Maximize Your Water Bottling Efficiency with Advanced Filling Technology

Turnkey water bottling lines, incorporating European technology, with 20+ years of experience.

Your Trusted Partner in Water Bottling Technology

Global Reach

Serving major markets worldwide

High Filling Speed

Own Manufacturing

Complete quality control

COmplete Solution

Comprehensive Water Filling Solutions

We offer a range of solutions tailored to your specific needs, from individual machines to complete turnkey lines.

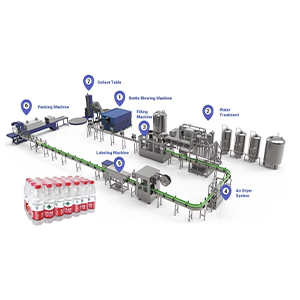

Turnkey Water Filling Lines

High-Performance Filling Machines

Amet minim mollit non deserunt ullamco est sit aliqua dolor do amet sint. Velit officia cons equat duis enim velit mollit.

Global Support & Service

Don't hesitate to contact us for more information.

jiangsu,suzhou zhangjiagang hexi rouad - china

All You Need to Know About Water Filling Machine

Our bottling lines are capable of handling high-speed production, with capacities up to 54,000 BPH (500ml), catering to both small and large volumes. Our innovative Blow-Fill-Cap Combiblock systems integrate blowing, filling, and capping into a single unit, reducing labor costs, minimizing contamination risks, and enhancing efficiency. Designed to handle various bottle sizes (100ml to 5L), our equipment ensures versatility, allowing you to adapt to market demands and expand your product range seamlessly.

Advantages Of Water Filling Line

Our bottling lines are capable of handling high-speed production, with capacities up to 54,000BPH (500ml). Whether you need to bottle small volumes or large quantities, our systems are designed to meet your demands.

Our integrated Blow-Fill-Cap system merges blowing, filling, and capping, boosting efficiency. This tech cuts labor, reduces contamination, and maximizes output. Streamlined, it optimizes flow and ensures quality.

Our equipment is designed to handle various bottle sizes and shapes, from small 100ml bottles to large 15L containers. This versatility allows you to adapt to market demands and expand your product range with ease.

Our premium water purification systems ensure bottled water of exceptionally high purity. Through advanced micro-filtration and sterilization processes, we provide comprehensive solutions for delivering safe, clean, and truly refreshing water.

How Do Water Filling Machine Work

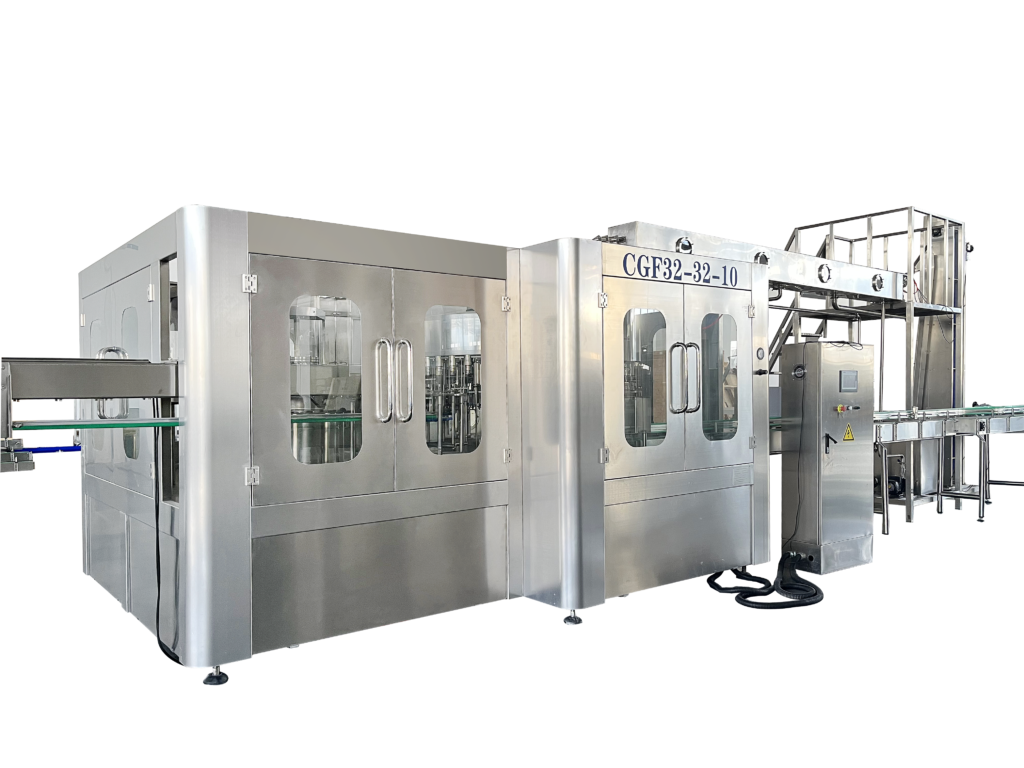

Washing Filling Capping Machine

This Water Filling Machine is designed for producing polyester bottled mineral water, purified water, drinking water, and other non-carbonated beverages. It streamlines the entire process, including rinsing, filling, and sealing, minimizing material waste, reducing external contact, and enhancing hygiene, production capacity, and efficiency.

Specifically suited for PET bottle water filling, it utilizes gravity filling and magnetic capping with stepless adjustable capping force. Controlled by a PLC system, it boasts a production capacity of 2000-24000 bottles per hour.

5 Gallon Water Filling Machine

This 5 Gallon water filling machine specially produces 5 gallons water bottle, whose types(b/h)are: 100 type, 200 type, 300 type, 450 type, 600 type, 900 type, 1200 type and 2000 type. This machine integrates bottle washer, filler and sealer into one unit, in order to achieve the purpose of multiple injections of washing and sterilizing by means of liquid washing and leaching are used in bottle washer, Washing solution can be used circularly.

The 5 Gallon filling machine sealer can seal bottle caps automatically. This line equips with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy, also this 5 gallon bottle filling machine can automatically carry out bottle feeding washing, sterilizing, filling, capping, counting and products discharging. It is a new kind of barrel water auto-producing line, which integrates mechanism, electricity and pneumatic technologies together.This 5 gallon water filling line is also can be used for 3 gallon water filling.

Blowing Filling Capping Machine

The Blowing-Filling-Capping Combiblock is one powerful combination, which completes the whole process from preform to bottled, It can decrease intermediate links such as conveying, empty bottle handling, stacking and storage processes, improve packaging sanitary conditions, reduce cross-contamination, increase overall operating efficiency, save energy consumption, so that it cuts overall production costs.

We integrates the industry’s most cutting-edge bottle blowing and filling technology to complement each other’s advantages. At the same time, we fully absorbed the core technology of COMAN to design and manufacture our own core product, the CGX series Combiblock which is simple to operate, stable and efficient, low energy consumption, and highly intelligent.

The production types range from small bottles (100ml) to 19L in barrels, and the production capacity per hour ranges from 2000 barrels (19L/B) to 54,000 bottles (500ML/B).