Parallel Robot Machine

With the mission of “liberating hands with technology”, we focus on the research and innovation of intelligent manufacturing technologies such as parallel Delta robots, high-speed SCARA robots, autonomous controllers, and vision systems, and have developed into a leading expert in high-speed robots in the industry.

Always committed to providing high-speed robot products and automated intelligent solutions to integrator customers in the new energy sub sectors such as food, pharmaceuticals, daily chemicals, 3C, PCB, photovoltaics, and lithium batteries, helping customers achieve cost reduction and efficiency improvement

Atomrobot Series Product

High Speed:

The maximum beat can be stabilized at 600 beats per minute. A single robot can save 3-5 manual labor and replace 2-4 traditional sorting equipment.

High Precision:

Even under high-speed conditions (300 times/min or more), the repeated positioning accuracy can still reach ± 0.02mm. It is more suitable for high-precision sorting, assembly, and other operations at high speeds.

High Durability:

High-precision sliding tiger hinge, balancing high precision, high applicability, and professionalism, with a tested wear resistance of 20,000 hours. The core components are easy to install, have a strong load capacity, and can have a service life of up to 8 years.

High Stability:

The body is maintenance-free throughout the year, and no additional lubrication or maintenance is required for each joint. The pre-tensioned structure has no gaps. The structural design is simple, and the assembly connection is stable and reliable.

High Speed & Precision:

High speed Japanese servo motors bring a maximum operating cycle of 240ppm. Customized one arc reducer ensures a repeat positioning accuracy of ± 0.02mm. Equipped with German imported synchronous belts and pulleys, it provides over 2 years of maintenance free and precision maintenance time.

Application:

A planar articulated robot developed for high-speed and high-precision sorting processes, with spatial four degrees of freedom for translation along the XYZ three directions and rotation around the Z-axis.

Modular Design & Performance:

The robot adopts a modular design as a whole, and the core reducer has the characteristics of high precision, ultra quiet, and high lifespan, providing strong support for large loads and high speeds. With the use of high-speed motors, the maximum speed can reach 240ppm, and the repeatability accuracy is about 0.02mm.

Integration & Flexibility:

The body adopts internal wiring, with strong integration and a protection level of up to IP65. The external interface positions are diverse and can be installed and lifted, which can be flexibly applied to various application scenarios.

Simple Programming:

Novices can master programming methods in 30 minutes, featuring visual programming and a simple and efficient user interface. Ordinary workers can operate independently after 0.5 days of training.

Widely Used:

Widely used in food, medicine, 3C, daily chemical, precision installation, product packaging, polishing, handling, welding, assembly, spraying, stacking and other fields.

Flexible Production:

Multiple functional scenarios can be quickly switched, and flexible production can be achieved through human-machine collaboration, dual machine collaboration, and multi machine collaboration.

Safe and Stable:

Supports 10 level collision detection to avoid accidental injury to workers. In the event of a single failure of the collision damaged equipment, the safety function will not be lost and the end will not drop due to power failure. The product is safe and stable.

Intelligent Automation:

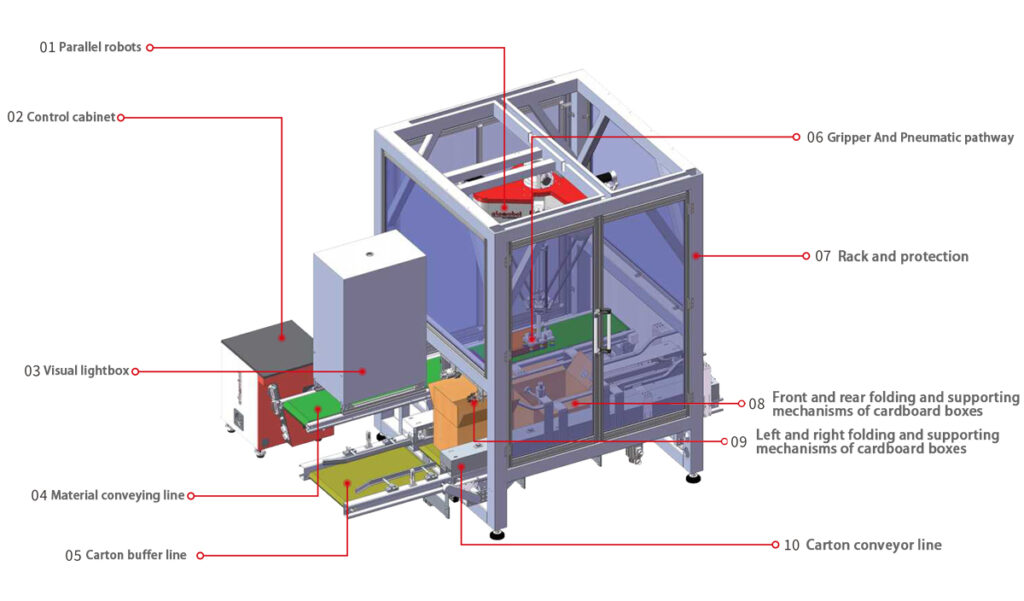

Equipped with a fully self-developed visual system, the workstation seamlessly integrates with material and empty box conveying lines at the front-end. The backend connects to sealing, weighing, and coding equipment to achieve precise and efficient opening, sealing, and fully automated packaging of various materials such as large-scale subcontracting, inflatable packaging, vacuum packaging, and liquid tape.

Modern Design:

Features a brand-new design, boasting a beautiful appearance and compact structure.

Customizable Robot Models:

Robot models can be customized according to different load requirements and handling ranges.

Easy Operation & Versatility:

Supports multi-size specification adaptation with a one-click start for easy operation.

Efficient Deployment:

Flexible adaptation of end effectors based on material size ensures more efficient deployment.

Enhanced Safety & Reliability:

Incorporates additional safety functions such as safety door protection, leak detection alarm, and material recycling, ensuring a safe and reliable operation.