How to Maintain a Bottled Water Filling Production Line?

Ever wonder how bottled water companies keep their production lines running smoothly? What if the secret lies in a combination of meticulous cleaning, careful lubrication, and regular inspections?

Maintaining a bottled water filling production line requires a multifaceted approach, including regular cleaning, proper lubrication, and diligent inspection of key components. This ensures the equipment operates efficiently and maintains the purity and quality of the bottled water. At EQS, we arrange for our engineers to visit customer sites for maintenance every year, ensuring everything runs smoothly.

Want to learn the best practices for keeping your bottled water production line in top condition? Keep reading to discover the essential maintenance tips that will help you maximize efficiency and product quality.

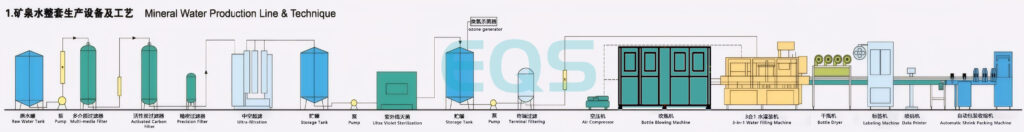

What is bottled water production process flow chart?

Are you curious about the journey of water from its source to the bottle? Do you want to understand the various stages involved in the bottled water production process?

The bottled water production process flow chart includes several key stages: water sourcing, purification, filling, capping, labeling, and packaging. Each stage is crucial for ensuring the purity, safety, and quality of the final product.

Bottled Water Production: A Step-by-Step Guide

Key Stages

- Water Sourcing: Water is sourced from natural springs, wells, or municipal sources.

- Purification: The water undergoes various purification processes to remove impurities and contaminants.

- Filling: Purified water is filled into sterilized bottles using automated filling machines.

- Capping: Bottles are immediately capped to prevent contamination and maintain purity.

- Labeling: Labels are applied to the bottles, providing information about the product and brand.

- Packaging: Labeled bottles are packaged into cases or shrink-wrapped for distribution.

Purification Methods

- Filtration: Removes sediment, particles, and microorganisms.

- Reverse Osmosis: Removes dissolved minerals and contaminants.

- UV Sterilization: Kills bacteria and viruses using ultraviolet light.

- Ozonation: Disinfects the water and enhances its purity.

Quality Control

| Stage | Quality Check | Purpose |

|---|---|---|

| Water Sourcing | Regular testing for contaminants and impurities | Ensures the water source meets quality standards |

| Purification | Monitoring the effectiveness of filtration and sterilization processes | Verifies that the purification methods are removing contaminants effectively |

| Filling | Checking fill levels and seal integrity | Ensures accurate filling and prevents leakage |

| Packaging | Inspecting labels for accuracy and packaging for damage | Guarantees accurate product information and protects the bottles during transportation |

I visited a bottled water plant once and was impressed by the meticulous quality control measures they had in place. They tested the water at every stage of the process to ensure it met the highest standards of purity.

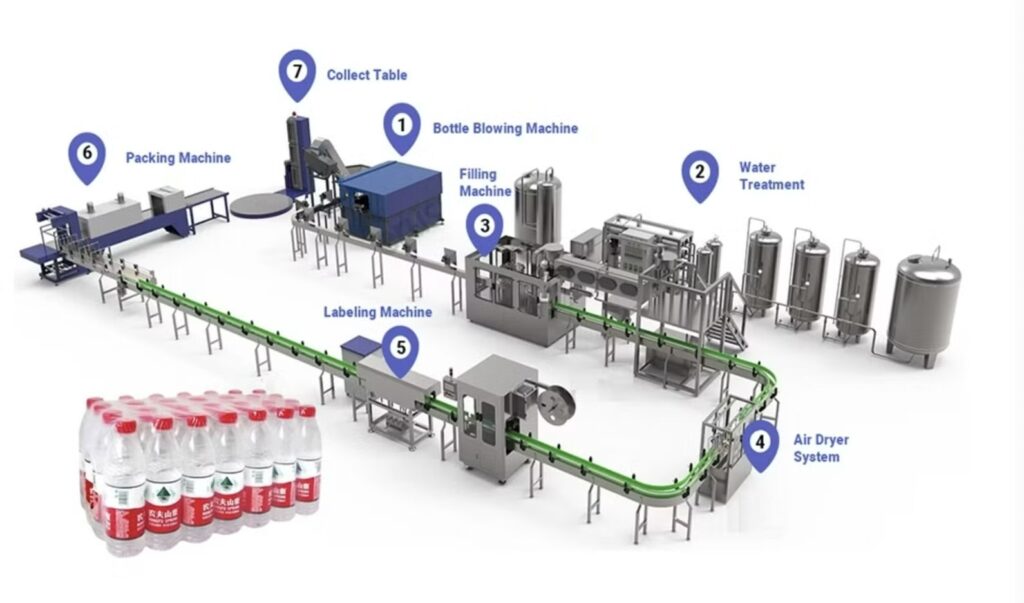

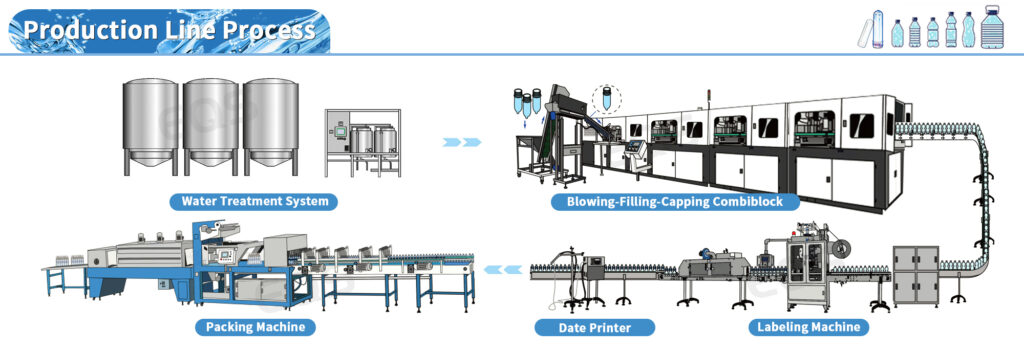

What is the water filling production line?

Are you wondering what equipment makes up a water filling production line? Do you want to know the specific functions of each component?

The water filling production line is a series of interconnected machines that automate the process of filling, capping, labeling, and packaging bottled water. Key components include water treatment systems, filling machines, capping machines, labeling machines, and packaging equipment.

Components of a Water Filling Production Line: Dive Deeper

Key Components

- Water Treatment System: Purifies the water to remove impurities and contaminants.

- Filling Machine: Fills the purified water into bottles.

- Capping Machine: Applies caps to the filled bottles.

- Labeling Machine: Applies labels to the bottles, providing product information.

- Packaging Equipment: Packages the labeled bottles into cases or shrink-wrapped bundles.

- Conveyor System: Transports bottles between different stages of the production line.

Types of Filling Machines

- Gravity Fillers: Use gravity to fill bottles, suitable for free-flowing liquids.

- Pressure Fillers: Use pressure to fill bottles, ideal for carbonated beverages.

- Volumetric Fillers: Fill bottles based on volume, ensuring accurate fill levels.

Automation and Efficiency

| Component | Function | Benefits |

|---|---|---|

| Filling Machine | Fills bottles with purified water | Ensures accurate fill levels, reduces spillage, and increases production speed |

| Capping Machine | Applies caps to filled bottles | Prevents contamination and maintains product integrity |

| Labeling Machine | Applies labels to bottles | Provides product information and enhances brand recognition |

| Packaging Equipment | Packages labeled bottles into cases or shrink-wrapped bundles | Facilitates efficient handling, storage, and transportation |

I've worked with many bottled water companies to design and install water filling production lines. It's amazing to see how these automated systems can streamline the production process and improve efficiency.

How do bottled water companies get their water?

Are you curious about the sources of water used by bottled water companies? Do you want to know the different types of water sources and how they are accessed?

Bottled water companies obtain their water from various sources, including natural springs, wells, and municipal water systems. Each source has its own characteristics and requires different treatment methods to ensure purity and safety.

Sources of Bottled Water: Dive Deeper

Types of Water Sources

- Natural Springs: Water that flows naturally to the surface from an underground source.

- Wells: Water extracted from underground aquifers using wells.

- Municipal Water Systems: Water sourced from public water systems, which may undergo further purification.

Accessing Water Sources

- Spring Collection: Water is collected directly from the spring source.

- Well Extraction: Water is pumped from underground wells.

- Municipal Supply: Water is drawn from the municipal water system.

Treatment Methods

| Water Source | Treatment Method | Purpose |

|---|---|---|

| Natural Springs | Filtration, UV sterilization, ozonation | Removes impurities and microorganisms while preserving the water's natural characteristics |

| Wells | Filtration, reverse osmosis, UV sterilization, ozonation | Removes dissolved minerals, contaminants, and microorganisms |

| Municipal Water Systems | Additional filtration, UV sterilization, ozonation | Removes any remaining impurities and ensures compliance with bottled water standards |

I remember visiting a natural spring water source and being impressed by the pristine environment and the natural purity of the water. It really highlighted the importance of protecting these natural resources.

What is the production of bottled water?

Are you wondering about the overall process of bottled water production, from sourcing to packaging? Do you want to understand the key steps and quality control measures involved?

The production of bottled water involves sourcing water, purifying it, filling it into bottles, capping the bottles, labeling them, and packaging them for distribution. Each step is carefully controlled to ensure the bottled water meets the highest standards of purity, safety, and quality.

The Complete Bottled Water Production Process: Dive Deeper

Key Steps

- Water Sourcing: Selecting and accessing the water source.

- Purification: Removing impurities and contaminants through various treatment methods.

- Filling: Filling sterilized bottles with purified water.

- Capping: Sealing the bottles to prevent contamination.

- Labeling: Applying labels with product information.

- Packaging: Packing the labeled bottles for distribution.

Quality Control Measures

- Regular Testing: Water is tested regularly for contaminants and impurities.

- Equipment Maintenance: Production equipment is maintained to ensure proper functioning.

- Hygiene Standards: Strict hygiene standards are enforced throughout the production process.

- Certification: Production facilities are certified to meet industry standards.

Importance of Maintenance

| Aspect | Importance | Benefits |

|---|---|---|

| Regular Cleaning | Prevents the buildup of contaminants and microorganisms | Ensures the purity and safety of the bottled water |

| Lubrication | Keeps equipment running smoothly and efficiently | Reduces wear and tear, minimizes downtime, and extends the lifespan of the equipment |

| Inspection | Identifies potential issues before they become major problems | Prevents costly repairs, minimizes downtime, and ensures consistent product quality |

At EQS, we understand the importance of regular maintenance for bottled water production lines. That's why we offer comprehensive maintenance services to our customers, including on-site visits from our experienced engineers. This proactive approach helps prevent issues before they arise, ensuring smooth and efficient production.

Conclusion

Maintaining a bottled water filling production line requires a comprehensive approach that includes regular cleaning, proper lubrication, and diligent inspection. By following these best practices, bottled water companies can ensure the efficiency, reliability, and safety of their production processes.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.