What is a Beverage Bottle Filling Machine?

leading paragraph:

Ever seen rows of bottles zipping through a factory, getting filled in seconds? That's the magic of filling machines!

snippet paragraph:

A beverage bottle filling machine is automated equipment used in the beverage industry to accurately and efficiently fill bottles, cans, or other containers with various beverages. They handle different container sizes and shapes, ensuring consistent product quality and minimizing waste, streamlining beverage manufacturing.

Transition Paragraph:

Let's explore the key features and functions of these essential machines.

Key Functions of a Beverage Bottle Filling Machine

leading paragraph:

What exactly does a bottle filling machine do?

snippet paragraph:

Key functions include: 1) Container infeed and alignment 2) Precise filling to a set level 3) Capping or sealing 4) Labeling

5) Quality control checks. These steps ensure a consistent, high-quality product.

Core Operations of a Filling Machine

- Container Infeed: Bottles or cans are fed into the machine.

- Alignment: Containers are properly positioned for filling.

- Filling: Precise amount of beverage is dispensed into each container.

- Capping/Sealing: Caps or lids are applied and sealed.

- Labeling: Labels are affixed to the containers.

- Quality Control: Checks for fill level, leaks, and proper sealing.

- Discharge: Filled and sealed containers are moved to the next stage.

Dive deeper Paragraph:

Beverage bottle filling machines perform several key functions to ensure efficient and accurate filling. The process starts with container infeed, where bottles or cans are fed into the machine, usually via a conveyor system. The containers are then aligned to ensure they are properly positioned for filling. Next, the filling process dispenses a precise amount of beverage into each container, using various filling mechanisms depending on the type of beverage and container. After filling, caps or lids are applied and sealed to prevent leakage and maintain product freshness. Labels are then affixed to the containers, providing product information and branding. Throughout the process, quality control checks are performed to ensure accurate fill levels, proper sealing, and the absence of leaks. Finally, the filled and sealed containers are discharged from the machine, ready for packaging and distribution.

Types of Beverage Bottle Filling Machines

leading paragraph:

Are all filling machines the same?

snippet paragraph:

Different types exist based on the beverage type and container: 1) Volumetric fillers (precise volume) 2) Gravity fillers (simple and reliable) 3) Pressure fillers (for carbonated drinks) 4) Aseptic fillers (Suitable for high protein products such as milk). The choice depends on the specific needs of the production line.

Common Types of Filling Machines

- Volumetric Fillers: Measure and dispense precise volumes, ideal for high-value products.

- Gravity Fillers: Use gravity to fill containers, simple and reliable for non-carbonated drinks.

- Pressure Fillers: Maintain pressure to prevent foaming, essential for carbonated beverages.

- Aseptic Fillers: Filling sterilized product into sterilized containers, extending shelf life.

Dive deeper Paragraph:

The type of beverage bottle filling machine used depends on the specific requirements of the beverage being filled and the type of container being used. Volumetric fillers measure and dispense precise volumes of liquid, making them ideal for high-value products where accuracy is critical. Level fillers fill containers to a consistent visual level, ensuring a uniform appearance on the shelf, and are particularly suitable for clear liquids. Gravity fillers use gravity to fill containers, offering a simple and reliable solution for non-carbonated drinks. Pressure fillers maintain pressure within the container to prevent foaming, making them essential for filling carbonated beverages like soda and sparkling water. Aseptic fillers are used for filling sterilized product into sterilized containers, extending shelf life.

Benefits of Using a Beverage Bottle Filling Machine

leading paragraph:

Why invest in a bottle filling machine?

snippet paragraph:

Benefits include: 1) Increased production speed 2) Improved accuracy and consistency 3) Reduced labor costs 4) Minimized product waste 5) Enhanced hygiene. These machines optimize the filling process, boosting efficiency and profitability.

Advantages of Automation

- Increased Speed: Fills bottles much faster than manual labor.

- Improved Accuracy: Dispenses precise amounts, reducing overfilling or underfilling.

- Reduced Labor Costs: Requires fewer workers, lowering operational expenses.

- Minimized Waste: Reduces spillage and product loss, saving money.

- Enhanced Hygiene: Automated process minimizes contamination risks.

- Consistency: Ensures every bottle is filled to the same standard.

Dive deeper Paragraph:

Investing in a beverage bottle filling machine offers numerous benefits for beverage manufacturers. These machines significantly increase production speed, allowing for a higher volume of bottles to be filled in a shorter amount of time. They also improve accuracy, dispensing precise amounts of liquid into each bottle, reducing overfilling or underfilling. By automating the filling process, manufacturers can reduce labor costs, as fewer workers are needed to operate the machines. Beverage bottle filling machines also minimize waste by reducing spillage and product loss, saving money on raw materials. Furthermore, these machines enhance hygiene by minimizing the risk of contamination, ensuring that the beverages are safe for consumption.

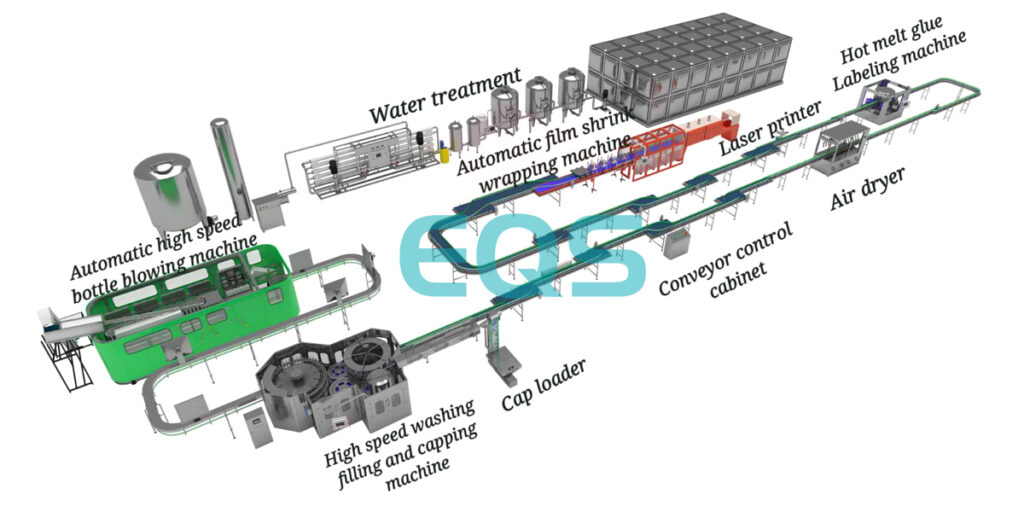

Components of a Typical Filling Machine

leading paragraph:

What parts make up a bottle filling machine?

snippet paragraph:

Typical components include: 1) Infeed conveyor 2) Filling heads 3) Capping station 4) Control panel 5) Outfeed conveyor. Understanding these components helps in maintenance and troubleshooting.

Key Parts of the Machine

- Infeed Conveyor: Transports empty containers into the machine.

- Filling Heads: Dispense the beverage into the containers.

- Capping Station: Applies and seals caps or lids onto the filled containers.

- Control Panel: Allows operators to control and monitor the machine's functions.

- Outfeed Conveyor: Transports filled and sealed containers out of the machine.

- Sensors: Detecting the presence of bottles for filling.

Dive deeper Paragraph:

A typical beverage bottle filling machine consists of several key components that work together to ensure efficient and accurate filling. The infeed conveyor transports empty containers into the machine, feeding them to the filling heads. The filling heads dispense the beverage into the containers, using various filling mechanisms depending on the type of machine. The capping station applies and seals caps or lids onto the filled containers, ensuring a tight and secure seal. The control panel allows operators to control and monitor the machine's functions, adjusting settings and troubleshooting issues. The outfeed conveyor transports the filled and sealed containers out of the machine, ready for packaging and distribution.

Materials Used in Beverage Bottle Filling Machines

leading paragraph:

What materials are these machines made from?

snippet paragraph:

Most machines are made from stainless steel for hygiene and durability. Other materials include food-grade plastics and rubber for seals and flexible components, ensuring compliance with safety standards.

Materials Used in Construction

- Stainless Steel: Used for most parts due to its corrosion resistance and hygienic properties.

- Food-Grade Plastics: Used for components that come into direct contact with beverages.

- Rubber Seals: Provide tight seals to prevent leaks.

- Aluminum: Used for some structural components due to its lightweight and strength.

- Glass: Used for encasing certain electronics or gauges.

Dive deeper Paragraph:

The materials used in beverage bottle filling machines are carefully selected to ensure hygiene, durability, and compliance with safety standards. Stainless steel is the most common material, used for most parts of the machine due to its excellent corrosion resistance and hygienic properties. Food-grade plastics are used for components that come into direct contact with beverages, ensuring that they do not contaminate the product. Rubber seals provide tight seals to prevent leaks, maintaining the integrity of the filling process. Aluminum is used for some structural components due to its lightweight and strength.

Conclusion

Beverage bottle filling machines are essential for modern beverage production. Understanding their definition, functions, types, and benefits helps manufacturers optimize their production lines for efficiency and quality.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.