What is the working principle of 3 in 1 water filling machine?

Leading paragraph:

Ever wondered how those bottles get filled so quickly and efficiently? It's all thanks to the ingenious 3-in-1 filling machine!

Snippet paragraph:

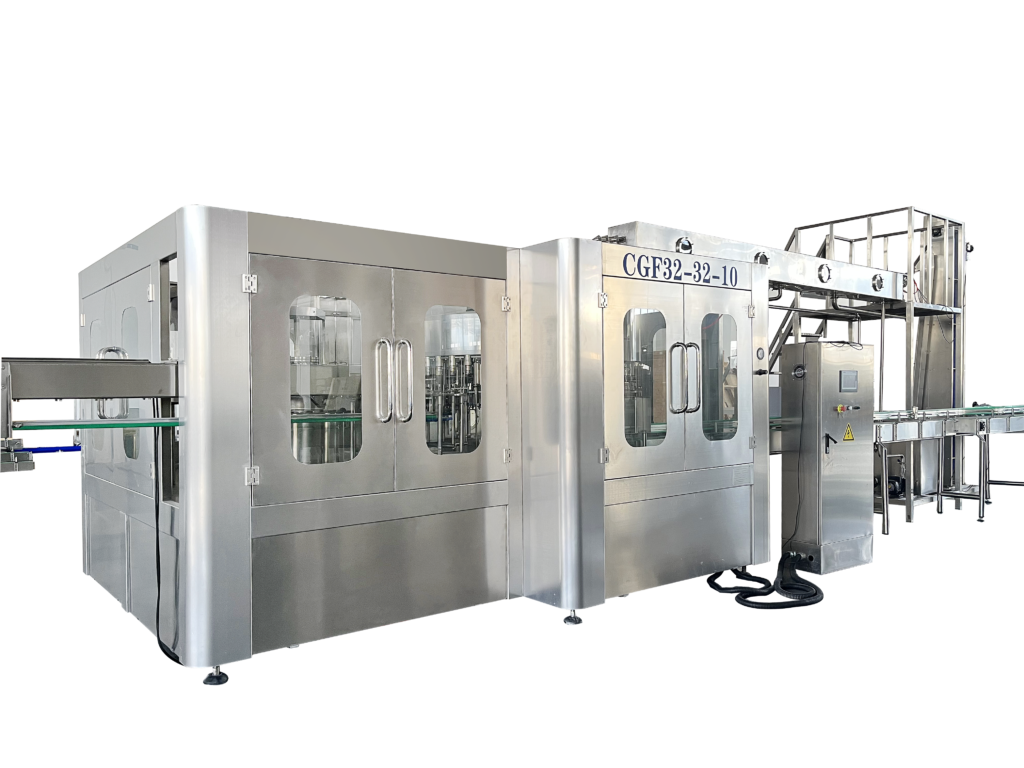

A 3-in-1 filling machine integrates bottle washing, filling, and capping into one compact system. Bottles are automatically cleaned, filled with liquid, and then sealed, all in a continuous process, saving space and increasing efficiency.

Transition Paragraph:

Let's explore how each of these functions works together to create a seamless filling process.

What is the principle of automatic liquid filling machine?

Leading paragraph:

Automatic liquid filling machines are the workhorses of modern beverage production. But how do they actually work?

Snippet paragraph:

Automatic liquid filling machines use various methods, such as volumetric filling, gravity filling, or pressure filling, to dispense precise amounts of liquid into containers. Sensors and controls ensure accuracy and consistency.

Dive deeper Paragraph:

The core principle of an automatic liquid filling machine is to accurately and consistently dispense a specific volume of liquid into a container. Several methods achieve this:

- Volumetric Filling: This method uses pistons, pumps, or cylinders to measure and dispense a precise volume of liquid. Sensors control the movement of these components, ensuring each container receives the correct amount.

- Gravity Filling: This method relies on gravity to fill containers. The liquid flows from a tank into the container, and the filling stops when the liquid reaches a pre-determined level. This is suitable for free-flowing liquids.

-

Pressure Filling: This method uses pressurized gas to force the liquid into the container.

Automatic liquid filling machines also incorporate sensors and control systems to monitor and adjust the filling process. These systems can detect errors, such as overfilling or underfilling, and make corrections in real-time. I've seen these machines in action, and the level of precision and automation is truly impressive. It's a far cry from the manual filling methods of the past!

What is the mechanism of a filling machine?

Leading paragraph:

From sensors to nozzles, every component plays a crucial role. Let's break down the mechanism of a filling machine.

Snippet paragraph:

A filling machine's mechanism involves a conveyor system to move containers, filling heads to dispense liquid, sensors to monitor levels, and a control system to coordinate all operations for precise filling.

Dive deeper Paragraph:

Let's dive into the key components and their roles:

| Component | Function |

|---|---|

| Conveyor System | Transports containers through the filling process |

| Filling Heads | Dispense liquid into the containers |

| Nozzles | Control the flow of liquid from the filling heads |

| Sensors | Monitor liquid levels, container presence, and other parameters |

| Control System | Coordinates all operations, including filling speed, volume, and timing |

| Programmable Logic Controller (PLC) | The "brain" of the machine, controlling all automated functions |

| Human-Machine Interface (HMI) | Allows operators to monitor and adjust settings |

The filling process starts with the conveyor system moving empty containers into the filling station. Sensors detect the presence of a container and trigger the filling heads to dispense liquid. The control system ensures that the correct volume of liquid is dispensed into each container. If a problem is detected, the control system can stop the machine and alert the operator. It’s a highly synchronized system, designed for maximum efficiency and minimal waste.

How does an automatic filling machine work?

Leading paragraph:

Automation is key to modern filling processes. But what exactly does an automatic filling machine do?

Snippet paragraph:

An automatic filling machine works by automatically conveying containers, filling them with a pre-set amount of liquid, and then moving them to the next stage, all without manual intervention, increasing speed and accuracy.

Dive deeper Paragraph:

Here's a step-by-step breakdown of how an automatic filling machine works:

- Container Loading: Empty containers are loaded onto a conveyor system, either manually or automatically.

- Container Detection: Sensors detect the presence of a container and signal the control system.

- Filling Process: The control system activates the filling heads, which dispense a pre-set amount of liquid into the container.

- Level Monitoring: Sensors monitor the liquid level in the container to ensure it reaches the correct fill point.

- Filling Completion: Once the container is filled, the filling heads stop dispensing liquid, and the container is released.

-

Conveyor Movement: The conveyor system moves the filled container to the next stage, such as capping or labeling.

Throughout this process, the control system continuously monitors various parameters, such as filling speed, liquid level, and container position. If any deviations are detected, the system can automatically adjust the filling process or stop the machine to prevent errors. This level of automation is crucial for maintaining high production rates and consistent product quality.

How does a water filling machine work?

Leading paragraph:

Water filling machines are essential for providing clean and safe drinking water on a large scale. So, what's the process?

Snippet paragraph:

Water treatment purifies water,water filling machine fills it into bottles, and seals them. It ensures that the water is free from contaminants and safe for consumption.

Dive deeper Paragraph:

Here’s how a typical water filling machine operates:

- Water Purification: The incoming water supply undergoes a series of purification processes, such as filtration, reverse osmosis, and UV sterilization, to remove impurities and microorganisms.

- Bottle Washing: Empty bottles are thoroughly washed and sanitized to ensure they are free from contaminants.

- Filling Process: Purified water is dispensed into the sanitized bottles using precise filling mechanisms.

- Capping: The filled bottles are immediately capped and sealed to prevent contamination.

-

Quality Control: The filled and sealed bottles undergo quality control checks to ensure they meet safety standards.

The entire process takes place in a controlled environment to minimize the risk of contamination. Water filling machines are designed to meet strict hygiene standards and are regularly cleaned and sanitized. These machines are essential for ensuring that the water we drink is safe and of high quality.

Conclusion

The 3-in-1 water filling machine is a marvel of engineering, streamlining the bottling process. It ensures efficiency and hygiene in beverage production.

My name is Allen, and I'm an expert in filling machine technology at EQS (www.eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your beverage production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.