Juice Production Line Secrets: Inside the Bottling Process

leading paragraph:

Ever wonder how your favorite juice gets from the fruit to the bottle? Let's spill the secrets!

snippet paragraph:

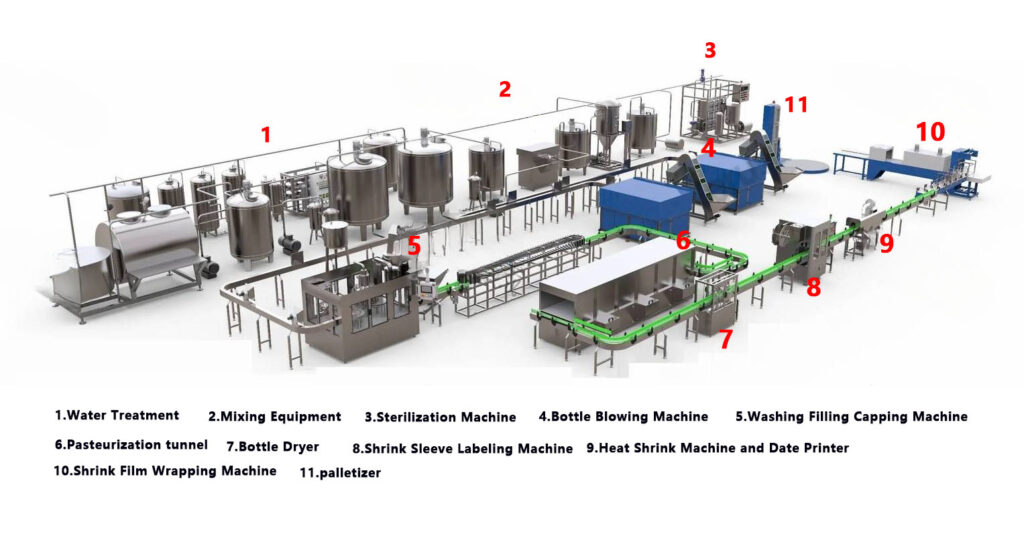

The juice bottling process includes juice extraction, pasteurization, filling, capping, labeling, and packaging. Modern factories use advanced technology and automation to ensure efficiency and maintain juice quality.

Transition Paragraph:

Let's explore each step of this fascinating process!

Juice Extraction: The First Step

leading paragraph:

Where does all that delicious juice come from?

snippet paragraph:

Juice extraction involves squeezing or pressing fruits to obtain the juice. Different methods, like cold-pressing or centrifugal extraction, are used depending on the type of fruit and desired juice quality.

Extraction Methods

- Cold-Pressing: Preserves nutrients and flavor.

- Centrifugal Extraction: Efficient for large-scale production.

- Enzymatic Treatment: Increasing juice yield.

- Pulp Removal: Clarifying the juice.

- Filtration Systems: Removing solids.

- Quality Control: Ensuring juice purity.

Dive deeper Paragraph:

The juice extraction stage is the foundation of the entire bottling process. It involves carefully extracting the juice from the selected fruits while preserving their natural flavors, nutrients, and quality. Different extraction methods are employed depending on the type of fruit being processed and the desired characteristics of the final juice product. Cold-pressing is a popular method for producing high-quality juices, as it minimizes heat exposure and oxidation, thereby preserving the delicate flavors and nutrients of the fruit.

Pasteurization Ensuring Safety

leading paragraph:

How do they keep the juice safe to drink?

snippet paragraph:

Pasteurization is a heat treatment process that eliminates harmful microorganisms and extends the shelf life of the juice. It involves heating the juice to a specific temperature for a set time, then quickly cooling it.

Key Aspects of Pasteurization

- Heat Treatment: Kills harmful bacteria.

- Extended Shelf Life: Prevents spoilage.

- Temperature Control: Precise heating to preserve flavor.

- Flash Pasteurization: Rapid heating and cooling.

- Tunnel Pasteurization: Bottles are heated and cooled.

- Quality Checks: Ensuring effectiveness.

Dive deeper Paragraph:

Pasteurization is a critical step in the juice bottling process, as it ensures the safety and extends the shelf life of the final product. This heat treatment process eliminates harmful microorganisms, such as bacteria, yeasts, and molds, that could cause spoilage or pose a health risk to consumers. The pasteurization process involves heating the juice to a specific temperature for a predetermined amount of time, and then quickly cooling it down. The specific temperature and duration of the heat treatment depend on the type of juice and the target microorganisms.

Filling: Precision is Key

leading paragraph:

How do they get the right amount of juice into each bottle?

snippet paragraph:

The filling stage involves accurately dispensing the pasteurized juice into sterilized bottles. Advanced filling machines use volumetric or gravimetric methods to ensure precise filling levels and minimize spillage.

Filling Methods

- Volumetric Filling: Dispenses a specific volume of juice.

- Gravimetric Filling: Measures the weight of the juice.

- Sterile Filling: Maintaining hygiene.

- Automated Systems: High-speed filling.

- No-Drip Nozzles: Preventing spills.

- Quality Checks: Ensuring accuracy.

Dive deeper Paragraph:

The filling stage is a crucial step in the juice bottling process, as it ensures that each bottle receives the correct amount of juice while maintaining the highest levels of hygiene and product quality. Advanced filling machines are employed to accurately dispense the pasteurized juice into sterilized bottles, utilizing either volumetric or gravimetric methods. Volumetric filling involves dispensing a specific volume of juice into each bottle, ensuring consistent fill levels.

Capping: Sealing the Freshness

leading paragraph:

How do they seal the bottles to keep the juice fresh?

snippet paragraph:

Capping involves securely sealing the filled bottles with caps or closures to prevent contamination and maintain freshness. Automated capping machines ensure tight seals and consistent application.

Capping Technologies

- Automated Capping Machines: High-speed sealing.

- Tight Seals: Prevents contamination.

- Cap Sterilization: Ensuring hygiene.

- Torque Control: Preventing over-tightening.

- Cap Inspection: Detecting defects.

- Different Cap Types: Adapting to bottle styles.

Dive deeper Paragraph:

The capping stage is a critical step in the juice bottling process, as it ensures that the filled bottles are securely sealed to prevent contamination and maintain freshness. Automated capping machines are employed to apply caps or closures to the bottles with precision and consistency. These machines are designed to handle a variety of cap types, including screw caps, snap caps, and tamper-evident closures, depending on the specific requirements of the juice product.

Labeling and Packaging: Final Touches

leading paragraph:

How does the juice get its appealing look and protection for shipping?

snippet paragraph:

Labeling involves applying labels with product information and branding. Packaging prepares the bottles for distribution, often using shrink-wrap or cardboard boxes, ensuring they arrive safely to consumers.

Labeling and Packaging Processes

- Label Application: Attaching product information.

- Branding: Enhancing product appeal.

- Shrink-Wrapping: Securing bottles in packs.

- Cardboard Boxing: Protecting bottles during transport.

- Automated Systems: Streamlining the process.

- Quality Control: Ensuring accuracy.

Dive deeper Paragraph:

The final stages of the juice bottling process involve labeling and packaging, which are essential for providing consumers with product information, enhancing brand appeal, and ensuring safe transportation of the bottled juice. Labeling involves applying labels to the bottles, typically containing information such as the product name, ingredients, nutritional facts, and manufacturer details. The labels also serve as a branding tool, allowing companies to showcase their logos, colors, and design elements to attract consumers.

Conclusion

From squeezing fruits to sealing bottles, the juice production line is a marvel of modern technology! Now you know the secrets behind your refreshing juice.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.