on the milk's nutritional value and flavor.

Sterilization of PET Bottles: Ensuring Container Safety

leading paragraph:

What about the bottles themselves? How are they sterilized?

snippet paragraph:

PET bottles are sterilized using various methods, including chemical sterilization with peracetic acid or hydrogen peroxide, UV radiation, or heat sterilization. These methods eliminate any microorganisms on the bottle surface, ensuring a sterile container for the milk.

Sterilization Techniques for PET Bottles

- Chemical Sterilization: Using peracetic acid or hydrogen peroxide.

- UV Radiation: Disinfecting the bottle surface.

- Heat Sterilization: Applying high temperatures.

- Rinsing Systems: Removing sterilizing agents.

- Air Filtration: Maintaining sterile environment.

- Automated Monitoring: Ensuring effectiveness.

Dive deeper Paragraph:

In addition to sterilizing the milk, it is also essential to sterilize the PET bottles to ensure that they are free from microorganisms that could contaminate the milk during the filling process. Various methods are used to sterilize PET bottles, including chemical sterilization, UV radiation, and heat sterilization. Chemical sterilization typically involves using peracetic acid or hydrogen peroxide to kill any microorganisms on the bottle surface. The bottles are then rinsed with sterile water to remove any residual chemicals.

Aseptic Filling Process: Maintaining Sterility

leading paragraph:

How do they fill the bottles without reintroducing contamination?

snippet paragraph:

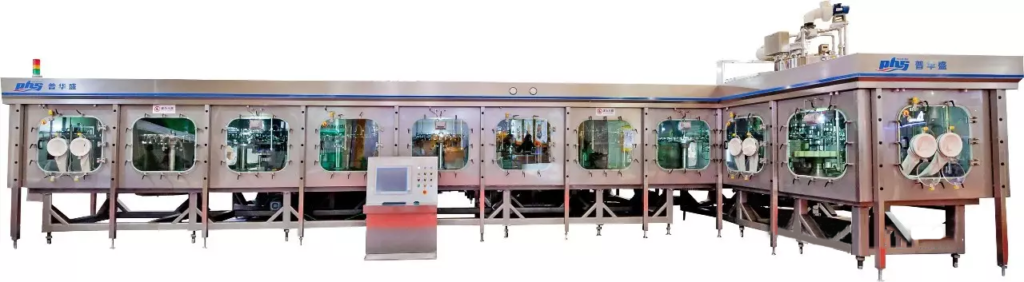

The aseptic filling process occurs in a sterile environment, often within a closed chamber with HEPA-filtered air. Sterilized milk is filled into sterilized PET bottles, and then the bottles are immediately sealed to prevent any contamination.

Key Elements of Aseptic Filling

- Sterile Environment: Closed chamber with HEPA filters.

- HEPA-Filtered Air: Removing airborne particles.

- Automated Filling: Minimizing human contact.

- Sealed System: Preventing contamination.

- Continuous Monitoring: Ensuring sterility.

- Regular Sanitization: Maintaining a clean environment.

Dive deeper Paragraph:

The aseptic filling process is the heart of the system, and it must be carried out in a completely sterile environment to prevent any contamination of the milk. This is typically achieved by performing the filling process within a closed chamber that is equipped with HEPA filters to remove airborne particles and maintain a sterile atmosphere. The sterilized milk is then filled into the sterilized PET bottles using automated filling machines that minimize human contact and reduce the risk of contamination.

Sealing and Capping: Ensuring a Tight Closure

leading paragraph:

How do they seal the bottles to guarantee freshness?

snippet paragraph:

After filling, the PET bottles are immediately sealed with sterilized caps or closures. These caps provide a tight barrier against external contaminants, ensuring the milk remains sterile and fresh throughout its shelf life.

Sealing and Capping Technologies

- Sterilized Caps: Ensuring hygiene.

- Tight Seals: Preventing contamination.

- Automated Application: Consistent sealing.

- Induction Sealing: Creating a hermetic seal.

- Tamper-Evident Features: Ensuring product integrity.

- Quality Checks: Verifying seal integrity.

Dive deeper Paragraph:

Once the PET bottles have been filled with sterilized milk, they are immediately sealed with sterilized caps or closures to prevent any post-filling contamination. These caps provide a tight barrier against external contaminants, ensuring that the milk remains sterile and fresh throughout its shelf life. The sealing and capping process is typically automated to ensure consistent and reliable application of the caps.

Benefits of Aseptic Filling

leading paragraph:

Why use aseptic filling for milk in PET bottles?

snippet paragraph:

Aseptic filling offers several benefits, including extended shelf life without refrigeration, preservation of nutritional value and flavor, reduced use of preservatives, and the ability to distribute milk to remote locations without cold chain infrastructure.

Key Advantages

- Extended Shelf Life: No refrigeration needed.

- Preserved Nutrition: Minimal heat damage.

- Reduced Preservatives: Natural product.

- Wide Distribution: Reaching remote areas.

- Cost Savings: Lower transportation costs.

- Environmentally Friendly: Reduced energy consumption.

Dive deeper Paragraph:

Aseptic filling offers numerous benefits for milk producers and consumers alike. One of the most significant advantages is the extended shelf life of the milk, which can be several months without the need for refrigeration. This is particularly beneficial for distributing milk to remote locations or regions where cold chain infrastructure is limited.

Conclusion

Aseptic filling is a game-changer for milk in PET bottles! It's all about safety, freshness, and convenience, bringing quality milk to more people, further away!

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.