7 Must-Know Features When Selecting a Water Filling Machine

leading paragraph:

Quench your thirst for knowledge! Key features for water fillers.

snippet paragraph:

Selecting the right water filling machine involves considering seven key features: filling method, container compatibility, filling speed, precision and consistency, leak-prevention mechanisms, ease of use and maintenance, and compatibility with other systems. These features ensure efficient and reliable water filling operations.

Transition Paragraph:

Let's dive into these seven crucial features to help you make the best choice for your water filling needs.

Filling Method: Choosing the Right Technique

leading paragraph:

How does it fill? The method matters!

snippet paragraph:

Different filling methods include volumetric, gravity, and pressure filling. Volumetric filling is accurate for consistent volumes, gravity filling is cost-effective for free-flowing liquids, and pressure filling handles carbonated water efficiently. Select the method that suits your water type and production needs.

Filling Methods

- Volumetric Filling: Accurate and precise.

- Gravity Filling: Cost-effective option.

- Pressure Filling: For carbonated water.

- Flow Meter Filling: Controlled dispensing.

- Net Weight Filling: Measuring by weight.

- Level Filling: Filling to a specific height.

Dive deeper Paragraph:

When selecting a water filling machine, the filling method is a critical factor to consider, as it directly impacts the accuracy, speed, and suitability of the machine for different types of water. Volumetric filling is one of the most common and accurate methods used in the industry. This method involves dispensing a precise volume of water into each container, ensuring consistent fill levels and minimizing product waste.

Container Compatibility: Handling Different Shapes and Sizes

leading paragraph:

Will it fit? Consider your containers!

snippet paragraph:

Ensure the machine can handle various container shapes and sizes, including bottles, jugs, and pouches. Adjustable settings and versatile designs accommodate diverse packaging needs, providing flexibility in your product offerings.

Container Considerations

- Bottle Shapes: Round, square, custom.

- Bottle Sizes: Small to large formats.

- Jug Compatibility: Handling larger containers.

- Pouch Filling: Versatile options.

- Adjustable Settings: Adapting to changes.

- Material Types: Glass, plastic, etc.

Dive deeper Paragraph:

Container compatibility is a crucial consideration when selecting a water filling machine, as it determines the machine's ability to handle different shapes and sizes of bottles, jugs, and pouches. The versatility of the filling machine in accommodating various container types directly impacts your production flexibility and the range of products you can offer.

Filling Speed: Meeting Your Production Demands

leading paragraph:

How fast can it go? Speed is key!

snippet paragraph:

Evaluate the machine's filling speed to meet your production demands. High-speed machines are ideal for large-scale operations, while slower machines are suitable for smaller businesses. Choose a machine that aligns with your output requirements.

Speed Factors

- Bottles Per Minute: Measuring output.

- Production Volume: Meeting targets.

- Machine Capacity: Handling large runs.

- Automation Level: Streamlining process.

- Downtime Impact: Minimizing interruptions.

- Scalability: Adapting to growth.

Dive deeper Paragraph:

Filling speed is a critical parameter to consider when selecting a water filling machine, as it directly impacts your production capacity and ability to meet market demands. The filling speed of a machine is typically measured in bottles per minute (BPM) and indicates how many bottles the machine can fill within a given timeframe.

Precision and Consistency: Ensuring Accurate Fills

leading paragraph:

Every drop counts! Accurate filling is essential.

snippet paragraph:

Precision and consistency ensure accurate fills and minimize product waste. Look for machines with precise measurement systems and automated controls to maintain uniform fill levels in every container.

Accuracy Measures

- Measurement Systems: Precise dispensing.

- Automated Controls: Consistent levels.

- Fill Level Sensors: Monitoring accuracy.

- Calibration: Maintaining precision.

- Error Margin: Acceptable variance.

- Product Waste: Minimizing losses.

Dive deeper Paragraph:

Precision and consistency are paramount when it comes to water filling, as they directly impact product quality, consumer satisfaction, and operational efficiency. Accurate fills ensure that each container receives the correct amount of water, preventing underfilling or overfilling, which can lead to product waste and customer dissatisfaction.

Leak-Prevention Mechanisms: Avoiding Spills and Waste

leading paragraph:

No leaks allowed! Prevent spills and waste.

snippet paragraph:

Effective leak-prevention mechanisms are crucial for minimizing spills and waste. Look for machines with tight seals, anti-drip nozzles, and overflow sensors to maintain a clean and efficient filling environment.

Prevention Features

- Tight Seals: Preventing leaks.

- Anti-Drip Nozzles: Avoiding drips.

- Overflow Sensors: Monitoring levels.

- Spill Containment: Managing spills.

- Emergency Stops: Quick shutdowns.

- Safety Guards: Protecting workers.

Dive deeper Paragraph:

Leak-prevention mechanisms are essential components of a water filling machine, as they directly contribute to minimizing spills, waste, and maintaining a clean and safe filling environment. Effective leak prevention measures not only reduce product loss but also help prevent potential hazards, such as slippery floors, and ensure a smooth and efficient filling process.

Ease of Use and Maintenance: Streamlining Operations

leading paragraph:

Simple is best! Easy to use and maintain.

snippet paragraph:

Choose a machine that is easy to operate and maintain, with intuitive controls, accessible components, and clear instructions. Simplified operations reduce training time and maintenance costs, improving overall efficiency.

User-Friendly Design

- Intuitive Controls: Simple operation.

- Accessible Components: Easy maintenance.

- Clear Instructions: Quick setup.

- Easy Cleaning: Hygienic design.

- Quick Changeover: Adapting to products.

- Remote Monitoring: Tracking performance.

Dive deeper Paragraph:

Ease of use and maintenance are crucial factors to consider when selecting a water filling machine, as they directly impact the operational efficiency, training requirements, and long-term costs associated with the equipment. A user-friendly machine can significantly reduce the learning curve for operators, minimize errors, and streamline the filling process, leading to increased productivity and reduced labor costs.

Compatibility with Other Systems: Integration and Automation

leading paragraph:

Play well with others! System compatibility matters.

snippet paragraph:

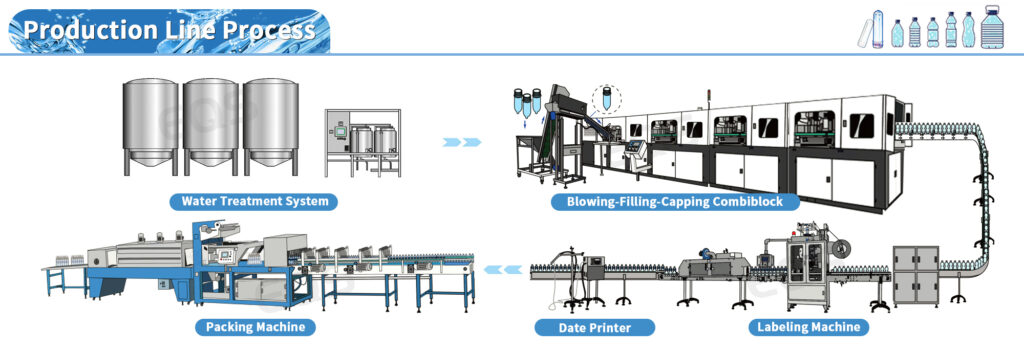

Ensure the machine is compatible with your existing systems, such as conveyors, labeling machines, and packaging equipment. Seamless integration enhances automation, reduces manual handling, and optimizes your production line.

System Integration

- Conveyor Systems: Smooth transfer.

- Labeling Machines: Automated labeling.

- Packaging Equipment: Efficient packaging.

- Control Systems: Centralized control.

- Data Integration: Performance tracking.

- Robotic Integration: Automated handling.

Dive deeper Paragraph:

Compatibility with other systems is a critical consideration when selecting a water filling machine, as it determines the machine's ability to integrate seamlessly into your existing production line. A water filling machine that is compatible with your other systems, such as conveyor systems, labeling machines, and packaging equipment, can significantly enhance automation, reduce manual handling, and optimize your overall production process.

Conclusion

Choosing the right water filling machine means considering these 7 features. Investing in a machine with these features will optimize your water filling operations.

My name is Allen, and I'm an expert in filling machine technology at EQS (eqsfilling.com), a leading liquid packaging solution provider based in China. If you're looking for top-quality filling machines for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.