How to set up a small scale mineral water production plant?

Leading paragraph:

Dreaming of bottling your own mineral water? It's more attainable than you might think.

Snippet paragraph:

Setting up a small-scale mineral water production plant involves selecting a location near a good water source, obtaining necessary licenses, purchasing equipment for water treatment and packaging, implementing a quality control system, and creating a sales strategy.

Transition Paragraph:

Let's break down the steps to get your mineral water business flowing.

How do you manufacture mineral water?

Leading paragraph:

From source to bottle, the process of making mineral water is carefully controlled. How exactly is mineral water manufactured?

Snippet paragraph:

Mineral water is manufactured by extracting water from a natural source, filtering it to remove impurities while preserving its mineral content, and then bottling it under strict hygienic conditions. Regular testing ensures it meets quality standards.

Dive deeper Paragraph:

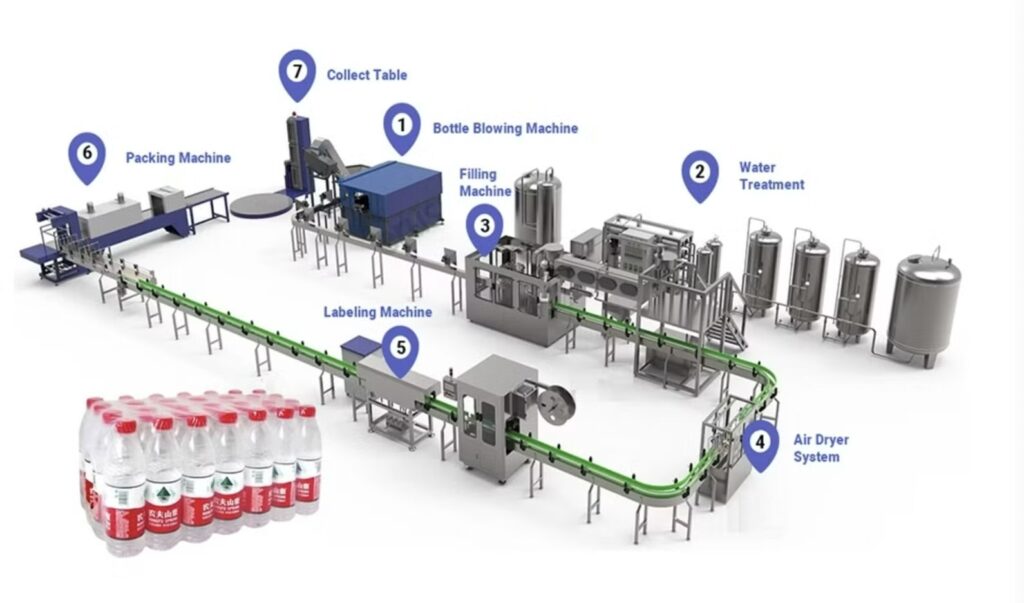

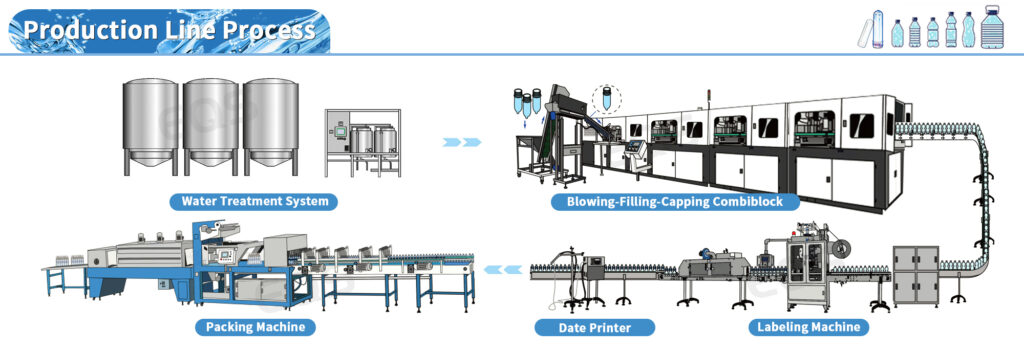

Here's a detailed look at the mineral water manufacturing process:

- Source Selection: Choosing a source with naturally mineral-rich water that meets regulatory standards is crucial. The water source needs to be tested regularly for purity and mineral content.

- Extraction: The water is extracted from the source using pumps and pipelines, ensuring minimal disturbance to the environment.

- Filtration: The extracted water is filtered to remove any impurities, such as sediment, bacteria, and other contaminants. This process typically involves multiple stages of filtration, including sand filters, carbon filters, and membrane filters.

- Bottling: The filtered water is then bottled in a hygienic environment, using automated filling and capping machines. The bottles are typically made of PET plastic or glass and are sterilized before filling.

-

Quality Control: Throughout the manufacturing process, regular testing is conducted to ensure that the mineral water meets quality standards. This includes testing for pH levels, mineral content, and the presence of any contaminants.

At EQS, we understand the importance of quality control in the beverage industry. Our filling machines are designed to ensure accurate and hygienic filling, helping you maintain the highest standards of product quality.

How much does it cost to start a water company?

Leading paragraph:

Turning your entrepreneurial dreams into reality requires careful financial planning. So, how much does it realistically cost to start a water company?

Snippet paragraph:

The cost to start a water company varies widely, ranging from \$50,000 to \$500,000 or more. It depends on factors like the scale of operation, equipment costs, location, and regulatory compliance expenses.

Dive deeper Paragraph:

Here's a breakdown of the potential costs involved in starting a water company:

- Equipment: Water treatment equipment, filling machines, bottling equipment, labeling machines, and packaging equipment can range from \$20,000 to \$200,000 or more, depending on the scale and automation level.

- Location: Renting or purchasing a facility can cost anywhere from \$5,000 to \$50,000 per year, depending on the location and size of the facility.

- Licenses and Permits: Obtaining the necessary licenses and permits can cost several thousand dollars, depending on the state and local regulations.

- Marketing and Sales: Developing a brand, creating marketing materials, and building a distribution network can cost anywhere from \$5,000 to \$50,000 or more.

-

Raw Materials: The cost of water, bottles, labels, and other raw materials will depend on the volume of production and the supplier.

It's essential to create a detailed business plan and budget to estimate the costs involved in starting a water company accurately.

How to start a water purification plant?

Leading paragraph:

Setting up a water purification plant requires careful planning and execution. What are the essential steps?

Snippet paragraph:

Starting a water purification plant involves conducting a feasibility study, securing funding, obtaining permits, purchasing purification equipment, establishing a quality control lab, and developing a distribution network.

Dive deeper Paragraph:

Here's a more detailed breakdown of the steps involved in starting a water purification plant:

- Feasibility Study: Conduct a thorough feasibility study to assess the market demand, identify potential water sources, and evaluate the financial viability of the project.

- Funding: Secure funding from investors, banks, or government grants.

- Permits: Obtain the necessary permits and licenses from local, state, and federal agencies.

- Equipment: Purchase water purification equipment, such as filters, reverse osmosis systems, and disinfection systems.

- Quality Control: Establish a quality control lab to test the purified water regularly and ensure that it meets all regulatory standards.

-

Distribution: Develop a distribution network to sell the purified water to customers.

Starting a water purification plant requires significant investment and expertise. It's essential to work with experienced professionals to ensure that the project is successful.

How much does it cost to build a bottling plant?

Leading paragraph:

The cost of building a bottling plant can be a significant investment. What factors influence the overall expense?

Snippet paragraph:

The cost to build a bottling plant can range from \$1 million to \$10 million or more, depending on the size of the plant, the level of automation, and the types of products being bottled.

Dive deeper Paragraph:

Here's a breakdown of the potential costs involved in building a bottling plant:

- Land and Construction: The cost of land and construction can vary widely depending on the location and size of the plant.

- Equipment: Bottling equipment, such as filling machines, capping machines, labeling machines, and packaging machines, can range from \$500,000 to \$5 million or more.

- Utilities: The cost of utilities, such as water, electricity, and gas, can be significant, especially for large-scale bottling plants.

- Labor: The cost of labor will depend on the number of employees needed to operate the plant.

-

Permits and Licenses: Obtaining the necessary permits and licenses can cost several thousand dollars, depending on the state and local regulations.

Building a bottling plant is a complex and expensive undertaking. It's essential to carefully plan the project and work with experienced professionals to ensure that it is successful.

Conclusion

Setting up a small-scale mineral water plant requires careful planning, securing funding, and adhering to quality standards, but can be a rewarding venture.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.